Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| 1 |

2 |

3 |

4 |

5 |

6 |

7 |

| 8 |

9 |

10 |

11 |

12 |

13 |

14 |

| 15 |

16 |

17 |

18 |

19 |

20 |

21 |

| 22 |

23 |

24 |

25 |

26 |

27 |

28 |

| 29 |

30 |

31 |

|

|

|

|

|

CC Advertisers

CC Advertisers

|

|

7Likes 7Likes

11-14-2015, 03:19 PM

|

|

CC Member

|

|

|

Join Date: Sep 2013

Location: Memphis,

TN

Cobra Make, Engine: SPF#1867 , KC427

Posts: 431

|

|

Not Ranked

Not Ranked

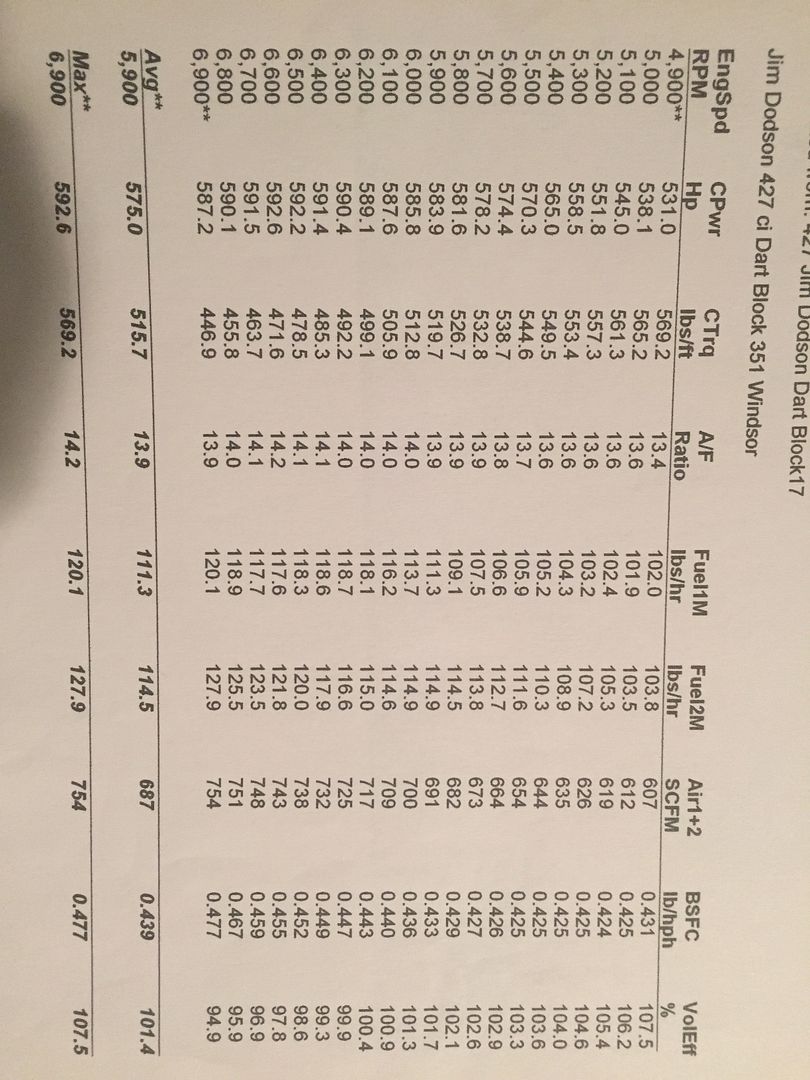

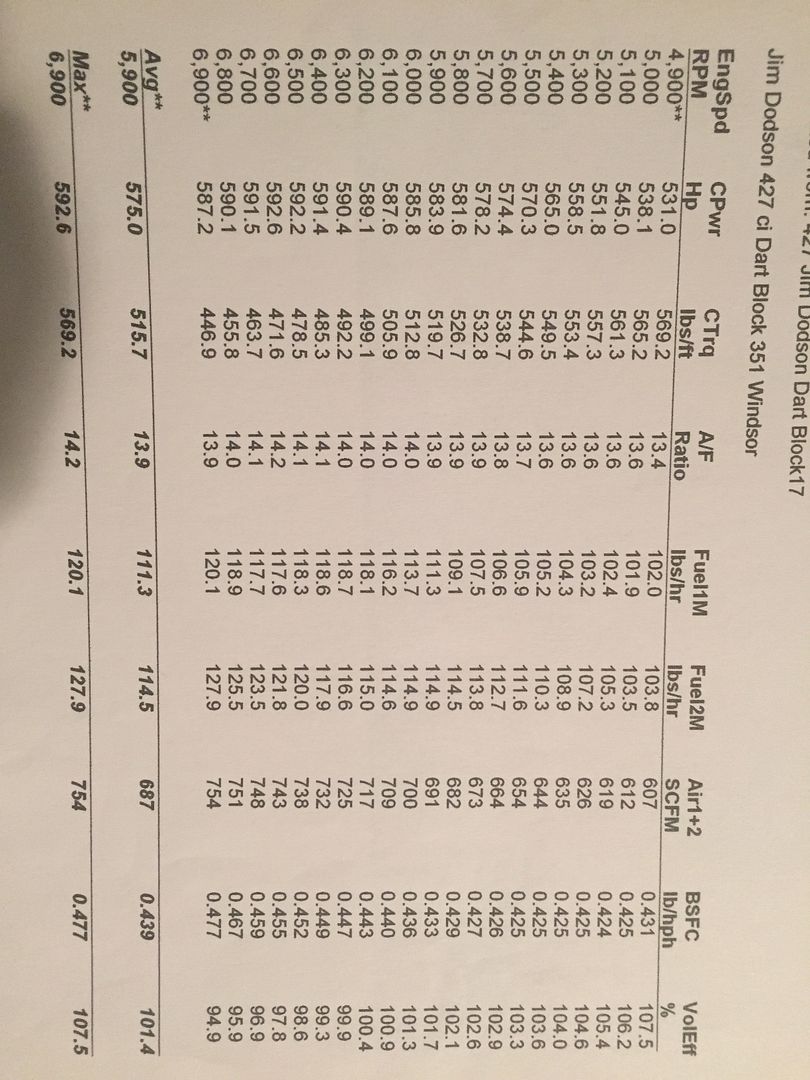

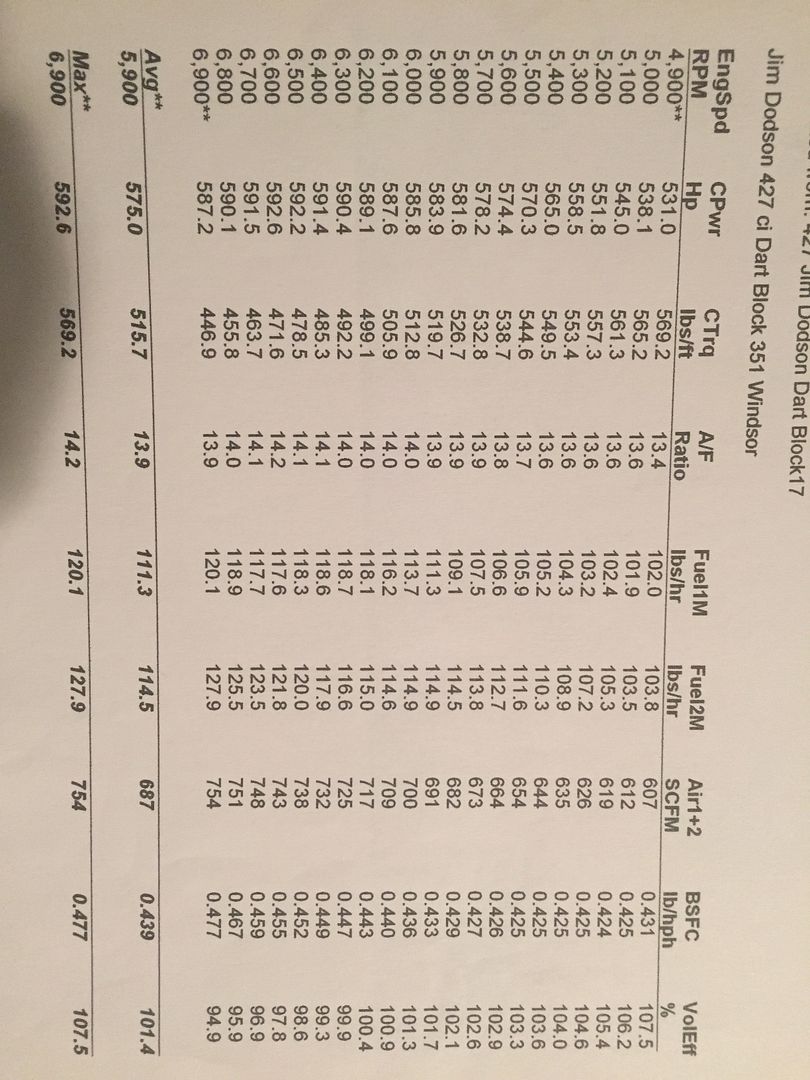

So while the WWF cage match of the 427 Windsor vs 427 FE is brewing I would like to better understand the following so I can understand the decisions I am making.

ALL QUESTIONS ARE BASED OFF A WINDSOR PLATFORM BETWEEN 427-460CI

*Edelbrock list the Performer RRM Air Gap for a RPM range of 1,500-6,500. Now with this being said I am sure that cam selection , cylinder heads and compression all play a major role. My question relates to a street car that lets say peaks at 5500-5800rpm leaving you shifting at 6000rpm. Why is the dual plane not the appropriate intake? Brent why did you build your 438W with the RPM air gap instead of the Victor Jr?

*2" primary header size. This has been a 50/50 answer that I've recieved. Why on a street car would you keep 2" headers? The only information I have come across that seems to have come from someone who actually had 2" headers was an old post on here were a guy had a Roush 427 and he stated that on the dyno the 2" made a few HP more but only on the very top end......while the bottom end was down 25-50 torque. Is the 2" header design only applicable for cars that would be tracked?. If a street car is setup for 6000rpm why would a 2" primary header size be appropriate.

Last edited by Ace23; 11-14-2015 at 03:39 PM..

|

11-14-2015, 04:26 PM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Ace23

So while the WWF cage match of the 427 Windsor vs 427 FE is brewing I would like to better understand the following so I can understand the decisions I am making.

ALL QUESTIONS ARE BASED OFF A WINDSOR PLATFORM BETWEEN 427-460CI

*Edelbrock list the Performer RRM Air Gap for a RPM range of 1,500-6,500. Now with this being said I am sure that cam selection , cylinder heads and compression all play a major role. My question relates to a street car that lets say peaks at 5500-5800rpm leaving you shifting at 6000rpm. Why is the dual plane not the appropriate intake? Brent why did you build your 438W with the RPM air gap instead of the Victor Jr?

*2" primary header size. This has been a 50/50 answer that I've recieved. Why on a street car would you keep 2" headers? The only information I have come across that seems to have come from someone who actually had 2" headers was an old post on here were a guy had a Roush 427 and he stated that on the dyno the 2" made a few HP more but only on the very top end......while the bottom end was down 25-50 torque. Is the 2" header design only applicable for cars that would be tracked?. If a street car is setup for 6000rpm why would a 2" primary header size be appropriate.

|

Well, some customers ask for intakes specifically, either because of hood clearance or other issues. I typically would not use a dual plane intake on such a large engine, even if it is a 6000 rpm engine.

As for Anthony's dyno results, I would be concerned about what differences there were between cars and years of dynoing....and the fact that the numbers don't match the graph, as they do with the roush engine....

Last edited by blykins; 11-14-2015 at 04:42 PM..

|

11-14-2015, 04:47 PM

|

|

CC Member

|

|

|

Join Date: Aug 2007

Location: Carlsbad,

Ca

Cobra Make, Engine: SPF 2932 with 438 Lykins Motorsports engine. Previous owner of FFR 5452.

Posts: 2,616

|

|

Not Ranked

Not Ranked

As an aside, I own that 438W that Brent built last year and I can attest to the fact that it is a sweet street engine. Pulls like a freight train from about 1800 rpm and will cruise all day at 2000 rpm if that's what you want. I like to keep it around 2600 rpm. Then it's real happy.

__________________

Jim

|

11-14-2015, 05:16 PM

|

|

CC Member

|

|

|

Join Date: Aug 2002

Location: Richmond,

VA

Cobra Make, Engine: Superformance Mk III / Windsor platform

Posts: 450

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Ace23

So while the WWF cage match of the 427 Windsor vs 427 FE is brewing I would like to better understand the following so I can understand the decisions I am making.

ALL QUESTIONS ARE BASED OFF A WINDSOR PLATFORM BETWEEN 427-460CI

*Edelbrock list the Performer RRM Air Gap for a RPM range of 1,500-6,500. Now with this being said I am sure that cam selection , cylinder heads and compression all play a major role. My question relates to a street car that lets say peaks at 5500-5800rpm leaving you shifting at 6000rpm. Why is the dual plane not the appropriate intake? Brent why did you build your 438W with the RPM air gap instead of the Victor Jr?

*2" primary header size. This has been a 50/50 answer that I've recieved. Why on a street car would you keep 2" headers? The only information I have come across that seems to have come from someone who actually had 2" headers was an old post on here were a guy had a Roush 427 and he stated that on the dyno the 2" made a few HP more but only on the very top end......while the bottom end was down 25-50 torque. Is the 2" header design only applicable for cars that would be tracked?. If a street car is setup for 6000rpm why would a 2" primary header size be appropriate.

|

I put 2" headers on my Roush 427R. (Dual plane intake with AED 750, 3" Stainless Specialties mufflers). They sounded and felt really good at the very top end for the last 1500 rpm or so, just before it hit the rev limiter@ 6400 rpm. Low end torque was way off. This was verified on the dyno, on the drag strip and daily street driving seat of the pants. Overall performance was better with the stock Superformance headers. I really wanted the bigger headers to be better. In my experience, they weren't. FWIW. Your mileage may vary, so to speak.

|

11-14-2015, 06:23 PM

|

|

CC Member

|

|

|

Join Date: Sep 2013

Location: Memphis,

TN

Cobra Make, Engine: SPF#1867 , KC427

Posts: 431

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by SPF1061

I put 2" headers on my Roush 427R. (Dual plane intake with AED 750, 3" Stainless Specialties mufflers). They sounded and felt really good at the very top end for the last 1500 rpm or so, just before it hit the rev limiter@ 6400 rpm. Low end torque was way off. This was verified on the dyno, on the drag strip and daily street driving seat of the pants. Overall performance was better with the stock Superformance headers. I really wanted the bigger headers to be better. In my experience, they weren't. FWIW. Your mileage may vary, so to speak.

|

Great info on the headers! I thought most Roush 427R's used a single plane intake. Did you change to a dual plane and if so which intake? If you thought the bottom end disappeared with the larger headers and dual plane then you can imagine how mine might feel with 2" and a single plane. My side pipes are currently 2-1/2" but I'm going to 3". We are very close to getting it buttoned back up for a test ride to see if the new fuel system solves the missing power issue.

|

11-14-2015, 06:33 PM

|

|

CC Member

|

|

|

Join Date: Sep 2013

Location: Memphis,

TN

Cobra Make, Engine: SPF#1867 , KC427

Posts: 431

|

|

Not Ranked

Not Ranked

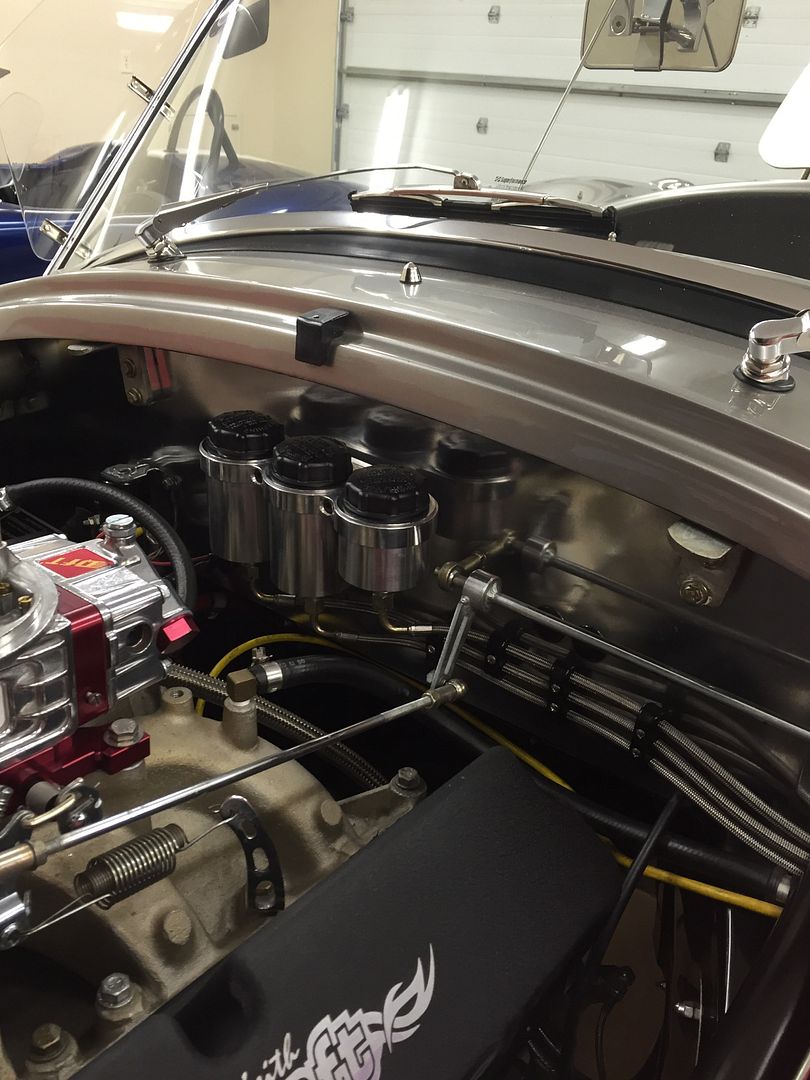

Construction Zone

Current 2" Headers

A few hours of elbow grease to put the shine on it. I've used White Diamond polish and I should have taken before pics.....was awful. You can see how the manifold is a real eye sore now. Do not worry the yellow oil pressure line is going black. I also want to take the vaccum line of the #8 cylinder and relocate it. I am going to get rid of the rubber line and go with a braided line.

|

11-15-2015, 10:50 AM

|

|

CC Member

|

|

|

Join Date: Apr 1999

Location: cleveland,

OH

Cobra Make, Engine: CSX4000, 427

Posts: 1,999

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by twin turbo

That's strange, all my dyno sheets show my hp and torque crossing/equal at 5252 rpm.

|

Well, this graph also shows the torque and HP are the same at 5252.

The difference is that the Y axis on the HP and the Torque are not the same. You need to look at each side of the graph and its corresponding curve.

Are you able to see that?

__________________

"After jumping into an early lead, Miles pitted for no reason. He let the entire field go by before re-entering the race. The crowd was jumping up and down as he stunned the Chevrolet drivers by easily passing the entire field to finish second behind MacDonald's other team Cobra. The Corvette people were completely demoralized."

|

11-15-2015, 10:59 AM

|

|

CC Member

|

|

|

Join Date: Apr 1999

Location: cleveland,

OH

Cobra Make, Engine: CSX4000, 427

Posts: 1,999

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Ace23

So while the WWF cage match of the 427 Windsor vs 427 FE is brewing I would like to better understand the following so I can understand the decisions I am making.

|

My post was directed that you can still make a lot of power with a dual plane intake.

And as an caveat, a "1964 Ford crate 427 Hi-Riser dual plane intake engine" made a lot of horsepower, even though many consider that it was at a disadvantage being that it was FE design coupled with a dual plane intake, and it performed as well, or even better than a much more state of the art crate 427 windsor.

So, I think if you get a good dual plane, as compared to a single plane, there may not be as much of a difference in HP as you may think.

I didn;t build my FE 427 with any HP figures as a target, or was intially comparing it to any other engine. I wanted to replicate a 427 FE that one could purchase from Ford at that time the 427 cobra's were being built. The HP output is what it is, and it surprised me to some degree. If it was lower, I still would have been equally satisfied, as the HP figure was really not that important to me, only to get it dyno tuned to the best it could be.

__________________

"After jumping into an early lead, Miles pitted for no reason. He let the entire field go by before re-entering the race. The crowd was jumping up and down as he stunned the Chevrolet drivers by easily passing the entire field to finish second behind MacDonald's other team Cobra. The Corvette people were completely demoralized."

|

11-15-2015, 11:39 AM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

Anthony, any port work done? Which cam did you use?

|

11-15-2015, 02:47 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Mar 2005

Location: Manchester,

NH

Cobra Make, Engine: AK1085 (302 Street), HTM111 (427 Comp), CSX2375R (289 Comp) and COB5999 (427 S/C)

Posts: 19,011

|

|

Not Ranked

Not Ranked

Webers............��

|

11-15-2015, 03:23 PM

|

|

CC Member

|

|

|

Join Date: Aug 2002

Location: Richmond,

VA

Cobra Make, Engine: Superformance Mk III / Windsor platform

Posts: 450

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Ace23

Great info on the headers! I thought most Roush 427R's used a single plane intake. Did you change to a dual plane and if so which intake? If you thought the bottom end disappeared with the larger headers and dual plane then you can imagine how mine might feel with 2" and a single plane. My side pipes are currently 2-1/2" but I'm going to 3". We are very close to getting it buttoned back up for a test ride to see if the new fuel system solves the missing power issue.

|

I bought my Roush through Dennis Olthoff's shop. Dennis recommended the dual plane intake. It was shipped from Roush that way. I believe they use an Edelbrock Performer. It is a stout motor that has turned 11:30s/125mph at the strip on Avon's and is still very steerable. I just rolled over 75,000 miles on the odometer. 40,000+ miles of that on the Roush with a rebuild about 10,000 miles ago. |

11-15-2015, 08:51 PM

|

|

CC Member

|

|

|

Join Date: Sep 2013

Location: Memphis,

TN

Cobra Make, Engine: SPF#1867 , KC427

Posts: 431

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Anthony

My post was directed that you can still make a lot of power with a dual plane intake.

And as an caveat, a "1964 Ford crate 427 Hi-Riser dual plane intake engine" made a lot of horsepower, even though many consider that it was at a disadvantage being that it was FE design coupled with a dual plane intake, and it performed as well, or even better than a much more state of the art crate 427 windsor.

So, I think if you get a good dual plane, as compared to a single plane, there may not be as much of a difference in HP as you may think.

I didn;t build my FE 427 with any HP figures as a target, or was intially comparing it to any other engine. I wanted to replicate a 427 FE that one could purchase from Ford at that time the 427 cobra's were being built. The HP output is what it is, and it surprised me to some degree. If it was lower, I still would have been equally satisfied, as the HP figure was really not that important to me, only to get it dyno tuned to the best it could be.

|

Anthony,

I have no dog in the hunt. As long as your FE is making what you have been told and your happy then thats all that matters. I wouldn't know an FE if it fell on my head! I'm just a fortunate younger generation guy that is wading through the weeds of cobra ownership for the first time

|

11-21-2015, 07:53 PM

|

|

CC Member

|

|

|

Join Date: Sep 2013

Location: Memphis,

TN

Cobra Make, Engine: SPF#1867 , KC427

Posts: 431

|

|

Not Ranked

Not Ranked

The plan is to over time add a polished intake, air cleaner, and water pump in order to clean up the engine bay.

Polished the door hinges, wipers, windshield frame...basically anything that was a chrome or stainless part of the car.

Painted under the fenders with bedliner in order to strengthen the underside of the body and prevent a rock from spidering any of the paint

Last edited by Ace23; 11-21-2015 at 10:12 PM..

|

11-21-2015, 11:19 PM

|

|

CC Member

|

|

|

Join Date: Mar 2009

Cobra Make, Engine: FFR

Posts: 388

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Anthony

Well, this graph also shows the torque and HP are the same at 5252.

The difference is that the Y axis on the HP and the Torque are not the same. You need to look at each side of the graph and its corresponding curve.

Are you able to see that?

|

Ah, I see it now. Thanks for the clarification. |

11-22-2015, 11:02 PM

|

|

CC Member

|

|

|

Join Date: Sep 2013

Location: Memphis,

TN

Cobra Make, Engine: SPF#1867 , KC427

Posts: 431

|

|

Not Ranked

Not Ranked

We got the brakes bled and everthing back on the car and buttoned up. The brake fluid really needed changing.....it looked like jet black motor oil!. We fired up the car and checked for any oil and gas leaks but none were found. We allowed the engine oil and water temp to reach operating temperature and then we checked the timing. What we found was that the timing did not fully advance until about 3500-3700rpm. The distributor cap was checked and it was found to have two of the heavy silver springs. We changed one of the springs to a lighter tension spring allowing full advance in about 3000rpm. We did not make any timing adjustments as the timing was previously set when the car was dyno tuned leading to the low numbers which sent me down this path. We plan on taking the car out for a test ride tomorrow to see if any improvements is seen. I'm still not ruling out a cam change and leak down test but the car needed some general mainteance and I wanted to eliminate a few things off the list. Big thanks to PMAN1961 for all the help and teaching me the ropes on these cars!

Last edited by Ace23; 11-22-2015 at 11:15 PM..

|

11-23-2015, 03:01 AM

|

|

CC Member

|

|

|

Join Date: Jul 2009

Location: Westerly,

RI

Cobra Make, Engine: Fordstroker 408w custom solid roller-Craft ported Brodix 17*heads-CFM ported Vic Jr. intake-1 3/4 primaries- 575hp-TKO-600RR Liberty upgrade- -Moser 8.8 trutrac-McLeod Street Extreme--QA-1-Wilwood brakes, Classic Chambered 3" Cobrapacks, Avon's

Posts: 645

|

|

Not Ranked

Not Ranked

Sounds like you put a light silver in. Good move, go quicker and try two blue springs, light stick shift cars like the cobra respond well to this advance curve. Going in the right direction, good luck!

__________________

Lou

|

11-23-2015, 04:28 AM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

X2....

Most performance applications in general respond very well to a quick timing curve. I would set the total timing to be all in by about 2600-2800.

|

11-23-2015, 06:20 AM

|

|

CC Member

|

|

|

Join Date: Aug 2008

Location: Memphis,

TN

Cobra Make, Engine: Superformance SP02423 KCR 445W 611hp 599ft lbs

Posts: 321

|

|

Not Ranked

Not Ranked

You are welcome ACE!! Thanks for not telling all I crossed a pair of wires on the distributor cause a nice little pop at our first crank!! Brent I agree with the earlier full timing. Again, the Internet provides so much advice not all being the same which makes making decisions difficult. The tuner and an article I read recently recommended full timing at 3000 on this size stroker engine. We can swap some springs no problem to achieve the specs you are suggesting.

|

11-23-2015, 10:31 AM

|

|

CC Member

|

|

|

Join Date: Sep 2013

Location: Memphis,

TN

Cobra Make, Engine: SPF#1867 , KC427

Posts: 431

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by RET_COP

Sounds like you put a light silver in. Good move, go quicker and try two blue springs, light stick shift cars like the cobra respond well to this advance curve. Going in the right direction, good luck!

|

That is correct. The cap had 2 heavy silver springs and we changed one to the lighter silver spring. This resulted in full advance coming in at around 3000rpm compared to the previous 3500rpm. Thanks for the advice

Quote:

Originally Posted by blykins

X2....

Most performance applications in general respond very well to a quick timing curve. I would set the total timing to be all in by about 2600-2800.

|

As Perry noted we can change to the 2 blue springs and see where that gets us. I do have a question as I do not completely understand timing and what effects it can have. If we changed the springs and full timing comes in 2600-2800 what happens when you are cruising on the interstate at 2500-3000rpm? Is it a bad thing to be at a cruising speed with full advance? I do not want this to be about gas mileage but will I see any improvement if I am running the lighter springs and my timing is more advanced at a lower RPM state?

I did find this write up and just thought it was interesting.

TIMING AND VACUUM ADVANCE 101

The most important concept to understand is that lean mixtures, such as at idle and steady highway cruise, take longer to burn than rich mixtures; idle in particular, as idle mixture is affected by exhaust gas dilution. This requires that lean mixtures have "the fire lit" earlier in the compression cycle (spark timing advanced), allowing more burn time so that peak cylinder pressure is reached just after TDC for peak efficiency and reduced exhaust gas temperature (wasted combustion energy). Rich mixtures, on the other hand, burn faster than lean mixtures, so they need to have "the fire lit" later in the compression cycle (spark timing retarded slightly) so maximum cylinder pressure is still achieved at the same point after TDC as with the lean mixture, for maximum efficiency.

The centrifugal advance system in a distributor advances spark timing purely as a function of engine rpm (irrespective of engine load or operating conditions), with the amount of advance and the rate at which it comes in determined by the weights and springs on top of the autocam mechanism. The amount of advance added by the distributor, combined with initial static timing, is "total timing" (i.e., the 34-36 degrees at high rpm that most SBC's like). Vacuum advance has absolutely nothing to do with total timing or performance, as when the throttle is opened, manifold vacuum drops essentially to zero, and the vacuum advance drops out entirely; it has no part in the "total timing" equation.

At idle, the engine needs additional spark advance in order to fire that lean, diluted mixture earlier in order to develop maximum cylinder pressure at the proper point, so the vacuum advance can (connected to manifold vacuum, not "ported" vacuum - more on that aberration later) is activated by the high manifold vacuum, and adds about 15 degrees of spark advance, on top of the initial static timing setting (i.e., if your static timing is at 10 degrees, at idle it's actually around 25 degrees with the vacuum advance connected). The same thing occurs at steady-state highway cruise; the mixture is lean, takes longer to burn, the load on the engine is low, the manifold vacuum is high, so the vacuum advance is again deployed, and if you had a timing light set up so you could see the balancer as you were going down the highway, you'd see about 50 degrees advance (10 degrees initial, 20-25 degrees from the centrifugal advance, and 15 degrees from the vacuum advance) at steady-state cruise (it only takes about 40 horsepower to cruise at 50mph).

When you accelerate, the mixture is instantly enriched (by the accelerator pump, power valve, etc.), burns faster, doesn't need the additional spark advance, and when the throttle plates open, manifold vacuum drops, and the vacuum advance can returns to zero, retarding the spark timing back to what is provided by the initial static timing plus the centrifugal advance provided by the distributor at that engine rpm; the vacuum advance doesn't come back into play until you back off the gas and manifold vacuum increases again as you return to steady-state cruise, when the mixture again becomes lean.

The key difference is that centrifugal advance (in the distributor autocam via weights and springs) is purely rpm-sensitive; nothing changes it except changes in rpm. Vacuum advance, on the other hand, responds to engine load and rapidly-changing operating conditions, providing the correct degree of spark advance at any point in time based on engine load, to deal with both lean and rich mixture conditions. By today's terms, this was a relatively crude mechanical system, but it did a good job of optimizing engine efficiency, throttle response, fuel economy, and idle cooling, with absolutely ZERO effect on wide-open throttle performance, as vacuum advance is inoperative under wide-open throttle conditions. In modern cars with computerized engine controllers, all those sensors and the controller change both mixture and spark timing 50 to 100 times per second, and we don't even HAVE a distributor any more - it's all electronic.

Now, to the widely-misunderstood manifold-vs.-ported vacuum aberration. After 30-40 years of controlling vacuum advance with full manifold vacuum, along came emissions requirements, years before catalytic converter technology had been developed, and all manner of crude band-aid systems were developed to try and reduce hydrocarbons and oxides of nitrogen in the exhaust stream. One of these band-aids was "ported spark", which moved the vacuum pickup orifice in the carburetor venturi from below the throttle plate (where it was exposed to full manifold vacuum at idle) to above the throttle plate, where it saw no manifold vacuum at all at idle. This meant the vacuum advance was inoperative at idle (retarding spark timing from its optimum value), and these applications also had VERY low initial static timing (usually 4 degrees or less, and some actually were set at 2 degrees AFTER TDC). This was done in order to increase exhaust gas temperature (due to "lighting the fire late") to improve the effectiveness of the "afterburning" of hydrocarbons by the air injected into the exhaust manifolds by the A.I.R. system; as a result, these engines ran like crap, and an enormous amount of wasted heat energy was transferred through the exhaust port walls into the coolant, causing them to run hot at idle - cylinder pressure fell off, engine temperatures went up, combustion efficiency went down the drain, and fuel economy went down with it.

If you look at the centrifugal advance calibrations for these "ported spark, late-timed" engines, you'll see that instead of having 20 degrees of advance, they had up to 34 degrees of advance in the distributor, in order to get back to the 34-36 degrees "total timing" at high rpm wide-open throttle to get some of the performance back. The vacuum advance still worked at steady-state highway cruise (lean mixture = low emissions), but it was inoperative at idle, which caused all manner of problems - "ported vacuum" was strictly an early, pre-converter crude emissions strategy, and nothing more.

What about the Harry high-school non-vacuum advance polished billet "whizbang" distributors you see in the Summit and Jeg's catalogs? They're JUNK on a street-driven car, but some people keep buying them because they're "race car" parts, so they must be "good for my car" - they're NOT. "Race cars" run at wide-open throttle, rich mixture, full load, and high rpm all the time, so they don't need a system (vacuum advance) to deal with the full range of driving conditions encountered in street operation. Anyone driving a street-driven car without manifold-connected vacuum advance is sacrificing idle cooling, throttle response, engine efficiency, and fuel economy, probably because they don't understand what vacuum advance is, how it works, and what it's for - there are lots of long-time experienced "mechanics" who don't understand the principles and operation of vacuum advance either, so they're not alone.

Vacuum advance calibrations are different between stock engines and modified engines, especially if you have a lot of cam and have relatively low manifold vacuum at idle. Most stock vacuum advance cans aren’t fully-deployed until they see about 15” Hg. Manifold vacuum, so those cans don’t work very well on a modified engine; with less than 15” Hg. at a rough idle, the stock can will “dither” in and out in response to the rapidly-changing manifold vacuum, constantly varying the amount of vacuum advance, which creates an unstable idle. Modified engines with more cam that generate less than 15” Hg. of vacuum at idle need a vacuum advance can that’s fully-deployed at least 1”, preferably 2” of vacuum less than idle vacuum level so idle advance is solid and stable; the Echlin #VC-1810 advance can (about $10 at NAPA) provides the same amount of advance as the stock can (15 degrees), but is fully-deployed at only 8” of vacuum, so there is no variation in idle timing even with a stout cam.

For peak engine performance, driveability, idle cooling and efficiency in a street-driven car, you need vacuum advance, connected to full manifold vacuum. Absolutely. Positively. Don't ask Summit or Jeg's about it – they don’t understand it, they're on commission, and they want to sell "race car" parts.

Last edited by Ace23; 11-23-2015 at 10:38 AM..

|

11-23-2015, 10:35 AM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

Not bad at all. In fact, it's better...

Think about guys running vac advance, which gives an additional amount of advance to the mechanical. At cruising rpm/speed, these guys are seeing WAY more than what you would see.

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 06:34 AM.

Links monetized by VigLink

|