Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

|

1 |

| 2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 9 |

10 |

11 |

12 |

13 |

14 |

15 |

| 16 |

17 |

18 |

19 |

20 |

21 |

22 |

| 23 |

24 |

25 |

26 |

27 |

28 |

29 |

| 30 |

31 |

|

|

|

|

|

|

CC Advertisers

CC Advertisers

|

|

2Likes 2Likes

03-22-2011, 09:24 AM

|

|

CC Member

|

|

|

Join Date: Mar 2003

Location: McConnellsburg,

PA

Cobra Make, Engine: ERA FIA #2124

Posts: 687

|

|

Not Ranked

Not Ranked

Home-made Side Curtains for Lemans Top – “How To”.

Home-made Side Curtains for Lemans Top – “How To”.

I like to drive my Cobra, and I also like to be able to take my car out of the garage in the morning and not worry if it’s going to rain. So to get to this happy place, I decided to take on the task of fabricating side curtains or “screens” as you’ll find me calling them that fit the side window opening profile of the LeMans Hard Top that’s fitted to my car. In this little “how – to”, I’ll explain what inspired me to go the design direction I chose and provide a little step-by-step of the construction process

|

03-22-2011, 09:26 AM

|

|

CC Member

|

|

|

Join Date: Mar 2003

Location: McConnellsburg,

PA

Cobra Make, Engine: ERA FIA #2124

Posts: 687

|

|

Not Ranked

Not Ranked

Background:

Background:

The main criteria for these side screens was that they had to be made with the tools I either owned or had easy access to. It’s all pretty common stuff like saws, drills, propane torch, measuring tape, taps, riveters, and things of that nature. The second criteria was that when finished, they needed to represent a style that would not look out of place on a Cobra. Two pictures that inspired me to proceed with my intended design direction are shown here:

Notice that in the top photo there is a simple panel that slides in a track to allow access/ventilation, etc a la Daytona coupe. There’s no access panel in the screen shown in the second photo, but rather an Aircraft window “snap vent” for ventilation and some sort of extension on the interior door latch accessible through a small hole in the screen for opening the door. I chose to go the direction of the top photo. |

03-22-2011, 09:27 AM

|

|

CC Member

|

|

|

Join Date: Mar 2003

Location: McConnellsburg,

PA

Cobra Make, Engine: ERA FIA #2124

Posts: 687

|

|

Not Ranked

Not Ranked

Step 1 – Making the pattern.

Step 1 – Making the pattern.

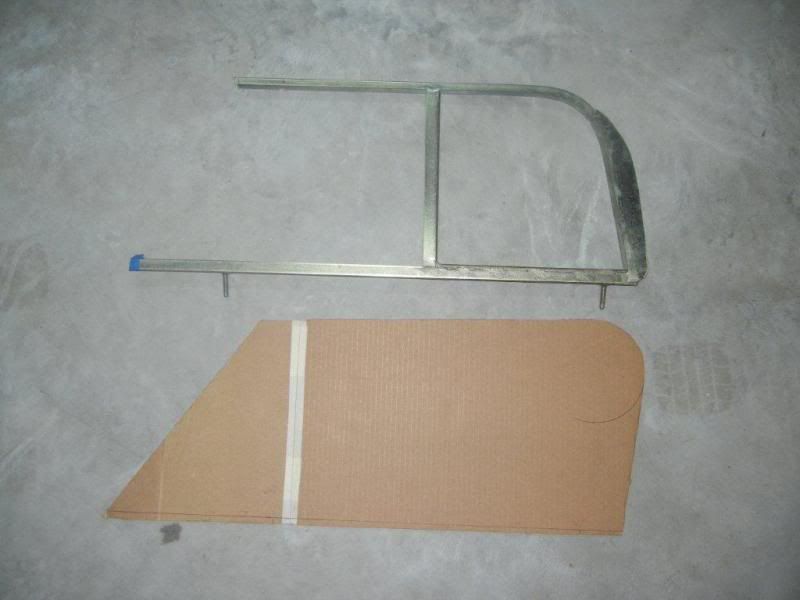

Now you might be asking yourself why I chose to go through all the trouble of making my own screens when there are folks with soft tops using them all day long. The reason for this is that the Lemans Hard Top has a different window opening profile than the standard Cobra Soft Top does. I realized this up front, but thought I could acquire a set of screen frames from Europa Spares and afford myself a jump-start on the fabrication process. Turned out, modifying the soft top frames was more trouble than it was worth and I aborted that option. Here’s a picture showing the cardboard pattern sitting in the side window opening followed by a picture of the soft top frame sitting next to it. The difference in the rear profile is pretty clear..

|

03-22-2011, 09:29 AM

|

|

CC Member

|

|

|

Join Date: Mar 2003

Location: McConnellsburg,

PA

Cobra Make, Engine: ERA FIA #2124

Posts: 687

|

|

Not Ranked

Not Ranked

Step 2 – Materials.

Step 2 – Materials.

The materials chosen for the construction included ¼” aluminum channel to make the boarder frame, 3/16” Polycarbonate sheet for the main window panel, thinner 0.080” sheet for the sliding window, 1/8”x ½” and 1/16”x ¾” stock for the sliding window tracks, some 1/16” sheet that would be bent to create the curtain base and provide a flange for the 5/16” aluminum rods to attach to which slot into the furrels located in the door. In addition to these items, I utilized some No8 and No10 machine screws, 1/8” rivets, and some assorted foam rubber seals. All this stuff can be acquired at McMaster Carr and Lowes.

|

03-22-2011, 09:31 AM

|

|

CC Member

|

|

|

Join Date: Mar 2003

Location: McConnellsburg,

PA

Cobra Make, Engine: ERA FIA #2124

Posts: 687

|

|

Not Ranked

Not Ranked

Step 3 – Construction.

Step 3 – Construction.

The thing that concerned me most about the screen design was the formed section of aluminum channel at the rear of the screens. I did a bit of google searching on this topic and found that the Locost guys have a cool way of doing it that utilizes a permanent marker (sharpie), a propane torch, and a piece of wood that slots in to the channel opening cut to the profile you wish to shape the channel to. Here’s the link to the Locost builder’s method that I borrowed:

http://www.locostusa.com/forums/view...t=6299&start=0

Basically, using the sharpie, you put some scribbly marks on the outside of the channel in the area you want to form and heat the channel from the inside. When the marks fade and disappear, the aluminum is annealed enough to form. I took it kind of slow and ended up annealing the channel a extra time or two to minimize the wrinkling. It takes a bit of trial and error. Here are my pics of the process:

You can see the marks starting to fade here:

After I was satisfied with the forming of the upper rear channel radius, I set off using my cardboard pattern to guide me in making the remainder of the frame. Here you can see some of that process. To make the angle bends, I just cut out “V” sections in the flange of the channel and bent to the desired angles:

After finishing both LH/RH frames, I used the frames to trace a cut-line on the piece of polycarbonate. I then used a fine-tooth blade on a jigsaw to cut out the main window panel. It cut like butter.

I then measured and cut the hole for my sliding window panel as well as the sliding panel itself. I drilled holes in the frames and the main window panel for attaching the two together with No8 machine screws.

This photo shows the 1/8”x ½” and 1/16”x ¾” stock for the sliding window tracks. The 1/8”x ½” piece gets sandwiched between the 1/16”x 3/4” piece and the main window panel to create a “track” for the sliding panel to slide in.

This next photo shows the two pieces of 1/16” sheet that was cut and bent to form the base of the screens. This piece also provides a flange for anchoring and attaching the screens to the top of the door.

|

03-22-2011, 09:35 AM

|

|

CC Member

|

|

|

Join Date: Mar 2003

Location: McConnellsburg,

PA

Cobra Make, Engine: ERA FIA #2124

Posts: 687

|

|

Not Ranked

Not Ranked

Step 4 – Assembly.

Step 4 – Assembly.

|

03-22-2011, 09:36 AM

|

|

CC Member

|

|

|

Join Date: Mar 2003

Location: McConnellsburg,

PA

Cobra Make, Engine: ERA FIA #2124

Posts: 687

|

|

Not Ranked

Not Ranked

Result.

Result.

And here’s what they look like fitted to the door:

They still require the rubber seal at the bottom flange of the screen as quite a bit of air comes in from under the screen while driving, I’ll update this thread with a photo once that is completed

I’m very pleased with the end result:

- Allen. |

03-22-2011, 10:27 AM

|

|

CC Member

|

|

|

Join Date: Mar 1999

Location: penn.,

Posts: 2,559

|

|

Not Ranked

Not Ranked

rocket science

|

03-22-2011, 10:58 AM

|

|

CC Member

|

|

|

Join Date: Dec 2010

Location: San Anselmo, Ca,

Ca

Cobra Make, Engine: Unique 289 FIA, 302

Posts: 80

|

|

Not Ranked

Not Ranked

Your car looks fantastic !!!!!

|

03-22-2011, 11:13 AM

|

|

CC Member

|

|

|

Join Date: Oct 2003

Posts: 4,078

|

|

Not Ranked

Not Ranked

Dude,

Seriously good concept, presentation and description-both text and photo. Have you done any technical writing professionally?

__________________

Chas.

|

03-22-2011, 01:08 PM

|

|

CC Member

|

|

|

Join Date: Mar 2003

Location: McConnellsburg,

PA

Cobra Make, Engine: ERA FIA #2124

Posts: 687

|

|

Not Ranked

Not Ranked

Technical writing....

Technical writing....

Quote:

Originally Posted by ERA Chas

Dude,

Seriously good concept, presentation and description-both text and photo. Have you done any technical writing professionally?

|

Thanks, Chas. Never been a technical writer, but I enjoy build threads, and as I remember, PSU required me to take a Technical Writing class as part of my BSME course work. BTW, I enjoyed the help you gave me in taking photos of your side curtains. I referred to them several times as I tried to wrap my head around which way I wanted to go.

I would like to see more technical stuff on this forum and thought I would make a contribution parallel to my ownership log for #2124. I also like to make things with my hands and this was a cool project that turned out really well. I'm glad I could make the contribution and maybe it will inspire someone else to do it too and maybe make some improvements!

- Allen. |

03-22-2011, 02:17 PM

|

|

CC Member

|

|

|

Join Date: Oct 2003

Posts: 4,078

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Fullchat289

Thanks, Chas. Never been a technical writer, but I enjoy build threads, and as I remember, PSU required me to take a Technical Writing class as part of my BSME course work. BTW, I enjoyed the help you gave me in taking photos of your side curtains. I referred to them several times as I tried to wrap my head around which way I wanted to go. Can't take credit for that Allen-you're thinking of someone else. I killed you about the ride-height. I don't have Mary stuff like top or curtains...:

I would like to see more technical stuff on this forum and thought I would make a contribution parallel to my ownership log for #2124. Me too X 1000. I also like to make things with my hands and this was a cool project that turned out really well. I'm glad I could make the contribution and maybe it will inspire someone else to do it too and maybe make some improvements!

- Allen. |

Hands-on guys appreciate you efforts-keep 'em coming.

__________________

Chas.

|

03-22-2011, 03:01 PM

|

|

CC Member

|

|

|

Join Date: Oct 2007

Location: Near Emerald,

Qld

Cobra Make, Engine: Evans kit, 6 litre, 6 speed, Jag F/R,

Posts: 366

|

|

Not Ranked

Not Ranked

Very clever and very informative.

Puts some ideas in my head now.

Great stuff, Thankyou.

__________________

Missed my Cobra budget by thaaaat much.

Ya get that on big jobs.

|

03-22-2011, 03:46 PM

|

|

CC Member

|

|

|

Join Date: Nov 2003

Location: New Britain,

CT

Cobra Make, Engine: Size 10 Feet

Posts: 3,024

|

|

Not Ranked

Not Ranked

Very nice. The main thing that I would have done differently is to substitute clear plexi for the aluminum channels for the sliding window. The channels could be made by machining a thicker piece into an "L" shape (with a very deep lower part) or gluing two pieces of plexi together. You just have to be very careful masking when you glue the channel onto the main window.

|

03-22-2011, 04:04 PM

|

|

Stolen Avitar

|

|

|

Join Date: Oct 2004

Location: Brunswick,

GA

Cobra Make, Engine: BDR 1311 428PI

Posts: 3,044

|

|

Not Ranked

Not Ranked

Great post and result man!

Steve

|

03-22-2011, 07:18 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Dec 2007

Cobra Make, Engine: ERA FIA 'Street' Build

Posts: 2,128

|

|

Not Ranked

Not Ranked

Allen,

Like the guys said, very well presented.

The step by step detail, photos and reasoning behind the fabrication is first rate. Something that a lot of folks could attempt with a very good likely hood of success, especially for those with more hands on experience.

It's easy to see that you have an engineering background and very cool to be able to fabricate some neat parts for your car.

What's next ?

- Tim |

03-23-2011, 07:21 AM

|

|

CC Member

|

|

|

Join Date: Mar 2003

Location: McConnellsburg,

PA

Cobra Make, Engine: ERA FIA #2124

Posts: 687

|

|

Not Ranked

Not Ranked

Chas:

You are right. It hit me on the ride home last night that you weren't the one who took pictures of the sidescreens for me. It was Patrick!!! 5 x 10^23 appologies for the mix-up. (Thanks again, Patrick!!)

Quote:

Originally Posted by strictlypersonl

Very nice. The main thing that I would have done differently is to substitute clear plexi for the aluminum channels for the sliding window. The channels could be made by machining a thicker piece into an "L" shape (with a very deep lower part) or gluing two pieces of plexi together. You just have to be very careful masking when you glue the channel onto the main window.

|

Bob: excellent suggestion. I'm pretty sure I could get the pieces from TAP Plastics and give it a shot. I like to be able to take stuff apart, so I would likely just get stock in the same sizes I did in aluminum and glue the two pieces together to create the "track" and still use the No8 hdwr to bolt them to the main window panel. I just may do that in my efforts to refine the screens..

Tim: What's next? Keep your eyes on my Ownership Log..... I know you are!

Everyone else: Thanks so much for the positive comments!

- Allen.

|

03-23-2011, 07:40 AM

|

|

CC Member

|

|

|

Join Date: Oct 2003

Posts: 4,078

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Fullchat289

Chas:

You are right. It hit me on the ride home last night that you weren't the one who took pictures of the sidescreens for me. It was Patrick!!! 5 x 10^23 appologies for the mix-up. (Thanks again, Patrick!!)

|

Oh great-now I've been confused with the Village Idiot...

__________________

Chas.

|

03-28-2011, 05:36 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Mar 2005

Location: Manchester,

NH

Cobra Make, Engine: AK1085 (302 Street), HTM111 (427 Comp), CSX2375R (289 Comp) and COB5999 (427 S/C)

Posts: 19,081

|

|

Not Ranked

Not Ranked

Great stuff, very informative and perfect for this forum. If I ever add a top to mine this will be usefull. Thanks for the post!

|

04-25-2011, 06:45 AM

|

|

CC Member

|

|

|

Join Date: Jan 2002

Location: Melbourne, Australia,

VIC

Cobra Make, Engine: AP Pace427 (AP4033) GM L77 6.0L TR6060

Posts: 838

|

|

Not Ranked

Not Ranked

Great work Allen! Like the others said, this will be a definite reference point when I get to that stage of my build!

Have you taken her out with these windows yet? How is the wind noise? Do you get any/much whistle?

And have you tried them in the wet? I am interested to know how much water gets through behind the sliding panel? (In any case, less than having NO windows - I imagine!).

__________________

Guy

Cobra Progress guye-cobra.blogspot.com

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -7. The time now is 12:43 AM.

Links monetized by VigLink

|