Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

|

1 |

| 2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 9 |

10 |

11 |

12 |

13 |

14 |

15 |

| 16 |

17 |

18 |

19 |

20 |

21 |

22 |

| 23 |

24 |

25 |

26 |

27 |

28 |

|

|

CC Advertisers

CC Advertisers

|

|

10-05-2009, 07:10 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jan 1999

Location: MARKSVILLE,LA.,,

Posts: 3,235

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by onefastmustang

Unless I have gone blind I am not seeing any specs on my cam card about springs. I sent the parts list to KC. I will see what he has to say about them.

|

On my Comp Cam cam card they gave the recommended spring pressures for seat pressure and open pressure..... If you're running a Ford Racing camshaft and you're running the Ford Racing springs, you could call the Ford Racing tech line and ask them for their recommended installed spring height and seat pressure.....

I would defiently check this to find out exactly how your springs are set up before putting things back together..

David

__________________

DAVID GAGNARD

|

10-05-2009, 07:34 PM

|

|

CC Member

|

|

|

Join Date: Jun 2005

Location: Fairfield,

ca

Cobra Make, Engine: CRII with a Stroked Windsor

Posts: 976

|

|

Not Ranked

Not Ranked

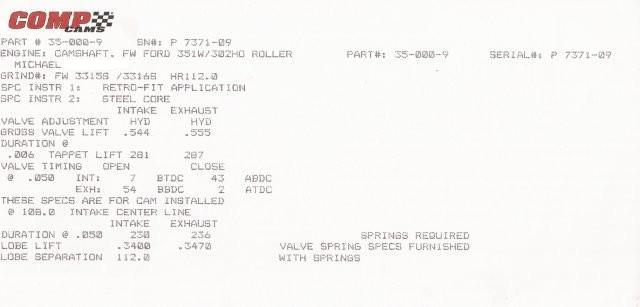

Here is my cam card.. All that is says are that springs are requred.. LOL

|

10-05-2009, 08:10 PM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: St. Louisville,

Oh

Cobra Make, Engine: A&C 67 427 cobra SB

Posts: 2,445

|

|

Not Ranked

Not Ranked

I'm no expert. Well let's put it this way. I don't get bothered at night by a phone ringing off the wall with people offering me big bucks to work in their engine shop. With that said here is my logic on the lifters. When the cam is pushing up on the lifter's roller and the pushrod is pushing down on the top of the lifter (via spring pressure), the forces on the roller pin are exactly the opposite of the piece that broke off.

Unless the roller pin is bent, excessive spring pressure is not going to cause this. If the pin flexed and did not yield (spings back to straight) it might cause this, but as small as these parts are I just wouldn't think this could happen to good parts at any reasonable spring loads. I would think that type of spring pressure would collapse the lifter. I may be wrong on that, but intuitively that would be what I would expect.

Since I cannot think of anything, other than flexing or bending of the roller pin. that would put a force in the direction needed to cause this break. I am thinking sub standard material or machine work. I would blame the lifter until something else is proven to have caused this.

Last edited by olddog; 10-05-2009 at 08:35 PM..

|

10-05-2009, 08:38 PM

|

|

CC Member

|

|

|

Join Date: Jun 2005

Location: Fairfield,

ca

Cobra Make, Engine: CRII with a Stroked Windsor

Posts: 976

|

|

Not Ranked

Not Ranked

Well I think I figure out what caused this.. the initial issue was a few months ago when my eccentric came lose and unscrewed the cam bolt. I had it at that time with my mechanical pump and pulled the eccentric out. But when the came bolt came loose it was enough to push the cam back into the block a few mm to make the adjacent lobe impact the front of the neighboring lifter. This explains why every lifter has a slight blemish or a full crack on the front side of the lifter but not the back. What clued me into this was the fact that not only was the casing damaged on the broken one but the pin had a wear mark in it that was in an arc which meant whatever was hitting it was rotating. I looked at the came and there is no apparent issue there so I think I am safe there. Oh well.. Live and learn. New lifters will be here tomorrow  . |

10-05-2009, 08:41 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jan 1999

Location: MARKSVILLE,LA.,,

Posts: 3,235

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by olddog

I'm no expert. Well let's put it this way. I don't get bothered at night by a phone ringing off the wall with people offering me big bucks to work in their engine shop. With that said here is my logic on the lifters. When the cam is pushing up on the lifter's roller and the pushrod is pushing down on the top of the lifter (via spring pressure), the forces on the roller pin are exactly the opposite of the piece that broke off.

Unless the roller pin is bent, excessive spring pressure is not going to cause this. If the pin flexed and did not yield (spings back to straight) it might cause this, but as small as these parts are I just wouldn't think this could happen to good parts at any reasonable spring loads. I would think that type of spring pressure would collapse the lifter.

Since I cannot think of anything, other than flexing or bending of the roller pin. that would put a force in the direction needed to cause this break. I am thinking sub standard material or machine work. I would blame the lifter until something else is proven to have caused this.

|

I'm certainly no engineer, but since the camshaft is turned by the timing chain, turned by the crankshaft, I would think more pressure could be put on the lifter/pushrod/rocker arm than the opposing spring pressure,causing two different amounts of pressure against the pin/roller of the lifter...I would also guess the roller pin is made of some serouis material, and the outside of the lifter (broken piece) that holds the pin in place would be the "weak link" here....the lifter could/would collaspe till it bottoms out and acts as a solid lifter, then there is no "give".

It's possible, might be a stretch, but possible.. I agree, probably a bad lifter, but given those Ford lifters are used in some serouis motors, it's rare to see them fail the way this one did.....Could be some other unkown "thing" contributed to the lifters failure. I wonder what the camshaft lobe looked like????

David

__________________

DAVID GAGNARD

|

10-05-2009, 08:47 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jan 1999

Location: MARKSVILLE,LA.,,

Posts: 3,235

|

|

Not Ranked

Not Ranked

[quote=onefastmustang;990483]Well I think I figure out what caused this.. the initial issue was a few months ago when my eccentric came lose and unscrewed the cam bolt. I had it at that time with my mechanical pump and pulled the eccentric out. But when the came bolt came loose it was enough to push the cam back into the block a few mm to make the adjacent lobe impact the front of the neighboring lifter. This explains why every lifter has a slight blemish or a full crack on the front side of the lifter but not the back. What clued me into this was the fact that not only was the casing damaged on the broken one but the pin had a wear mark in it that was in an arc which meant whatever was hitting it was rotating. I looked at the came and there is no apparent issue there so I think I am safe there.

Ah ha, now the rest of the story..........glad you got it figured out, at least you can fix it, it's when you can't find the problem, then you don't know what to fix........

Quote:

|

Oh well.. Live and learn.

|

Been there, done that, too many times..........

David

__________________

DAVID GAGNARD

|

10-05-2009, 08:53 PM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: St. Louisville,

Oh

Cobra Make, Engine: A&C 67 427 cobra SB

Posts: 2,445

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by onefastmustang

Well I think I figure out what caused this.. the initial issue was a few months ago when my eccentric came lose and unscrewed the cam bolt. I had it at that time with my mechanical pump and pulled the eccentric out. But when the came bolt came loose it was enough to push the cam back into the block a few mm to make the adjacent lobe impact the front of the neighboring lifter. This explains why every lifter has a slight blemish or a full crack on the front side of the lifter but not the back. What clued me into this was the fact that not only was the casing damaged on the broken one but the pin had a wear mark in it that was in an arc which meant whatever was hitting it was rotating. I looked at the came and there is no apparent issue there so I think I am safe there. Oh well.. Live and learn. New lifters will be here tomorrow  . |

That would make sense to me. I think you figured it out.

If the cam ran that far back for a while, it may have let the distributor gear alignment with the cam gear get out of whack. Since your luck has been questionable lately, you might want to give those gears a good hard look. I hope there are no issues. Good luck.

|

10-05-2009, 08:58 PM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: St. Louisville,

Oh

Cobra Make, Engine: A&C 67 427 cobra SB

Posts: 2,445

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by DAVID GAGNARD

I'm certainly no engineer, but since the camshaft is turned by the timing chain, turned by the crankshaft, I would think more pressure could be put on the lifter/pushrod/rocker arm than the opposing spring pressure,causing two different amounts of pressure against the pin/roller of the lifter...I would also guess the roller pin is made of some serouis material, and the outside of the lifter (broken piece) that holds the pin in place would be the "weak link" here....the lifter could/would collaspe till it bottoms out and acts as a solid lifter, then there is no "give".

It's possible, might be a stretch, but possible.. I agree, probably a bad lifter, but given those Ford lifters are used in some serouis motors, it's rare to see them fail the way this one did.....Could be some other unkown "thing" contributed to the lifters failure. I wonder what the camshaft lobe looked like????

David

|

You make a good point. With the ramp rate of the lobe, the force vector on the pin would not be straight up. Therefore if the pin were to flex it should be at some angle, so the break should not have been straight across.

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 11:18 PM.

Links monetized by VigLink

|