Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

|

1 |

| 2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 9 |

10 |

11 |

12 |

13 |

14 |

15 |

| 16 |

17 |

18 |

19 |

20 |

21 |

22 |

| 23 |

24 |

25 |

26 |

27 |

28 |

|

|

CC Advertisers

CC Advertisers

|

|

02-01-2010, 08:11 AM

|

|

CC Member

|

|

|

Join Date: Aug 2007

Location: Carlsbad,

Ca

Cobra Make, Engine: SPF 2932 with 438 Lykins Motorsports engine. Previous owner of FFR 5452.

Posts: 2,616

|

|

Not Ranked

Not Ranked

SPF Slave Cylinder Help.

SPF Slave Cylinder Help.

OK, I've adjusted and bled the system to no avail.

The clutch is just barely dragging when the pedal is fully depressed. Causing tough shifting into first and lots of noise in reverse. Another 1/4 of an inch of travel by the slave cylinder is all that is needed. And Yes, I have already adjusted the rod from the pedal to the M/C. Both cylinders are moving the full length of their travel. Both are 7/8 inch units.

I have the slave with no adjusting nuts on the shaft that comes out of the slave. It just has a bulb on the head and that rests against a depression in the clutch fork. Thus, no external adjusting of the rod is possible. Is there any way to put a shim between the fork and the rod or to put a spacer between the rod and the piston in the the slave to gain additional length? Or, can I replace the rod with another type that is threaded so I can have some sort of adjustment?

Finally, If I replace the slave with a similar unit, how do I keep all the brake fluid from running out of the M/C and the lines when I remove the line to the existing slave? All lines from the master to the slave are metal, so I can't clamp them. If I clamp the rubber line from the fluid reservoir to the M/C, will I then drain the M/C and have to bleed that too when I replace the slave?

Any other solutions you guys have come up with to this problem? The slave and M/C are both 7/8 inch, and the slave is travelling the full length of its stroke. It just isn't enough to fully depress the clutch.

And finally, the car has a Quiktime bell housing and a TKO600 trans with a pusher slave. Seems to be lined up OK with the shifting fork.

__________________

Jim

|

02-01-2010, 08:40 AM

|

|

CC Member / Sponsor

|

|

|

Join Date: Oct 2003

Cobra Make, Engine:

Posts: 808

|

|

Not Ranked

Not Ranked

JHV,

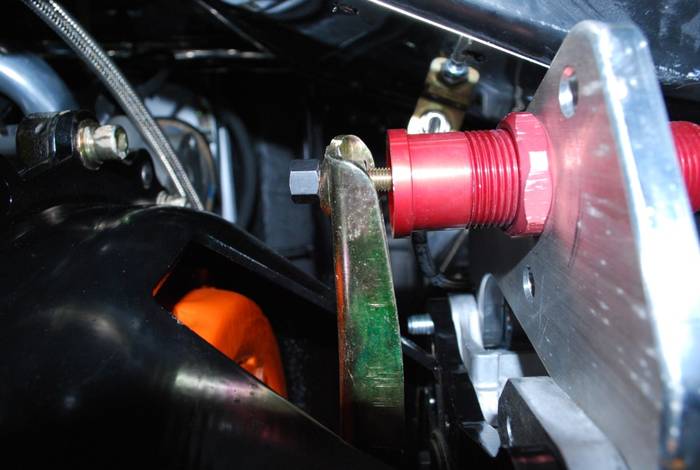

A couple of things you can try. First is to remove your non adjustable and install a threaded rod, 3/8 all thread grade 8. I would see if your clutch is slipping as well, your clutch maybe getting worn. Or you can buy one of my setups and it would work perfectly with your setup. Take a look. I removed the boot to show the rod position.

__________________

Squeaky wheel always gets the grease!!

www.gcperf.com

|

02-01-2010, 08:41 AM

|

|

CC Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine:

Posts: 3,077

|

|

Not Ranked

Not Ranked

to prevent the fluid from escaping put some saran wrap under the lid of your remote reservoir and screw back on.

I have a stock slave and it works perfect will plenty of travel. do you have the right slave cylinder???

|

02-01-2010, 08:48 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Oct 2006

Location: Santa Cruz,

CA

Cobra Make, Engine: SPF 2613 Titanium w/Black, Roush 402SR

Posts: 4,097

|

|

Not Ranked

Not Ranked

Jim,

How did you determine that there is an additional 1/4" of travel in the clutch fork and that you're not getting full engagement? For some reason, they installed the same type of slave on my car (I've also got a Roush, TKO600, and a Quicktime), but it has worked fine so far.

__________________

Doug

No stop signs, speed limit - Nobody's gonna slow me down - Like a wheel, gonna spin it

|

02-01-2010, 10:30 AM

|

|

CC Member

|

|

|

Join Date: Aug 2007

Location: Carlsbad,

Ca

Cobra Make, Engine: SPF 2932 with 438 Lykins Motorsports engine. Previous owner of FFR 5452.

Posts: 2,616

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Got the Bug

Jim,

How did you determine that there is an additional 1/4" of travel in the clutch fork and that you're not getting full engagement? For some reason, they installed the same type of slave on my car (I've also got a Roush, TKO600, and a Quicktime), but it has worked fine so far.

|

When I adjusted the M/C rod in the footwell as tight as I could (no freeplay whatsoever), then the grinding stopped, but just barely!

I'm going to try putting a thick washer between the fork and the end of the rod to get some additional length and see if that cures it. If so, then I will fabricate a longer rod and use lock nuts to adjust and secure it to the fork.

__________________

Jim

Last edited by jhv48; 02-01-2010 at 11:53 AM..

|

02-01-2010, 08:35 PM

|

|

CC Member

|

|

|

Join Date: May 2008

Location: San Jose CA,

CA

Cobra Make, Engine: SPF_R_/BRG/FRBoss302/327CI/FordEFI/Under_Car_Exh/

Posts: 2,523

|

|

Not Ranked

Not Ranked

I am not a big fan of these cylinders.

-- but I have had great luck with the wilwood pull type.

They are just about perfectly sized for most ford applications. -- working on a FE version now.

look at my t56 thread for pics. --

I would measure the distance traveled for full compression or expansion, and see if you are getting FULL travel of the cylinder.

Steve

__________________

Steve SPF 2734 MK3 / Brock Coupe #54- panavia.com

Last edited by PANAVIA; 03-04-2010 at 02:10 AM..

|

02-03-2010, 10:02 AM

|

|

CC Member

|

|

|

Join Date: Aug 2007

Location: Carlsbad,

Ca

Cobra Make, Engine: SPF 2932 with 438 Lykins Motorsports engine. Previous owner of FFR 5452.

Posts: 2,616

|

|

Not Ranked

Not Ranked

So,

I replaced the slave and bled the system. Trans still grinds in reverse no matter what gear you put it in first.

So now I got a 3/8 inch threaded rod and some washers and nuts. Going to make an adjustable push rod for the slave cylinder.

If this doesn't work, it's back to the installer.

__________________

Jim

|

02-03-2010, 10:33 AM

|

|

CC Member

|

|

|

Join Date: Oct 2007

Location: Livermore,

CA

Cobra Make, Engine: SPF 2168, 418, TKO 600

Posts: 203

|

|

Not Ranked

Not Ranked

Jim,

My car has a similar issue except it goes into reverse fine when it's cold, but not when it warms up.

Keep us posted if your fix works.

Dan

|

02-03-2010, 10:58 AM

|

|

CC Member / Sponsor

|

|

|

Join Date: Oct 2003

Cobra Make, Engine:

Posts: 808

|

|

Not Ranked

Not Ranked

many of the wilwoods pull types on Both SPF and BDR's were leaking after short miles due to improper alignment. Not just the pull types but the push as well. With a proper bracket design seems to help alot of the fixes for the push.

__________________

Squeaky wheel always gets the grease!!

www.gcperf.com

|

02-03-2010, 11:28 AM

|

|

CC Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine:

Posts: 3,077

|

|

Not Ranked

Not Ranked

Exactly mine would weep and once i modified the bracket to get it perpindicular no leakage in over a year, not a drop.

Quote:

Originally Posted by Blittleton

many of the wilwoods pull types on Both SPF and BDR's were leaking after short miles due to improper alignment. Not just the pull types but the push as well. With a proper bracket design seems to help alot of the fixes for the push.

|

|

02-03-2010, 12:19 PM

|

|

CC Member

|

|

|

Join Date: Aug 2007

Location: Carlsbad,

Ca

Cobra Make, Engine: SPF 2932 with 438 Lykins Motorsports engine. Previous owner of FFR 5452.

Posts: 2,616

|

|

Not Ranked

Not Ranked

I'm the one doing the weeping!

I'm going to install the rod tonight and will let you know tomorrow if it helped. Should be able to adjust all freeplay out of the system.

If that doesn't do it, I'm stumped!

__________________

Jim

Last edited by jhv48; 02-03-2010 at 12:21 PM..

|

02-03-2010, 02:50 PM

|

|

CC Member

|

|

|

Join Date: May 2001

Location: California,

Ca

Cobra Make, Engine: NAF 289 Slabside Early Comp Car with 289 Webers and all the goodies. Cancelling the efforts of several Priuses

Posts: 6,592

|

|

Not Ranked

Not Ranked

Blittleton has given you some good advice. If it was working OK before, that would indicate the sizing ratios are acceptable. When the rod is adjusted you must have a very small amount of freeplay to prevent the T/O Bearing from contacting the release levers on the clutch pressure plate. You may find you have some bad cup seals inside the master or slave cylinders.

__________________

Rick

As you slide down the Banister of Life, may the splinters never be pointing the wrong way

Last edited by Rick Parker; 02-03-2010 at 02:57 PM..

|

02-04-2010, 02:15 PM

|

|

CC Member

|

|

|

Join Date: Aug 2007

Location: Carlsbad,

Ca

Cobra Make, Engine: SPF 2932 with 438 Lykins Motorsports engine. Previous owner of FFR 5452.

Posts: 2,616

|

|

Not Ranked

Not Ranked

Update.

I fabricated a 3/8 inch threaded rod so that I could adjust the clutch play at the fork.

Adjusted all of the play out and then added about 1/4 inch of additional tension so that the fork was starting to compress a little bit.

Fired up the car, still grinds like hell in reverse. All other gears are smooth as silk. Clutch engages a little more than halfway out from the floor.

NOW WHAT? I'm out of ideas!

__________________

Jim

|

02-04-2010, 02:47 PM

|

|

CC Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine:

Posts: 3,077

|

|

Not Ranked

Not Ranked

always go to a foward gear just before reverse. for example, push clutch in, shift to third then shift to reverse holding clutch in all the time.

|

02-04-2010, 04:03 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jan 2007

Location: Sacramento,

CA

Cobra Make, Engine: Superformance 460 SVO

Posts: 305

|

|

Not Ranked

Not Ranked

x2 on the shifting into a forward gear first. also don't put too much preload on the t/o bearing, if it always on load, it will wear out quicker.

|

02-04-2010, 07:03 PM

|

|

CC Member

|

|

|

Join Date: Aug 2007

Location: Carlsbad,

Ca

Cobra Make, Engine: SPF 2932 with 438 Lykins Motorsports engine. Previous owner of FFR 5452.

Posts: 2,616

|

|

Not Ranked

Not Ranked

I have shifted into every gear prior to trying reverse. Still grinds.

__________________

Jim

|

02-04-2010, 07:56 PM

|

|

CC Member

|

|

|

Join Date: Sep 2003

Location: San Jose,

Ca

Cobra Make, Engine: SPF #1436 514

Posts: 1,489

|

|

Not Ranked

Not Ranked

Sound's familiar.

I seem to always have problems shifting into first and down shifting to third on the track. Made a heat shield for the clutch lines, changed the slave since it was leaking, had to make a new push rod since mine broke?????? Took my car for a ride the other day, and was getting flustered with the way it shifts. Haven't put it up on the stands yet to recheck the adjustment. I did have mine loosen up a while back even though I have a crushed lock nut on mine.

I have also changed the shift tower, shift lever and changed the pin position to the upper hole on the pedal since mine is a bear to push in. Since I did that, I get less travel so I had to raise the pedal a bit to get more travel.

Scott |

02-04-2010, 09:33 PM

|

|

CC Member

|

|

|

Join Date: Aug 2007

Location: Carlsbad,

Ca

Cobra Make, Engine: SPF 2932 with 438 Lykins Motorsports engine. Previous owner of FFR 5452.

Posts: 2,616

|

|

Not Ranked

Not Ranked

I'm beginning to understand why some of these cars have automatics!

__________________

Jim

|

02-05-2010, 08:54 AM

|

|

CC Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine:

Posts: 3,077

|

|

Not Ranked

Not Ranked

Something is being missed. I have a TKO 600 with standard slave and bracket and it works perfect. The only issue I had was weaping because the bracket was not alinged with fork.

what transmission do you have? where did you get your bracket? Are you using the Isuzu slave cylinder which comes with SPF's. If you push in on the clutch can someone push you down the street? If so it is not your clutch.

|

02-05-2010, 12:34 PM

|

|

CC Member

|

|

|

Join Date: Aug 2007

Location: Carlsbad,

Ca

Cobra Make, Engine: SPF 2932 with 438 Lykins Motorsports engine. Previous owner of FFR 5452.

Posts: 2,616

|

|

Not Ranked

Not Ranked

I took it to a local mechanic that does most of my normal engine work and showed him what I had done. He kept it the whole day and whenI picked it up said he couldn't get reverse to grind once and that the clutch was not dragging at all.

I got in it to drive home and started the engine with the clutch pedal to the floor, shifted into 4th and then slowly tried reverse..........GRIND.

What am I doing wrong?

__________________

Jim

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 06:10 PM.

Links monetized by VigLink

|