Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

|

1 |

| 2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 9 |

10 |

11 |

12 |

13 |

14 |

15 |

| 16 |

17 |

18 |

19 |

20 |

21 |

22 |

| 23 |

24 |

25 |

26 |

27 |

28 |

|

|

CC Advertisers

CC Advertisers

|

|

09-06-2008, 09:40 PM

|

|

CC Member

|

|

|

Join Date: Aug 2006

Cobra Make, Engine: A&C

Posts: 379

|

|

Not Ranked

Not Ranked

800 CFM Four Barrel Street/Strip Carburetor

800 CFM Four Barrel Street/Strip Carburetor

Any Holley Guruís? 800 CFM Four Barrel Street/Strip Carburetor double pumper. Casting says 4780-4 3395 metering block 11398

I bought a used carb off ebay. I took it apart to rebuild it .. new gaskets Hp fast kit rebuild kit. Once I took it apart I discovered there is no power valve.  The casting on the metering block is block off. I've tried researching it and no information. How is this going to run? All I can guess is it more of a strip/ carb. I think the carb was modified with different metering blocks? Any thoughts. I plane on using it on a stroked 393 with performer manifold, aluminum heads (2.02 intakes), street/strip cam.

Ron |

09-06-2008, 10:22 PM

|

|

CC Member

|

|

|

Join Date: May 2008

Location: Brisbane,

QLD

Cobra Make, Engine:

Posts: 2,797

|

|

Not Ranked

Not Ranked

Ron,

Your 4780 is a 800 DP, has it got four corner idle circuit?

Does the primary metering block have a nipple for vacuum advance on your passenger side?

Are the metering blocks on backwards, primary on secondary side?

I've never heard of a "street carb" without a power valve, my listing for a 4780-4 shows a 6.5 power valve and 31 pump nozzles primary and secondary.

Hope this may help.

__________________

Gary

Gold Certified Holden Technician

|

09-06-2008, 10:28 PM

|

|

Beam Me Up Scottie

|

|

|

Join Date: Aug 2004

Location: Squantum (part of Quincy),

MA

Cobra Make, Engine: SPF1049 Titanium w/black stripes, 351W with Trick Flow Heads, Tremec 3550

Posts: 7,592

|

|

Not Ranked

Not Ranked

The main jets supplied from Holley on that carb were 71's but the secondaries were 85's. Since the secondaries are used under full power, and a big jet size, they really do not need a power valve in the secondaries. Many carbs from Holley have a secondary plate without a power valve, or a secondary metering block without a power valve.

The hole in the plate is not "blocked" off, rather, it was never machined for a power valve.

The power valve in the primary side does the power enrichment, along with the accelerator pumps helping during the transition to WOT.

I'm assuming there is a power valve on the primary metering block. If not, the previous owner removed it and installed a plug for some reason, or used a secondary metering block instead of the primary metering block, just to get the carb assembled for sale. That would be weird, and you might have some problem without a power valve. Maybe not. If this is the case, I would send an e-mail to the seller.

The primary metering block (supplied by Holley) would be number 134-229. The secondary metering block was number 134-230

The 3395 you mentioned is the date code ... carb was built in the 33rd week of 1995.

I have no idea what the 11398 number is for. All Holley metering blocks are numbered 134- with either 1 , 2 or 3 digits after the dash.

__________________

Warren

'Liberals are maggots upon the life of this planet and need to get off at the next rotation.' (Jamo 2008)

|

09-07-2008, 09:09 AM

|

|

CC Member

|

|

|

Join Date: Aug 2006

Cobra Make, Engine: A&C

Posts: 379

|

|

Not Ranked

Not Ranked

Thanks

Yes the power valve were never machine out. It has two idle circuit adjustment screws on the primary side. There are no 134's numbers on the metering blocks.

It has 80 jets on the primary side and 81's on the secondary.

Could I have the casting machined out for the power valve on the primary side? And go back to the smaller jets on that side (71).

Ron

|

09-07-2008, 09:46 AM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Bartlett,

Ill

Cobra Make, Engine: Everett-Morrison LS1

Posts: 2,448

|

|

Not Ranked

Not Ranked

just get the right metering plate and 6.5 pv

|

09-07-2008, 10:12 AM

|

|

Beam Me Up Scottie

|

|

|

Join Date: Aug 2004

Location: Squantum (part of Quincy),

MA

Cobra Make, Engine: SPF1049 Titanium w/black stripes, 351W with Trick Flow Heads, Tremec 3550

Posts: 7,592

|

|

Not Ranked

Not Ranked

No, you cannot machine out the metering block yourself.

It sounds like the previous owner swapped out the primary side metering block to one that does not use a power valve. Probably was only used for drag racing and it was easier to tune with just the jets. That's OK for a drag race only carb. But street operation without a power valve will suck big time!

Get the correct metering block and swap it out, and use a 65 PV like Jerry said and bring the jets back down to about 70 for initial starting point.

My strong suggestion is to also call Holley Tech.

Monday through Friday, 8AM to 5PM CST @ 270 781-9741.

They are very good and a lot of help. Have the carb in front of you when you call.

__________________

Warren

'Liberals are maggots upon the life of this planet and need to get off at the next rotation.' (Jamo 2008)

|

09-07-2008, 06:10 PM

|

|

CC Member

|

|

|

Join Date: Aug 2006

Cobra Make, Engine: A&C

Posts: 379

|

|

Not Ranked

Not Ranked

ok I'll do it.

|

09-08-2008, 12:55 PM

|

|

CC Member

|

|

|

Join Date: Aug 2006

Cobra Make, Engine: A&C

Posts: 379

|

|

Not Ranked

Not Ranked

Talk to Holley tech and they recommended getting the right metering block . They didn't have the part number on hand??

I went to summit and searched and came up with HLY-34R11196AQ. The orginal jets where 71 and 85. Is that a good place to start? I might be a little big with 800cfm. Should I drop down on jet size or does that matter to get a proper mixture.

Ron

|

09-08-2008, 02:59 PM

|

|

Beam Me Up Scottie

|

|

|

Join Date: Aug 2004

Location: Squantum (part of Quincy),

MA

Cobra Make, Engine: SPF1049 Titanium w/black stripes, 351W with Trick Flow Heads, Tremec 3550

Posts: 7,592

|

|

Not Ranked

Not Ranked

Ron

I looked at that Summit part and it looks like the right one. You want to use the new one in place of the one with idle screws and no provision for power valve. I'd leave the 71's in the primaries, unless you have any smaller ones (65 - 68's maybe). I assume you have not started the engine yet and need to break it in. I'd also install a 65 power valve.

If you have not run the motor yet, I would not go full throttle until at least 30 minutes at about 2800 - 3000 RPM to break in the cam, unless you have instructions for a different type of break in period.

I would also put in some smaller jets (around 74 to 76) in the secondaries during initial start up. You do not want to be too rich on initial start up.

The 800 cfm carb is a little big for your cubes, but it will work.

Good Luck

__________________

Warren

'Liberals are maggots upon the life of this planet and need to get off at the next rotation.' (Jamo 2008)

|

09-08-2008, 03:22 PM

|

|

CC Member

|

|

|

Join Date: Aug 2006

Cobra Make, Engine: A&C

Posts: 379

|

|

Not Ranked

Not Ranked

thanks warren

yep new engine. good advice on the jets 65's-74's. I also bought a the holley jet kit 39-99's so I change them around.

What I've read on flat hydraulic lifters if you need zinc and a 30 minute 3000 rpm break in. I'm hoping to get this right and not cranking to long on initial start up. I don't want to flatten the cam.

Ron

Last edited by rdc767; 09-08-2008 at 03:29 PM..

Reason: update

|

09-17-2008, 04:33 PM

|

|

CC Member

|

|

|

Join Date: Aug 2006

Cobra Make, Engine: A&C

Posts: 379

|

|

Not Ranked

Not Ranked

.Alright I got the new primary metering block with the power valve hole. I used the 6.5 vacuum valve.

It went together well. I used 68 jets in the primary and 76 in the secondarys.

I have a question on the accelerator pumps. I have the cam set to squirt the primary pump as soon as the throttle opens. This works well. And the cam and arm don't bottom out the primary pump.

Should the secondary pump start to squirt as the secondarys open? If it does…..

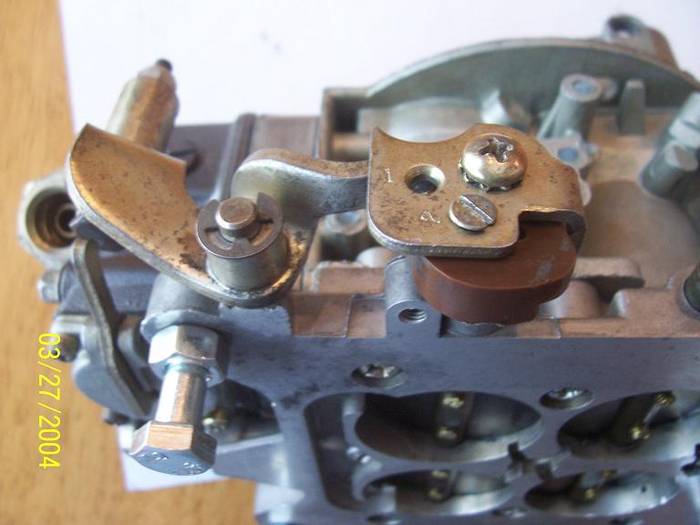

I cannot seem to figure out on how to set the cam on the secondary accelerator pump to start as they secondary butterfly valves open and not bottom out the accelerator pump   Secondary Side

Secondary Side

Primary side upside down

Primary side upside down

|

09-17-2008, 10:33 PM

|

|

Beam Me Up Scottie

|

|

|

Join Date: Aug 2004

Location: Squantum (part of Quincy),

MA

Cobra Make, Engine: SPF1049 Titanium w/black stripes, 351W with Trick Flow Heads, Tremec 3550

Posts: 7,592

|

|

Not Ranked

Not Ranked

Are both acc pumps the standard 30 cc variety? It looks like that in the picture. The thickness of the pump housing should be the same on both acc pumps. If a 50 cc pump was used, it needs different hardware as compared to the 30 cc pump.

But you might have 50 cc Reo pumps on both bowls. The pictures are not clear enough. Check the thickness of both housings and make sure they are the same.

The pump cam looks like its brown. The brown and yellow cam (if my memory is correct) are only used on a 50 cc pump and should not be used on a 30 cc pump.

Is that a white pump cam (stamped 218) on the primary side?

The Holley way to adjust is to open the throttle all the way (WOT). Push the pump arm lever down and then adjust the pump override spring to obtain .015" clearance between the pump arm and lever.

I like to take 2 wrenches on the pump override spring, and back off the nut until there is clearance (free play) between screw head and the pump arm. Then tighten until the free play is removed. Then go to WOT and check to see if you have clearance (at least .015 ").

Last but not least. Its been a long time since I looked at an acc pump cam from below like your picture. Is that brown cam installed correctly? It looks like it might be ass backwards? Can you install a pump cam incorrectly? Its been a long time since I changed one.

Good Luck - if the above does not help, send me a PM with your tel # and we can talk about it.

You might want to set the date on your camera.

__________________

Warren

'Liberals are maggots upon the life of this planet and need to get off at the next rotation.' (Jamo 2008)

Last edited by wtm442; 09-17-2008 at 10:35 PM..

|

09-18-2008, 04:05 PM

|

|

CC Member

|

|

|

Join Date: Aug 2006

Cobra Make, Engine: A&C

Posts: 379

|

|

Not Ranked

Not Ranked

The rebuild kit came with 4 new diaphams for the pump. 2 big (50cc) and 2 smaller ones. The small ones match the old ones.

The secondary cam is brown. That makes sense it would be for a 50cc. The ramp up is too great. If I use the 1 hole it binds the accelerator pump before I can go to wot.

I'll buy a cam kit for the carb and go from there. Thanks a ton.

Ron

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 10:58 PM.

Links monetized by VigLink

|