Welcome to Club Cobra! The World's largest

non biased Shelby Cobra related site!

- » Representation from nearly all

Cobra/Daytona/GT40 manufacturers

- » Help from all over the world for your

questions

- » Build logs for you and all members

- » Blogs

- » Image Gallery

- » Many thousands of members and nearly 1

million posts!

YES! I want to register an account for free right now!

p.s.: For registered members this ad will NOT show

Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

November 2025

November 2025

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

|

1 |

| 2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 9 |

10 |

11 |

12 |

13 |

14 |

15 |

| 16 |

17 |

18 |

19 |

20 |

21 |

22 |

| 23 |

24 |

25 |

26 |

27 |

28 |

29 |

| 30 |

|

|

|

|

|

|

|

CC Advertisers

CC Advertisers

|

|

2Likes 2Likes

07-03-2007, 08:20 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

|

-

Advertising

07-03-2007, 08:23 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Now it is time to give the motor the one over and make sure everything is OK. We always check the parallelism of the harmonic balancer pulley to the water pump pulley and we found this one was a little bit off. See the cool tool we use to make sure everything is in line? Peter Brock showed me that trick years ago. He told me they were loosing belts during races until someone figured out why.

|

07-03-2007, 09:53 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Well, as you can see, my guys are putting the car together faster than I can type and comment. I can see I am going to have to probably do this over 2 cars. We are building an identical one to this one right now. It is in sanding right now. Hey, that gives me an idea...maybe I should do this for sanding and polishing a car as well.

Here is the engine in the car.

|

07-19-2007, 06:52 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Finally a few minutes to get back to the assembly manual! Lots of sales this week. Mostly from overseas.

Everyone likes to put the Tremec 5 speed in today. It is WAY better than the top-loader 4 speed transmission. I really don't like to drive the 4 speed cars any more.

To use the Tremec transmission, you MUST change the input shaft to the shorter shaft. Many transmission shops can do this for you...but WHY? When you can have all the fun yourself and convince your wife you NEED to buy MORE TOOLS!!!

So, you have to do a few things to be able to use your brand new TKO 600 tranny. We will start with the input shaft. It is the hardest thing to do and I always start with the hard things first. Kinda like when I start a new Chopin piece on the piano...I alway start with the "Presto con Fuoco"  That way when I am tired I can do the easy stuff.

The first area to address is the input shaft. So, how do I change the input shaft on my Tremec TKO 600 transmission?

Just grab a cold one and I will give you the step by step procedure.

First, take off the input shaft snout. You will need a 1/2 socket for this.

Last edited by David Kirkham; 07-20-2007 at 06:00 PM..

|

07-19-2007, 07:04 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

When you get all the bolts out, GENTLY pull the snout off. If you pull it too forcefully, who knows what all will come out with it--like the input shaft and its accompanying needle bearings. The input shaft is only held into the transmission by the snout and it can fall out right now onto your dirty floor that you forgot to clean up.

Bearings are just like peanut butter sandwiches...the peanut butter ALWAYS falls peanut butter face DOWN and bearings always stop rolling (under the bench) in the biggest pile of dirt and shavings they can find. But you can always think on the bright side--if you get junk in your bearing then you will get ANOTHER opportunity to read my manual as you pull out your transmission to change the input bearing from early failure

Be careful!

Last edited by David Kirkham; 07-20-2007 at 05:16 PM..

|

07-19-2007, 07:06 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Now put your freshly removed collar on the table next to your new, shorter collar. Remember, you want to put the SHORTER input shaft back in so keep them straight! This is one instance where shorter is better.

Last edited by David Kirkham; 08-03-2007 at 10:46 PM..

|

07-19-2007, 07:10 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

BE CAREFUL!!! There are shims in there! We will be using them shortly!

Last edited by David Kirkham; 07-20-2007 at 05:43 PM..

|

07-19-2007, 07:12 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

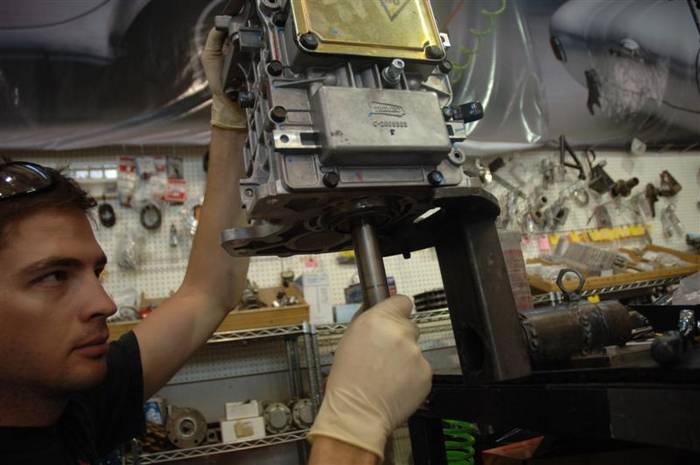

At this point, we cheat. If you notice, Sandwich is smiling. He is smiling because he has his Tremec TKO 600 on a special bench fixture that allows him to rotate the transmission in various positions to make working on it easier.

Sandwich rotates the transmission into a vertical position while HOLDING ON TO THE INPUT SHAFT and...

Last edited by David Kirkham; 07-20-2007 at 05:43 PM..

|

07-19-2007, 07:16 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

very carefully pulls out the input shaft. DON'T shake things around or yank on things, or jerk on the shaft! Just gently work it out.

Last edited by David Kirkham; 07-20-2007 at 05:42 PM..

|

07-19-2007, 07:18 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Now is not a good time to take a phone call. This is where things start to fall apart. Notice the input shaft bearing race just fell out.

Last edited by David Kirkham; 07-20-2007 at 05:42 PM..

|

07-19-2007, 07:22 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Now, THIS IS WHY WE HAVE BEEN SO CAREFUL ALL ALONG!!! See the needle bearings in the back of the input shaft? They like to play Hide-and-Seek with you. Usually they end up in the pile of shavings (that you STILL haven't cleaned up) or even better yet--THEY LIKE TO DISAPPEAR INTO THE TRANSMISSION as you are pulling the shaft out. Then you get to go fishing with a magnet for an hour until you get frustrated and take the top off of the transmission to find that last lost bearing!

WHEN YOU GET THE INPUT SHAFT FINALLY OUT, TAKE THE NEEDLE BEARINGS OUT AND PLACE THEM IN A CLEAN, CLEAN, CLEAN, PLACE; LIKE A NEW PAPER TOWEL--we will be using them again. (See, the "Presto con Fuoco" is looking easier all the time  ).

Last edited by David Kirkham; 07-20-2007 at 06:02 PM..

|

07-19-2007, 07:24 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Now you can set your long input shaft by your short input shaft and see the differences. You can also see the collar length differences as well.

Last edited by David Kirkham; 07-20-2007 at 05:43 PM..

|

07-19-2007, 07:28 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Now it is time to CLEAN!!!

In church they tell us "Cleanliness is next to Godliness" and if you don't clean things, you will have leaks and say things that are not very Godly.

Here Sandwich is taking a NEW razor and scraping off all of that yummy red goo that Tremec seals their transmissions up with. It MUST be perfectly clean--unless you like puddles of yucky red tranny goo on your floor (mixed with your shavings.)

|

07-19-2007, 07:31 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Back to the input collar.

Notice Tremec was nice enough to send you a new seal with your new input shaft and collar. Tremec was also very nice and covered the collar with a greasy film to prevent it from rusting. If you press the seal into the greasy collar, then the seal will not SEAL and your Chariot of Fire will mark its territory--as well as your clutch and then you will probably teach yourself (and your neighbors) new vocabulary words.

The red stuff around the outside of the seal is actually a glue that seals the outboard ring of the seal to the input shaft collar. The glue won't stick to grease--SO, you get to clean AGAIN!!!

|

07-19-2007, 07:34 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

|

07-19-2007, 07:37 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

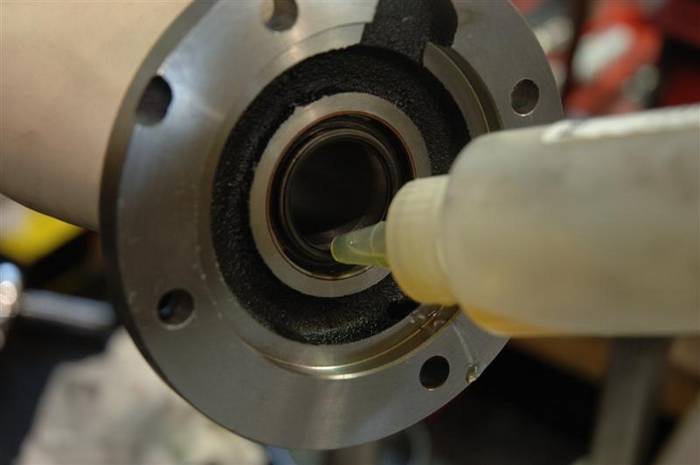

Now you can press the new seal in. You MUST press the seal in with a FLAT press tool. If you cock the seal or bend the seal, it WILL leak and you might as well save yourself the headache and go to the local seal shop and buy yourself a replacement. You can replace it now...or later after everything is buttoned up.

|

07-19-2007, 07:38 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Remember to put a little lube (we use motor oil) on the seal. Shafts hate to run dry. Your shaft will tear out the seal if it is dry. Notice Sandwich got a little too much oil on the seal and it is running down the face of the collar. That will have to be cleaned off or the collar will leak.

|

07-19-2007, 07:43 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Now you can clean the yummy red goo off of the input bearing race. You will have to use a razor to get it off.

|

07-19-2007, 07:47 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Now you can take the shims out of the old collar and put them into the new collar. In theory, you should measure the distance from the face of the input collar to the shims and make them the same between the input collars. The shims are there to put the proper preload on the input shaft bearing. If you have them too loose, the bearing will rattle around and live a very unhappy life. If the bearing is loaded too tight, it will burn up in short order. We usually just take a quick measurement to make sure things are OK. We have never found a problem...BUT, you better measure, just in case. Notice everything is CLEAN that Sandwich is working on. The old (longer) input collar is on the right in this picture.

|

07-19-2007, 07:50 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Now you can install the old race into the new input collar. Make sure everything is CLEAN! It should just drop into place with nothing more than a slight tap--if anything. DO NOT FORCE THE RACE!!! Or, anything else for that matter.

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 01:45 AM.

|

|

2Likes

2Likes

That way when I am tired I can do the easy stuff.

That way when I am tired I can do the easy stuff.

Linear Mode

Linear Mode