Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

|

1 |

| 2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 9 |

10 |

11 |

12 |

13 |

14 |

15 |

| 16 |

17 |

18 |

19 |

20 |

21 |

22 |

| 23 |

24 |

25 |

26 |

27 |

28 |

29 |

| 30 |

31 |

|

|

|

|

|

|

CC Advertisers

CC Advertisers

|

|

06-05-2017, 02:48 PM

|

|

CC Member

|

|

|

Join Date: Nov 2014

Location: Lipan,

TX

Cobra Make, Engine: Superformance MK III Roadster, Roush 402

Posts: 57

|

|

Not Ranked

Not Ranked

#5 piston, showing impacts |

06-05-2017, 09:27 PM

|

|

CC Member

|

|

|

Join Date: May 2008

Location: Brisbane,

QLD

Cobra Make, Engine:

Posts: 2,797

|

|

Not Ranked

Not Ranked

Are the pistons in the right way? The valve has hit the other side, not the valve relief side?

So now some more head repairs, including some better guides, and a smaller diameter retainer etc, and checking all clearances at dummy assembly.

Light checking springs etc for rocker geometry, to get pushrod length correct.

Maybe your pushrods were too short to start with?

Gary

|

06-06-2017, 02:02 AM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Gilroy,

CA

Cobra Make, Engine: SPF 2291, Whipple Blown & Injected 4V ModMotor

Posts: 2,738

|

|

Not Ranked

Not Ranked

From the pic in post #21 your valve reliefs are on the wrong side of the bore, like Gary suggested. It appears that someone unfamiliar with proper engine building practices simply assembled your engine without much care and certainly without inspection.

This is a relatively common mistake for a novice engine builder. Another relatively common mistake is to get pin offsets backwards because the builder is not paying attention or more likely doesn't understand. With your pistons in backwards, as they are, if you used offset pins it is highly probable they have found their way to the wrong holes also.

The rocker arms should never hit the retainers. The rocker manufacturers have been making these things for the better part of a half century. All the discovery in the manufacture of properly dimensioned rockers has been discovered a long time ago. If the engine's rocker geometry is not properly set up with correct pushrod length a short pushrod will lower the pushrod side of the rocker on its fulcrum allowing the kind of rocker to retainer interference you have experienced.

Another facet of the valvetrain set up is proper positioning of the rocker roller on the tip of the valve stem. A rocker with properly established geometry will wipe the tip of the roller from just short of the valve stem center to the valve stem center at max lift and then back again to its seated or resting position.

Another approach starts the rocker contact patch just short of center on the valve stem, wipes across the center of the valve stem at mid lift and reaches the geometrically similar position as the original starting point but on the opposite side of the valve stem at max lift. As the valve closes the rocker contact patch reverses its path to again return to the as seated condition it started from.

Different builders have different preferences. My personal preference for a pushrod engine is the first example.

To do these various things during the build process is not difficult but does require you to actually exert the effort to do the job. It appears whoever the engine builder these sorts of considerations were not a consideration.

This repair journey you are about to embark on will require a disassembly, repair of damaged components and correct reassembly of the all components. Engine builders who make these sorts of mistakes also do things like forget to balance the rotating assembly, balance it wrong, assemble the wrong piston to the wrong connecting rod and then get it on the wrong rod journal.

As if that is not enough, you can also bet that whoever overlooked which hole and which way the pistons should be fitted to the block also overlooked or incorrectly phased your cam to the crank. You are basically looking at a complete reassembly of the engine in the correct fashion rather than how you currently have it.

Bitter pill, I know but it is the right thing to do. There is no telling what additional 'special gifts' you are going to find.

Ed

__________________

Help them do what they would have done if they had known what they could do.

Help them do what they would have done if they had known what they could do.

|

06-06-2017, 11:11 AM

|

|

CC Member

|

|

|

Join Date: Oct 2000

Location: Crystal Lake,

IL

Cobra Make, Engine: Everett-Morrison, 434 cid

Posts: 977

|

|

Not Ranked

Not Ranked

When the valve dropped it made contact with the piston lower in the bore. That's why you're seeing contact in that area of the piston. The reliefs should be on the valley side of the piston.

|

06-06-2017, 01:53 PM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Gilroy,

CA

Cobra Make, Engine: SPF 2291, Whipple Blown & Injected 4V ModMotor

Posts: 2,738

|

|

Not Ranked

Not Ranked

Your are right Scott. That is why the piston is in backwards. The reliefs are on the exhaust side not the valley side. Look at where the block's locating dowel is for the head. It is in the lower left of the pic. That dowel and the reliefs should be both on the valley side of the block. The dowel is, the reliefs are not. This is a screw up plain and simple. Gary nailed it in post #22. Probability is this is not the only whoops in the build.

Ed

__________________

Help them do what they would have done if they had known what they could do.

Help them do what they would have done if they had known what they could do.

|

06-06-2017, 02:28 PM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Gore. New Zealand.,

SI

Cobra Make, Engine: DIY Coupe, F/T ,MkIV.

Posts: 808

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by eschaider

Your are right Scott. That is why the piston is in backwards. The reliefs are on the exhaust side not the valley side. Look at where the block's locating dowel is for the head. It is in the lower left of the pic. That dowel and the reliefs should be both on the valley side of the block. The dowel is, the reliefs are not. This is a screw up plain and simple. Gary nailed it in post #22. Probability is this is not the only whoops in the build.

Ed

|

WRONG, the dowels are on the outer side of block and valve reliefs toward valley, thats the way they are on all windsor blocks ( plus every other Ford pushrod V8 I can think off ), the out of position valve to piston contact marks are due to the bends in the valve stem as per pics. Piston is correct. Whole problem is due to rocker contact with valve retainer.

If its hyd cam lifter preload may have been set too deep or the valvetrain components have not been correct at initial build to arrive at the train wreck we are looking at now.

__________________

Jac Mac

|

06-06-2017, 03:49 PM

|

|

CC Member

|

|

|

Join Date: Feb 2014

Location: White City,

SK

Cobra Make, Engine: West Coast, 460 CID

Posts: 2,915

|

|

Not Ranked

Not Ranked

I wouldn't run aluminum retainers unless it was an engine with frequent planned teardowns.

Titanium retainers have replaced aluminum as the preferred alternative for those seeking lighter weight. Aluminum has pretty much disappeared from the market - with good reason.

__________________

Brian

|

06-06-2017, 04:02 PM

|

|

CC Member

|

|

|

Join Date: May 2008

Location: Brisbane,

QLD

Cobra Make, Engine:

Posts: 2,797

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Jac Mac

WRONG, the dowels are on the outer side of block and valve reliefs toward valley, thats the way they are on all windsor blocks ( plus every other Ford pushrod V8 I can think off ), the out of position valve to piston contact marks are due to the bends in the valve stem as per pics. Piston is correct. Whole problem is due to rocker contact with valve retainer.

If its hyd cam lifter preload may have been set too deep or the valvetrain components have not been correct at initial build to arrive at the train wreck we are looking at now.

|

I concur, the pistons are fitted correctly.

The builder should be aware of every necessary clearance during dummy and final assembly.

Quote:

Originally Posted by cycleguy55

I wouldn't run aluminum retainers unless it was an engine with frequent planned teardowns.

Titanium retainers have replaced aluminum as the preferred alternative for those seeking lighter weight. Aluminum has pretty much disappeared from the market - with good reason.

|

Fully agree.

|

06-06-2017, 06:50 PM

|

|

CC Member

|

|

|

Join Date: Mar 2006

Location: San Marcos california,

CA

Cobra Make, Engine: 1989 KCC from South Africa Right Hand Drive

Posts: 1,605

|

|

Not Ranked

Not Ranked

Ok...that was because the pushrods are too short .... If you have a floating rocker , IE with guide plates,. Do you have solid or hydraulic lifters?

Last edited by CHANMADD; 06-06-2017 at 06:54 PM..

|

06-06-2017, 07:45 PM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Gore. New Zealand.,

SI

Cobra Make, Engine: DIY Coupe, F/T ,MkIV.

Posts: 808

|

|

Not Ranked

Not Ranked

402R is hyd roller cam, so possibly just a case of the posi locs being turned down ~ say 1 turn or more rather than setting all at minimal lifter pre-load, this creates a situation like fitting short pushrods which can lead to rocker contact with retainer.

__________________

Jac Mac

|

06-06-2017, 09:34 PM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Gilroy,

CA

Cobra Make, Engine: SPF 2291, Whipple Blown & Injected 4V ModMotor

Posts: 2,738

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Jac Mac

WRONG, the dowels are on the outer side of block and valve reliefs toward valley, thats the way they are on all windsor blocks ( plus every other Ford pushrod V8 I can think off ), the out of position valve to piston contact marks are due to the bends in the valve stem as per pics. Piston is correct. Whole problem is due to rocker contact with valve retainer.

If its hyd cam lifter preload may have been set too deep or the valvetrain components have not been correct at initial build to arrive at the train wreck we are looking at now.

|

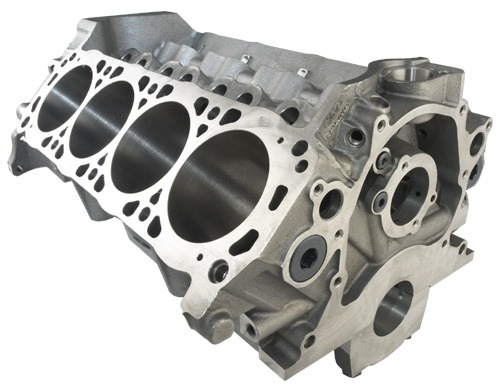

You are right Jac Mac, my bad. I was thinking of my Modmotor block and transferring its dowel placement to the Windsor family. For those with curious minds here is a pic of the Windsor block deck clearly showing the dowels on the exhaust side of the deck not the other way around.

Apologies for the misdirection guys.

Ed

__________________

Help them do what they would have done if they had known what they could do.

Help them do what they would have done if they had known what they could do.

|

10-17-2017, 12:01 PM

|

|

CC Member

|

|

|

Join Date: Feb 2012

Location: Keller,

TX

Cobra Make, Engine: Lonestar Classics LS427. Self-built 408W, AFR 195 heads, Performer RPM Intake, Quick Fuel 750, 407rwhp, 479rwtq

Posts: 549

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by cycleguy55

I wouldn't run aluminum retainers unless it was an engine with frequent planned teardowns.

Titanium retainers have replaced aluminum as the preferred alternative for those seeking lighter weight. Aluminum has pretty much disappeared from the market - with good reason.

|

Sorry to hijack the thread, but a question about retainers and locks...

I have the AFR Renegade 195 heads that come with the steel locks (part # 9007) but have chrome moly retainers (#8514). A suggested upgrade to these retainers are the titanium ones (#8515). Since I don't spin the motor over 6000 rpm and have .600 lift, do I need the titanium retainers? I don't have the problems listed in this thread - I have the CompCams Ultra Magnum rockers that have tons of clearance.

FYI - the springs are the AFR #8019 - 155# seat, 450# at 1.16, 0.650 max lift, 7200 max rpm.

Last edited by Texasdoc; 10-17-2017 at 12:08 PM..

|

10-20-2017, 05:03 AM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Virginia Beach, Va & Port Charlotte, Fl.,

Posts: 2,287

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Texasdoc

Sorry to hijack the thread, but a question about retainers and locks...

I have the AFR Renegade 195 heads that come with the steel locks (part # 9007) but have chrome moly retainers (#8514). A suggested upgrade to these retainers are the titanium ones (#8515). Since I don't spin the motor over 6000 rpm and have .600 lift, do I need the titanium retainers? I don't have the problems listed in this thread - I have the CompCams Ultra Magnum rockers that have tons of clearance.

FYI - the springs are the AFR #8019 - 155# seat, 450# at 1.16, 0.650 max lift, 7200 max rpm.

|

No, use your existing retainers. 7K RPM would drive me to TI retainers. Your locks are tool steel.

__________________

Too many toys?? never!

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 06:31 PM.

Links monetized by VigLink

|