Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

December 2024

December 2024

|

| S |

M |

T |

W |

T |

F |

S |

| 1 |

2 |

3 |

4 |

5 |

6 |

7 |

| 8 |

9 |

10 |

11 |

12 |

13 |

14 |

| 15 |

16 |

17 |

18 |

19 |

20 |

21 |

| 22 |

23 |

24 |

25 |

26 |

27 |

28 |

| 29 |

30 |

31 |

|

|

|

|

|

CC Advertisers

CC Advertisers

|

|

04-12-2010, 03:33 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,005

|

|

Not Ranked

Not Ranked

And Brent, you would agree that there is no good reason not to use a spring on the fork, right?

|

-

Advertising

04-12-2010, 03:35 PM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

If your combo needs one, sure.

|

04-12-2010, 03:51 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2002

Cobra Make, Engine:

Posts: 15,712

|

|

Not Ranked

Not Ranked

Excellent answer Brent, can't go wrong with that.  Not all systems CAN use a return spring. Internal throw out bearing comes to mind, some cable systems could be problematic as well.

Personally I can't think of a single "fork" system with an external slave that couldn't benefit from a return spring. The slave cylinder piston MUST be totally bottomed out to get the proper adjustment. Some systems kind of sort of "self adjust" more than likely you got "lucky". There is only way to be sure, gotta spring it. |

04-12-2010, 03:54 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,005

|

|

Not Ranked

Not Ranked

I was only thinking of the old, traditional, external hydraulic fork. It's such a simple little component that I don't know why you wouldn't use one to extend the life of the TOB. And even if you don't believe it will, a return spring is so cheap that you ought to use one just in case you're wrong.  |

04-12-2010, 05:06 PM

|

|

CC Member

|

|

|

Join Date: Apr 2006

Location: Oakville,

Ont

Cobra Make, Engine:

Posts: 322

|

|

Not Ranked

Not Ranked

ok i tried the spring to return the fork, spring is not strong enough to pull it back, tried many springs , i just cant see why it needs so much pressure to pull the fork back, my bearing is always running on the pp. my only other option is to remove the internal spring.

now 1 more question, i have bled the dammm thing at least 50 times, ill even pull the fork all the way back and then tighten up the bleed screw, and all is fine, slave does not push out at all, ( it stays bottomed out) press the clutch and it goes right back to where it was before, WHAT GIVES???

|

04-12-2010, 05:11 PM

|

|

CC Member

|

|

|

Join Date: Sep 2009

Location: Hideaway, Texas,

TX

Cobra Make, Engine: Backdraft #318, 418 CI, 532 RWHP, Mass Flow Injected, TKO600-Road Race, BMW M3 Suspension, Race Springs (Wouldn't do it again, rough on the street).

Posts: 240

|

|

Not Ranked

Not Ranked

I just installed one of Bill Littleton's external push slave setups that has an internal return spring actually pushing the plunger back into the cylinder and pulling the bearing away from the pressure place fingers, just like an external return spring would. Works great and the slave is always bottomed and ready for full throw (1 3/8), so adjustment is super easy with the threaded body on the slave. It's not rocket science, but is sure works well. Looks cool too. Pictures available if anyone is interested.

__________________

Wayne Rogers in Hideaway, Texas

|

04-12-2010, 05:51 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,005

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by maxum_101

ok i tried the spring to return the fork, spring is not strong enough to pull it back, tried many springs , i just cant see why it needs so much pressure to pull the fork back, my bearing is always running on the pp. my only other option is to remove the internal spring.

WHAT GIVES???

|

There must be something binding. When I adjust my clutch (pic below), both the plunger coming out of the slave, and the fork itself, will easily push back towards the slave with nothing but light finger pressure. However, I do remember changing out clutch fork return springs decades ago that were very, very strong. So strong in fact that you were afraid of trying to pull them with vise grips because, if they slipped, they could do some damage to you. Instead, we would bend the springs open and put coins between each round of the spring, maybe a dozen or so, and that would spread the spring out so you could easily put it on. Then you would just pull the coins out one by one. I haven't thought of that in a good 30+ years.

|

04-12-2010, 07:52 PM

|

|

CC Member

|

|

|

Join Date: Aug 2007

Location: Carlsbad,

Ca

Cobra Make, Engine: SPF 2932 with 438 Lykins Motorsports engine. Previous owner of FFR 5452.

Posts: 2,616

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by maxum_101

ok i tried the spring to return the fork, spring is not strong enough to pull it back, tried many springs , i just cant see why it needs so much pressure to pull the fork back, my bearing is always running on the pp. my only other option is to remove the internal spring.

now 1 more question, i have bled the dammm thing at least 50 times, ill even pull the fork all the way back and then tighten up the bleed screw, and all is fine, slave does not push out at all, ( it stays bottomed out) press the clutch and it goes right back to where it was before, WHAT GIVES???

|

When you bleed it, you must force the plunger BACK INTO the sleeve before you attempt the next bleed. Connect it to the shift fork so the pressure of the fork pushes it back into bottom of the sleeve.

__________________

Jim

|

04-12-2010, 08:08 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2002

Cobra Make, Engine:

Posts: 15,712

|

|

Not Ranked

Not Ranked

Thats a good point jhv48, the return spring, even a strong one, can be some what slow to react. Some slaves bleed off the hydraulic fluid through the line back to the master faster than others. The spring needs to be strong enough to:

1. Eventually bottom out the slave plunger.

2. Overcome the slave internal spring pressure.

You WILL likely have to push/pull whatever with your hand to get the slave piston bottomed out for the initial adjustment. Or, just keep cranking on the adjustment rod until you KNOW you have bottomed that plunger out. It may well surprise you how far out of adjustment your rod is, you may have to turn the adjustment nut/bolt a LOT to catch up.

|

04-13-2010, 08:00 AM

|

|

CC Member

|

|

|

Join Date: Apr 2006

Location: Oakville,

Ont

Cobra Make, Engine:

Posts: 322

|

|

Not Ranked

Not Ranked

ok so i should bottom out the slave hold it then have someone push clutch peddle in and then bleed it? i have an adjustable rod but it is useless cause the slave just keeps pushing out, and pushes the bearing against the PP.

that why i ask about the internal slave spring,

|

04-13-2010, 08:25 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2002

Cobra Make, Engine:

Posts: 15,712

|

|

Not Ranked

Not Ranked

I don't think bleeding the slave is the answer here, my guess is you have already done that enough. It's very easy to get the air out of this type of system. The slave piston is moving out because of it's internal spring, that's OK. You need an external spring to overcome the natural and expected movement of the slave piston.

If your existing return spring is not able to seat the slave piston and provide some clearance on the pressure plate fingers the spring is not strong enough, or is not mounted correctly. There is no reason other than the internal spring for your slave piston to move toward the end of it's stroke. More bleeding likely won't have anything to do with this issue, I think it's a red herring.

|

04-13-2010, 08:36 AM

|

|

CC Member

|

|

|

Join Date: Aug 2007

Location: Carlsbad,

Ca

Cobra Make, Engine: SPF 2932 with 438 Lykins Motorsports engine. Previous owner of FFR 5452.

Posts: 2,616

|

|

Not Ranked

Not Ranked

Maxum 101

I just went through this whole process with the constant pressure on the fork. I went through the whole replacement, bleeding, replacing the rod with a threaded rod, etc. I even considered converting to a pull type slave or getting one of the forum members custom bracket and slave that has no internal spring.

After discussing it with the installer, who does SPF's all day long for Hillbank in Irvine, they assured me that the push type with the internal spring intact will be fine and that the constant pressure on the throwout bearing will not cause it to fail, They have never seen one fail yet.

So, install the pusher and don't worry about it. Or get the bracket and slave from one of our members (do a search for BDR slave cylinders and you should find pics and prices). I think Vintage sells them.

Good luck. Either will work just fine.

__________________

Jim

|

04-13-2010, 09:22 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2002

Cobra Make, Engine:

Posts: 15,712

|

|

Not Ranked

Not Ranked

jhv, instead of going through "all that" why didn't you simply put a return spring on it and solved the problem in the first place? I'd rather follow a clutch manufacturers specifications than an SPF builder. If those guys have never seen a throw out bearing fail, there are not doing any serious mechanic work. It is likely their customers drive less than 500 miles a YEAR.

I'm I the only guy here that actually DRIVES his car? If your only going to put 500 to 1500 miles on it, yeah, DUH, the throw out bearing isn't an issue. I've got 20,000 on mine...

|

04-13-2010, 10:07 AM

|

|

CC Member

|

|

|

Join Date: Apr 2006

Location: Oakville,

Ont

Cobra Make, Engine:

Posts: 322

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Excaliber

jhv, instead of going through "all that" why didn't you simply put a return spring on it and solved the problem in the first place? I'd rather follow a clutch manufacturers specifications than an SPF builder. If those guys have never seen a throw out bearing fail, there are not doing any serious mechanic work. It is likely their customers drive less than 500 miles a YEAR.

I'm I the only guy here that actually DRIVES his car? If your only going to put 500 to 1500 miles on it, yeah, DUH, the throw out bearing isn't an issue. I've got 20,000 on mine...

|

ok i do agree with you, but i have put a spring on mine and it did not do a thing, and i tried all diffrent rates of springs, some that were so strong that i had a hard time stretching it to put it on,, and it still did not work. do i have a slave from hell or what??? mind you if i push the fork back (bottom out) there is more then enough clearance for the bearing not to be riding on the PP.

what is it that some spf owners have no problems and some do... is it a diffrent slave they have or is it the set they have. we have to got to get to the end of this for it seems to be a bull Sh*t problem

like a engine is an engine be it a 351 w or a 427 big block the tranny is the same , bell housing is the same blow proof or factory bell housing,... meaning there are no diffrences but yet some have the problem and some dont, there has to be an issue with the type or brand of slave being used.

i think the only way to figure this out is to have a poll.....members post up what slave they have and if they have that issue of the slave pushing the bearing against the PP all the time or not.

Last edited by maxum_101; 04-13-2010 at 10:17 AM..

|

04-13-2010, 10:21 AM

|

|

CC Member

|

|

|

Join Date: Aug 2007

Location: Carlsbad,

Ca

Cobra Make, Engine: SPF 2932 with 438 Lykins Motorsports engine. Previous owner of FFR 5452.

Posts: 2,616

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Excaliber

jhv, instead of going through "all that" why didn't you simply put a return spring on it and solved the problem in the first place? I'd rather follow a clutch manufacturers specifications than an SPF builder. If those guys have never seen a throw out bearing fail, there are not doing any serious mechanic work. It is likely their customers drive less than 500 miles a YEAR.

I'm I the only guy here that actually DRIVES his car? If your only going to put 500 to 1500 miles on it, yeah, DUH, the throw out bearing isn't an issue. I've got 20,000 on mine...

|

First of all, if I put a return spring on the fork to counteract the slave's internal spring, I would have to use a spring the size of a garage door spring.

Second, if this setup is approved by SPF, it's good enough for me.

Third, I drive my car about 6000 miles a year, this is my second Cobra and I haven't seen, or heard in any of the forums, about anyone that had a throwout bearing fail yet that had a continuous pressure slave cylinder.

Now, just you watch, mine will be the first!

__________________

Jim

|

04-13-2010, 10:22 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2002

Cobra Make, Engine:

Posts: 15,712

|

|

Not Ranked

Not Ranked

This is indeed a BS problem, I'm amazed this whole issue is still up for debate. It really is a no brainer. ALL the major clutch manufacturers recommend clearance, Ford (they choose NOT to change the design in spite of problems with it) and ONE SPF dealer with obviously limited experience dont'. Go figure this is even a debate...

Now where were we...

If you can push the fork back, with your hand on the end of the fork, and bottom the slave piston that's how much "force" it takes. Not "that much" in other words. So if the return spring is unable to pull the fork back far enough the angle of the pull may be binding the rod preventing free movement or the spring is not connected with enough "leverage" to do the job. It does require a fairly healthy spring, but not a killer spring!

So, assuming the spring is correct tension and mounted properly then some other force is pushing the slave piston out of it's bore. I could hazard some far out guess' none of them reasonable or logical though. The master is somehow maintaing pressure pushing fluid into the slave at rest. The slave hydraulic line to the master is blocked or restricted in some way. Once the slave gets some pressure it does not properly release the pressure (piece of debris in the line, blockage of some kind). The internal spring in the slave is "bad to the bone".

|

04-13-2010, 10:26 AM

|

|

CC Member

|

|

|

Join Date: Apr 2006

Location: Oakville,

Ont

Cobra Make, Engine:

Posts: 322

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by wrogers55

I just installed one of Bill Littleton's external push slave setups that has an internal return spring actually pushing the plunger back into the cylinder and pulling the bearing away from the pressure place fingers, just like an external return spring would. Works great and the slave is always bottomed and ready for full throw (1 3/8), so adjustment is super easy with the threaded body on the slave. It's not rocket science, but is sure works well. Looks cool too. Pictures available if anyone is interested.

|

yes please could you send me those pictures you have, it would be a great help.

just to make sure... you say it has an internal spring pushing the cyl back into itself (bottom out). ? |

04-13-2010, 10:33 AM

|

|

CC Member

|

|

|

Join Date: Aug 2007

Location: Carlsbad,

Ca

Cobra Make, Engine: SPF 2932 with 438 Lykins Motorsports engine. Previous owner of FFR 5452.

Posts: 2,616

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by maxum_101

yes please could you send me those pictures you have, it would be a great help.

just to make sure... you say it has an internal spring pushing the cyl back into itself (bottom out). ?

|

I would like to see a picture of that one too.

Not opposed to change.

__________________

Jim

|

04-13-2010, 11:35 AM

|

|

CC Member

|

|

|

Join Date: Sep 2009

Location: Hideaway, Texas,

TX

Cobra Make, Engine: Backdraft #318, 418 CI, 532 RWHP, Mass Flow Injected, TKO600-Road Race, BMW M3 Suspension, Race Springs (Wouldn't do it again, rough on the street).

Posts: 240

|

|

Not Ranked

Not Ranked

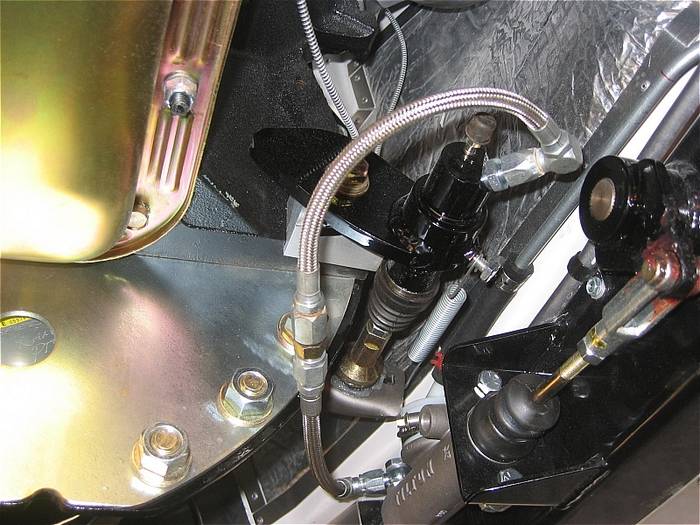

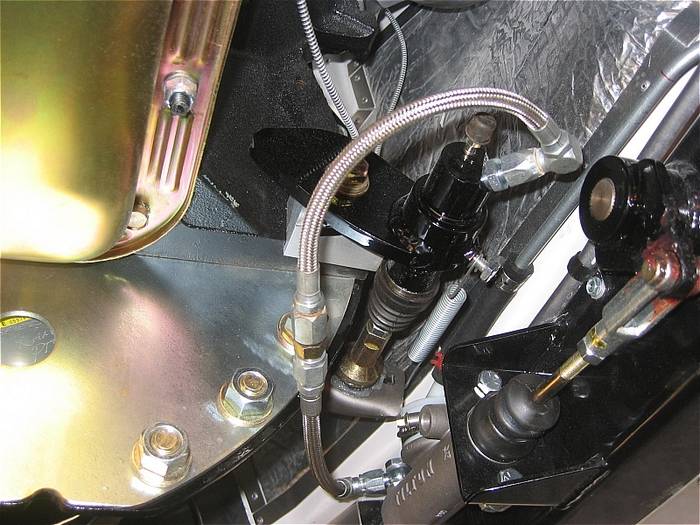

Here's the best picture I can get, as requested. The slave has a pretty strong spring that pushes the plunger "closed" or back toward the end where the bleeder is when there is no pressure. It is a pretty strong spring and pulls the fork arm back toward the back of the car as soon as the pressure is released.

I have a threaded rod adjuster...BUT, the best way to adjust this one is to loosen the body nut on the slave and just move it where you want it a few flats at a time, then tighten up the opposite lock nut on the slave body.

Also, just for the threaded rod guys. If you cut the spherical bearing end out of an old rod end that has the right diameter for your threaded rod and use that as the contact end of your threaded rod to the fork arm, it works great and will never wear out. Not a new idea, but really simple and works forever.

You can get the parts and fab it up, the slave is racing part from another world, or just call Bill Littleton at GCPC, he's already done all the work and it fits like a glove. Good guy to deal with.

Hope this helps.

__________________

Wayne Rogers in Hideaway, Texas

|

04-13-2010, 12:24 PM

|

|

CC Member

|

|

|

Join Date: Aug 2007

Location: Carlsbad,

Ca

Cobra Make, Engine: SPF 2932 with 438 Lykins Motorsports engine. Previous owner of FFR 5452.

Posts: 2,616

|

|

Not Ranked

Not Ranked

Here are some better pictures in another thread.

SPF Slave Cylinder Help.

__________________

Jim

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 08:17 AM.

|

Not all systems CAN use a return spring. Internal throw out bearing comes to mind, some cable systems could be problematic as well.

Not all systems CAN use a return spring. Internal throw out bearing comes to mind, some cable systems could be problematic as well.

Linear Mode

Linear Mode