Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

November 2024

November 2024

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

1 |

2 |

| 3 |

4 |

5 |

6 |

7 |

8 |

9 |

| 10 |

11 |

12 |

13 |

14 |

15 |

16 |

| 17 |

18 |

19 |

20 |

21 |

22 |

23 |

| 24 |

25 |

26 |

27 |

28 |

29 |

30 |

|

CC Advertisers

CC Advertisers

|

|

03-19-2011, 06:20 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: May 2001

Location: Florence,

AL

Cobra Make, Engine: RCR GT 40 & 1966 Fairlane 390 5 speed

Posts: 4,511

|

|

Not Ranked

Not Ranked

Electric clutch problem in a Cobra, help

Electric clutch problem in a Cobra, help

LT Jeff need some design help. This is his email to me. I know someone in the CC family can help redesign or find a new system that will work. LT lost a leg in Iran but build his FFR Cobra with a clutch set up for his wife. He installed a electric servo so he could activate the clutch by hand switch on the shifter. The company that made the system is out of business and he has talked to people in Italy and California about the system. This is where he is today.

Help?? Anyone?

Dwight

Dwight,

Last weekend Erik helped me install the duck clutch shifter system into my roadster. Since the duck system servo ONLY has 44mm ('bout 1 3/4") we had to attach it farther up the clutch pedal than we had previously. Erik welded in some bracing for the duck system and got it all looking nice. We turned on the system and it only pulled the clutch in half way!!....at best!! I have been told by a disability company in Arkansas that they have installed this system on a 2010 GT500. The servo which I was told is rated for 160 lbs is not strong enough to pull my clutch pedal. Basically as it stands now, I'm screwed.

I'm going to Home Depot tomorrow and picking up an outdoor hanging scale so that I can start doing some math. I need to figure out the work necessary to push the clutch by getting lbs needed to push the pedal and the travel. If I have some figures it will give me some stats to help me while looking at my options.

My current setup:

Ford Crate 392 (dyno w/ 438 engine hp, 374 rw hp, 391 rw tq)

Tremec TKO 600 w/ King Cobra pressure plate

Wilwood pedal assembly that came with the FFR complete kit

Current options:

1) Mount servo on 4" tube frame and attach it's cable directly to trans clutch fork to help eliminate frictional losses

- If it can't pull a clutch pedal with a mech advantage, being able to move the tab at the trans is very doubtful

- I don't see the frictional losses occurring from pedal setup and clutch cable/sleeve to be significant enough to matter (hence the calculations I'll be doing)

2) Look at hydraulic systems and see if I can gain anything from them

- Get as close to the GT500 setup as I can with the reservoirs since I know it works....... (but it has a 4.6 w/ a T56 trans and I do not)

- Adjust master and slave sizes to decrease effort needed (but increase throw = bad)

3) See if there is a 'easier' pressure plate than the King Cobra I have

- I've been told the King Cobra is on the easy end of the spectrum

- potentially move to a dual plate setup

4) After exhausting options 1, 2 and 3, look at replacing the TKO 600 with an automatic/paddle shifter setup

- take away the manual shift Katie and I were really hoping on

- option is either a paddle shift set up or a 'bump-shift' lever located on trans tunnel in place of manual shifter ( http://mastershift.com/new-street-auto.html)

--

Jeffrey S. Adams

1LT (ret), ENGR, US ARMY

Cell 225-803-1145

smada001@gmail.com

__________________

''Life's tough.....it's even tougher if you're stupid.'' ~ John Wayne

"Happiness Is A Belt-Fed Weapon"

life's goal should be; "to be smarter than inanimate objects"

Last edited by Dwight; 03-19-2011 at 06:22 AM..

Reason: add pic

|

-

Advertising

03-19-2011, 06:32 AM

|

|

CC Member

|

|

|

Join Date: Jun 2008

Location: Chester Springs,

PA

Cobra Make, Engine: Kirkham 289 FIA #690, FRPP 427 Boss engine

Posts: 764

|

|

Not Ranked

Not Ranked

I don't have a great answer, however, Mike Forte at Forte's Parts Connection can probably help. Here's Mike's website: http://www.fortesparts.com/

Also, please pass along my families heartfelt thanks for Jeff's service and huge sacrifice for our country.

__________________

RCR GT40 SOLD to Fast 5

Kirkham #690 289 FIA

|

03-19-2011, 06:56 AM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,415

|

|

Not Ranked

Not Ranked

I was able to speak to Jeff yesterday about this. It's a very interesting setup and since Jeff and I are both mechanical engineers, we got to get back to our roots while discussing designs...

We did come up with a few options that he could mull over...

The first one is a fork extension. He has already ordered one and that will be the first thing that he is to try.

The second idea is to swap to a hydraulic master/slave combination. Changing master cylinder size will allow him to "tune" the pedal pressure.

The third idea is to drop the King Cobra pressure plate (about 2600 lbs clamping force) in favor of a lighter pressure McLeod or RAM pressure plate.

Obviously it would be easier to try stuff that doesn't involve dropping the trans and bell, so we kinda arranged our options in terms of complexity.

|

03-19-2011, 07:04 AM

|

|

CC Member

|

|

|

Join Date: Jun 2008

Location: Chester Springs,

PA

Cobra Make, Engine: Kirkham 289 FIA #690, FRPP 427 Boss engine

Posts: 764

|

|

Not Ranked

Not Ranked

Obviously not a simple solution, but an AOD would also address the issue. Is an auto tranny out of the question?

__________________

RCR GT40 SOLD to Fast 5

Kirkham #690 289 FIA

|

03-19-2011, 07:24 AM

|

|

CC Member

|

|

|

Join Date: Feb 2009

Posts: 1,695

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by mreid

Obviously not a simple solution, but an AOD would also address the issue. Is an auto tranny out of the question?

|

I have to agree. Why not just put an AOD with a full manual valve body? The shifts would rip your face off if you wanted and save a lot of hassle. |

05-23-2011, 07:47 AM

|

|

CC Member

|

|

|

Join Date: Mar 2011

Location: Huntsville,

AL

Cobra Make, Engine: Factory Five Mk 3.1: 392 (438hp) Ford Racing Crate; 391rwtq, 374rwhp, TKO600

Posts: 5

|

|

Not Ranked

Not Ranked

All,

First off, thanks to all the replies and help on this issue. My name is Jeffrey and I was having the issue that Dwight mentioned in the first post. My original set up was a 392 (430hp) Ford crate engine w/ a TKO 600 and a King Cobra clutch. I have a 'Duck Clutch' system that allows me to operate my clutch pedal via a trigger on my shifter knob. The issue I ran into is that the servo that pulls the pedal for the system, which can pull 165lbs, was not able to pull my clutch pedal initially.

After much research and trying a few options (including Forte's fork extender....thanks Mike), I finally settled on getting a dual clutch with some custom pieces to make it as light as possible. Dwight and a few N. Alabama Cobra Club guys came over two weeks ago and got the two clutches swapped. That did the trick. Now the pedal moves as slick as owl crap on a tin roof.

I'm still curious as to what's making the original King Cobra as stiff as it is. The consensus from Dwight and a few others is that it was still much stiffer than it should have been. Regardless, I'm rocking and rolling now and have been go-carting my Factory Five around the neighborhood quite a bit. Thanks to the VERY DIFFICULT Alabama registration process (sarcasm), I'm registered and insured. In the next day or two another Cobra Club member here is going to help me get the chassis to the body shop w/ his trailer.

The body itself has been at the shop for a little over a month and they've sanded and done as much as they can w/o the chassis. Once the body work is complete, we'll do a full mock up before tearing it down for paint. While the body's off for paint, I'll insulate/carpet the interior, replace my temp dash w/ a carbon fiber one, and re-mount the seats so that they are a little more forward facing.

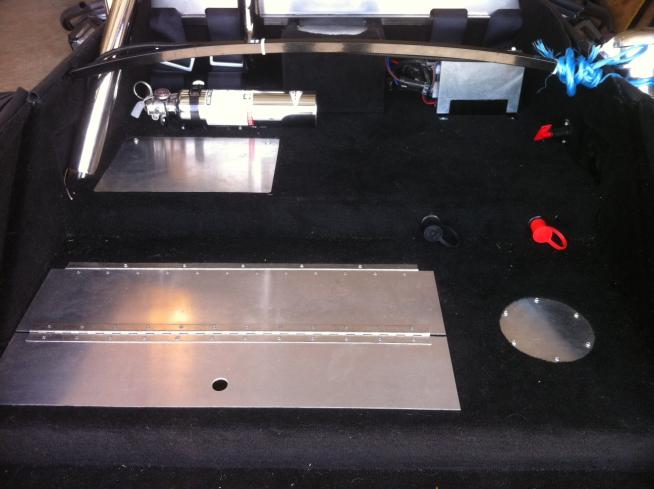

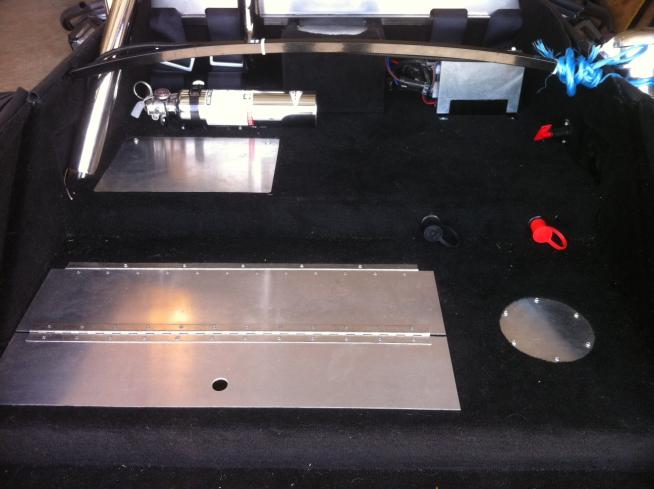

I've inclosed a few pictures of the build so far. Three of them are of the duck shifter handle (yes, set screws will replace the bolts), the black servo mounted on the front x-member, and how we mounted the servo cable to the pedal assembly (will clean up the bracing at the body shop). The others are just a few of the rest of the build. Almost there!!

______________________

Jeffrey - If the world didn't suck, we'd all fly off.

Last edited by smada001; 05-23-2011 at 08:05 AM..

|

05-23-2011, 07:49 AM

|

|

CC Member

|

|

|

Join Date: Mar 2011

Location: Huntsville,

AL

Cobra Make, Engine: Factory Five Mk 3.1: 392 (438hp) Ford Racing Crate; 391rwtq, 374rwhp, TKO600

Posts: 5

|

|

Not Ranked

Not Ranked

A few more pictures......

______________________

Jeffrey - If the world didn't suck, we'd all fly off.

Last edited by smada001; 05-23-2011 at 07:55 AM..

|

05-23-2011, 10:56 AM

|

|

CC Member

|

|

|

Join Date: Jun 2006

Location: Cape Coral,

FL

Cobra Make, Engine: Homebuilt, .060 over 428 FE Dual Quad

Posts: 101

|

|

Not Ranked

Not Ranked

Jeff,

Just curious, how does the clutch activate in first gear from a stop? How does it feather? And do you get instant engagement for the rest of the gears after you are moving? Cool setup. Thanks for your service.

Thanks,

Anthony

|

05-23-2011, 12:11 PM

|

|

CC Member

|

|

|

Join Date: Mar 2011

Location: Huntsville,

AL

Cobra Make, Engine: Factory Five Mk 3.1: 392 (438hp) Ford Racing Crate; 391rwtq, 374rwhp, TKO600

Posts: 5

|

|

Not Ranked

Not Ranked

Anthony,

The trigger allows for you to feather. For example, I move the trigger 1mm, the clutch moves 1cm. It's not an all or nothing. It's tricky to find the sweet spot however considering there is NO resistance feedback on the trigger. It's kind of a mix between using a hand clutch on a motorcycle and shifting a car on a video game with a controller.

The response from trigger pull to clutch pedal movement is instant with no lag. The Italian company I got the system from (Guidosimplex) mentioned that many rally drivers have installed this system because of the responsiveness and the speed at which it pulls/feathers the clutch pedal. It will just take time for me to build up the muscle memory (fingers in relation to palm) and engine sounds to know when I'm at the 'sweet spot' with the trigger while shifting. It reminds me of trying to find the sweet spot when I was first learning to shift a manual.

Too bad I don't have enough time to take it up to the London show this year. I'd love to show the system off as well as the rest of the car the Dwight and the crew have helped me put together.

__________________

LT - If the world didn't suck, we'd all fly off

|

05-31-2011, 09:47 PM

|

|

CC Member

|

|

|

Join Date: May 2008

Location: San Jose CA,

CA

Cobra Make, Engine: SPF_R_/BRG/FRBoss302/327CI/FordEFI/Under_Car_Exh/

Posts: 2,523

|

|

Not Ranked

Not Ranked

Agreed with the posting on the King Cobra PP ' that PP is way too hard to move, - try it with a stocker clutch and get the action working, then beef up.

__________________

Steve SPF 2734 MK3 / Brock Coupe #54- panavia.com

|

06-01-2011, 05:27 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Aug 1999

Location: Ellington,

CT

Cobra Make, Engine: Classic Roadster 351W, T5, Red & White

Posts: 3,478

|

|

Not Ranked

Not Ranked

Using " handicap clutch servo " as the search term, 2 examples of the search results, not knowing if the companies are still in business nor any personal experience with the application.

Drivematic

Adaptable And Transferable

The Drivematic system can be installed in any domestic or foreign vehicle and can be easily transferred from one vehicle to another, incurring only labor and minor hardware costs.

Persons who are unable to accomplish the clutching function, but need to drive a manual transmission for personal or professional reasons may now consider the Drivematic system as a practical option to an automobile or even a career change.

Many persons who are fully capable of using a standard clutch may also fund the Drivematic system attractive for its pure convenience, especially in stop and go traffic, and for tractor trailer and utility vehicles which are not available with automatic transmissions, Drivematic frees you from the task of clutching without a loss of "feel" or control.

Shift With Precision And Ease

Upon touch the gearshift lever knob, the Drivematic automatically depresses the clutch pedal. Once in gear, accelerate, and let Drivematic do the rest! Shifting gears is accomplished in a standard manner, in the style that you are accustomed to, only without the need to operate the clutch.

Hand Controls for Clutch

Does anyone know if there is such a beast as a hand control for a clutch? My left knee has cr*pped out on me and I have been thinking of ways to get around converting my beloved bus from a manual shift...

What is probably the slickest set of controls is the "Drive-Matic" automatic clutch system. This works very much like the bug's auto stick shift. It has a microswitch on the gearshift lever and engages the clutch when you touch it.

For more information contact:

ACCESS UNLIMITED

570 Hance Rd

Binghampton NY 13903

(607) 669 4822

The hand controls I have on my van, and the ones I like (so much so that I am now a distributor) are the Handicaps Inc. These controls will operate up to two functions gas/brake, gas/clutch, etc and work well on an automatic van.

For more info contact me or:

Handicaps Inc

4335 So Santa Fe Drive

Englewood CO 80110

800-782-4335

__________________

2014 Porsche Cayman S, 2014 M-B CLA 45 AMG,

Unkown:"Their sweet lines all but take my breath away, and I desire them as much for their beauty as for their use "

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 09:59 AM.

|

Linear Mode

Linear Mode