Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

|

1 |

| 2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 9 |

10 |

11 |

12 |

13 |

14 |

15 |

| 16 |

17 |

18 |

19 |

20 |

21 |

22 |

| 23 |

24 |

25 |

26 |

27 |

28 |

|

|

CC Advertisers

CC Advertisers

|

|

09-13-2011, 05:10 AM

|

|

CC Member

|

|

|

Join Date: Apr 2011

Posts: 1,092

|

|

Not Ranked

Not Ranked

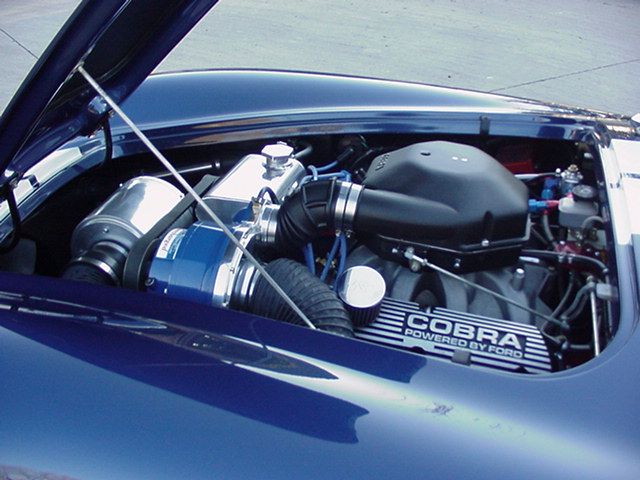

Paxton Superchargers

Paxton Superchargers

Paxton states the optimum CR for their small block ford superchargers is 9.0:1 (like with using the NOVI 1500). Just curious, anyone using a Paxton designed for a stroked 351W (near 427 CID) and with a CR higher than than 9:1, like maybe 10.5:1? If so, how do you like it and did you have any issues with the higher CR? This would be my plan 'B' if I decide to boost and not go the turbocharger rout. My CR is 10.4:1 on a high quality DART 427W build.

|

09-13-2011, 06:07 AM

|

|

CC Member

|

|

|

Join Date: Apr 2008

Location: Glastonbury,

Ct

Cobra Make, Engine: ERA2041 sold 2021

Posts: 241

|

|

Not Ranked

Not Ranked

I installed a Paxton on my '66 Shelby GT350 mustang, which had 10:1 compression. The Holley carb had to be rejetted slightly richer, and replaced the brass floats with (nitrofill ?) plastic ones to prevent them from collapsing under boost. I had severe pinging on acceleration, and had to add a ping sensor and electronic spark retard box (made by Carter, I think) which retarded the spark up to 15 degrees when pinging was sensed. The boost was only about 5 1/2 psi, but the car was very strong. I always felt I was giving up horsepower by retarding the spark, but didn't want to tear the engine apart to lower the compression. If I had it to do over again, I would build the motor with lower compression, or just stay naturally aspirated. Good luck

|

09-13-2011, 06:52 AM

|

|

CC Member

|

|

|

Join Date: Apr 2011

Posts: 1,092

|

|

Not Ranked

Not Ranked

Good input, I actually would rather not go forced air if I don't have to. It all boils down to what RWHP I get when all is done. I'm looking for 450 or better at the wheels, if I come in at 400 or less I will probably do something. It'll probably dyno in-between so I'll just have to drive it and see if that will be enough for the cheap thrills. I've got a BMW K1200S sportbike (175hp/530lbs), pretty close to a human cannonball experience - if get anywhere near that I'll be quite happy

---- |

09-13-2011, 07:47 AM

|

|

CC Member

|

|

|

Join Date: Feb 2005

Location: Perrysburg,

OH

Cobra Make, Engine: SPF #298 427 FI

Posts: 497

|

|

Not Ranked

Not Ranked

Most of my experience in the supercharger area is in the FI arena. I do know that the vets are 10.5 compression and seem to get away with it. That being said they are FI and the ecu makes the necessary adjustments. Have you considered going with a twin screw type like a kenne bell or whipple?

|

09-13-2011, 09:05 AM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: St. Louisville,

Oh

Cobra Make, Engine: A&C 67 427 cobra SB

Posts: 2,445

|

|

Not Ranked

Not Ranked

You need to back timing off as boost goes up. If you quit thinking in terms of vacuum advance and manifold pressure (boost) and start thinking in terms of absolute pressure, then it makes more sense. The lower the Manifold Absolute Pressure (MAP) the more timing you need and conversely the higher the MAP the less timing you need.

The way to run boost on a high compression ratio engine is to cool the air back down, to ambient temp, before it goes into the intake manifold. Compression of air heats it. Superchargers compress air. In addition to the heat of compression, inefficiency of the blower adds heat. It the case of the turbo, exhaust heat conducts into the air charge, as well. An after-cooler is the solution.

If the air temp is too high, the fuel/air charge will auto-ignite on the compression stroke before the ignition spark, called pre-detonation. When this occurs, you may not be able to get off the throttle quick enough to save the engine.

Last edited by olddog; 09-13-2011 at 09:11 AM..

|

09-13-2011, 01:39 PM

|

|

CC Member

|

|

|

Join Date: Feb 2007

Location: Colorado Springs,

CO

Cobra Make, Engine: Backdraft, supercharged Coyote

Posts: 2,452

|

|

Not Ranked

Not Ranked

The big issue - as stated above - is detonation. Detonation can quickly destroy an engine, is primarily caused by excessive cylinder pressure.

Static compression ratio is only part of the equation. What you're really interested in is dynamic compression ratio; which is a function of static compression, ambient air pressure, altitude, and intake valve closing points. There's a few other data bits, but these are the major ones. You can easily build an engine with 10.0 static compression, and a dynamic compression of 9.0 - which is way too high for pump gas. Or you could build it with a DCR of 7.8 - which is really good for pump gas. So, before building your stroker, do the math and figure out what your max DCR + boost will be.

Along with pressure, heat will really accelerate detonation. You can keep the intake charge cooler by running a little rich, intercoolers, and water/methanol injection. Keeping the timing very conservative also helps.

__________________

.boB "Iron Man"

NASA Rocky Mountain TTU #42

www.RacingtheExocet.com

BDR #1642 - Supercharged Coyote, 6 speed Auto

|

09-13-2011, 02:18 PM

|

|

CC Member

|

|

|

Join Date: Jul 2008

Cobra Make, Engine: SPF #2899 Dart 440 stroker 771 hp w/nitrous

Posts: 69

|

|

Not Ranked

Not Ranked

Just a thought...I have a comparable motor - 604.8 @7000 531@4500 torque. I added a 150 shot! It's easy and trouble free....so far!

|

09-13-2011, 03:53 PM

|

|

CC Member

|

|

|

Join Date: Apr 2011

Posts: 1,092

|

|

Not Ranked

Not Ranked

ECS does vettes all the time with the Paxton, but as stated - in the EFI configuration. I'll give them a call and see what tricks they have up their sleeve. Looked at the Keene Bell and Whipple twin screws, pretty slick. Between the two is there a preferred manufacturer? Both looked like high quality units - seems like Whipple a little better in the customer service department.

|

09-13-2011, 07:58 PM

|

|

CC Member

|

|

|

Join Date: Oct 1999

Location: Prosper,

TX

Cobra Make, Engine: CAV GT40 #169, Ford 408 Stroker & ZF Transaxle

Posts: 2,408

|

|

Not Ranked

Not Ranked

I did an original Paxton with 750 holley (huge jets) in the bonnett on a Superformance Cobra 351 that had 9.8 compression back in 2001. I used the MSD retard ignition box that retarded the timing under acceleration and also use a fuel pressure regulator that increase the fuel pressure as the Paxton made boost. The Paxton was rebuilt with a bigger disc inside for the 351 as the orignial only put out about 4 or 5 lbs of boost and this one took it up to 10 or 12. Was a pretty cool car back then....Sold it to a guy in Nashville and saw it on Ebay a couple years ago.

__________________

Gary

CAV GT40

Last edited by gsharapa; 09-13-2011 at 08:02 PM..

|

09-13-2011, 08:42 PM

|

|

CC Member

|

|

|

Join Date: Aug 2007

Location: NE Oklahoma,

OK

Cobra Make, Engine: Fords

Posts: 544

|

|

Not Ranked

Not Ranked

Stock timing on my Hi-Po 289 engine is 40 degrees BTDC, stock compression is 10.0:1. With the vintage Paxton I've found it necessary to reduce the timing by just 7 degrees to 33 BTDC to eliminate detonation. In the winter, or when the airt temp is under 70 degrees, I can get by with 36 total timing advance.

Z.

__________________

'65 K code Mustang

'66 Galaxie 500

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 07:01 PM.

Links monetized by VigLink

|