Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

December 2024

December 2024

|

| S |

M |

T |

W |

T |

F |

S |

| 1 |

2 |

3 |

4 |

5 |

6 |

7 |

| 8 |

9 |

10 |

11 |

12 |

13 |

14 |

| 15 |

16 |

17 |

18 |

19 |

20 |

21 |

| 22 |

23 |

24 |

25 |

26 |

27 |

28 |

| 29 |

30 |

31 |

|

|

|

|

|

CC Advertisers

CC Advertisers

|

|

07-03-2008, 03:22 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,005

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by tcrist

Norcal,

I think that maybe the slave mounts to a bracket that mounts to the engine. That way everything moves at the same time. You just need to have a flex line to your slave.

|

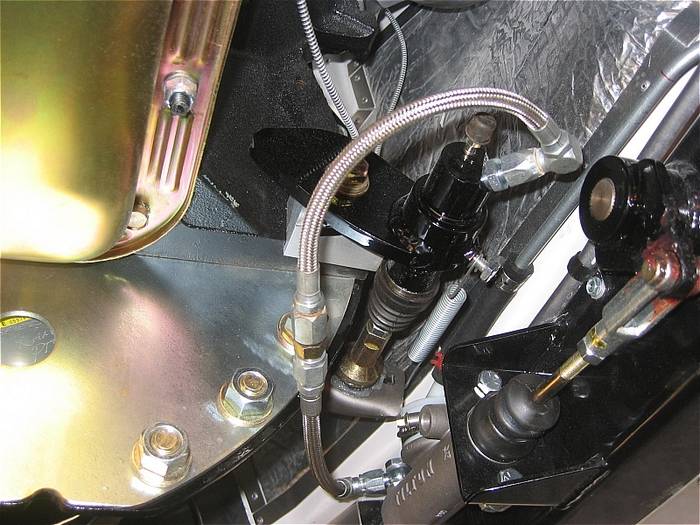

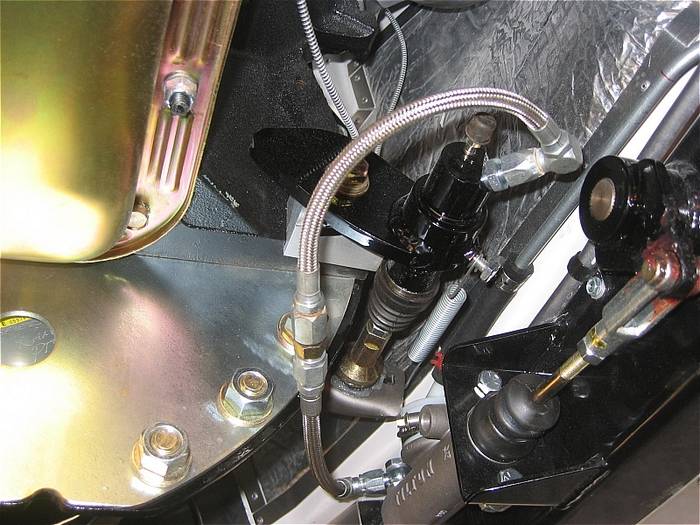

On an FE, the bracket can go right to the back of the block with the help of a spacer to align it properly, then all you need is the flex hose. Here's a pic of my setup:

|

-

Advertising

07-03-2008, 03:33 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Feb 2004

Cobra Make, Engine:

Posts: 1,226

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by NorCal Cobra

Why would it make a difference if the heim joint is attached to the frame vs. the engine mount? Both are fixed rigid points on the car that allow very slight movement, if any.

I'm just trying to understand the dynamics of the setup. Unfortunately I have a Lakewood Belhousing and the clutch fork extends much lower (further away from the engine) than with Quicktime and others out there.

Since the slave cylinder sits so much lower, it is very difficult to fabricate a bracket that would attach to the engine mount.

|

Mounting the slave cyl. to the frame is fine. I know many that have done it, including myself, and there has never been a problem. Yours was fine for the first 2000 miles. If it worked then, it works now. You just have to figure out what has changed recently that is causing the chatter. 90% of the time it is a contaminated disc from an oil leak. |

07-03-2008, 04:45 PM

|

|

CC Member

|

|

|

Join Date: Jul 2006

Location: Folsom,

CA

Cobra Make, Engine: Backdraft 427 Stroker, Sterling Gray/Silver

Posts: 68

|

|

Not Ranked

Not Ranked

I guess I should have mentioned that I completely changed my slave cylinder configuration two weeks ago.

That last slave cylinder (non -Willwood type) blew out was not secured to the frame. It was just butted up against a hole in the bellhousing with the clutchfork tension acting as the securing device. No wonder why it blew out!!

It was a very poor setup and the new Wilwood cylinder I received required modification to keep it secure and free from excessive play.

I have had clutch chatter before and after changing to the Wilwood, but now the chatter is much worse.

It could be a combination of slave setiup and disc contamination. Who knows????????

|

07-03-2008, 05:59 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Feb 2006

Location: Peachtree City,

GA

Cobra Make, Engine: BDR - 351 / 385 hp

Posts: 230

|

|

Not Ranked

Not Ranked

Multiple slave cylinders

Multiple slave cylinders

Al,

My first wilwood was mounted as yours was, it failed. The second came with instructions to mount it on the frame. It chattered & failed.  I made my own mount for the third one. It is holding up fine. Another issue with some Wilwoods is that the piston unscrews from the rod. This was a part of my problem with the second one. I really believe the vibration from the two mountings you have tried could be the cause or a part of the cause of the failure and the chattering. It won't cost much to try a solid mont to the engine before embarking on a transmission & clutch removal.

Good luck, Paul

__________________

Speedy

|

07-03-2008, 07:06 PM

|

|

CC Member

|

|

|

Join Date: Dec 2003

Location: Wilton,

CT

Cobra Make, Engine: Performance Cars Venom 427 Keith Craft 408 Stroker

Posts: 317

|

|

Not Ranked

Not Ranked

NorCal, it seems totally obvious to me what your problem is. Yes, just leaving the slave dangling in the bellhousing is really sloppy stuff, and yes, this setup will ultimately fail. However, note that you did not have clutch chatter. Now you mounted the slave to the frame, and guess what? Your slave isn't going to fall out of the car, but you have clutch chatter. Jay at Vintage Motorsport (A northeast Backdraft dealer) sold me a bracket that attached to the engine mounts. The engine mounts MOVE WITH THE MOTOR since they sit on a big rubber bushing*that absorbs the torque of the motor. When you start in 1st gear, it's all torque, and the motor moves a lot, changing the alignment of your frame mounted slave to the clutch fork, resulting in chatter.

I too was convinced that I had some kind of driveshaft alignment or clutch installation problem, and I would not believe the solution was this easy, but it was.

Call Jay or send him an email, and see if he will sell you one of his fabricated slave brackets. Maybe your local Backdraft dealer will do the same.

The installation is easy-breezy.

__________________

If I can see you, I'm too close

|

07-03-2008, 09:23 PM

|

|

CC Member

|

|

|

Join Date: Nov 2000

Location: Flower Mound, TX,

tx

Cobra Make, Engine: Lonestar LS 427, Keith Craft 501,Toploader

Posts: 883

|

|

Not Ranked

Not Ranked

If you have a clutch chatter problem, you will always only have it starting off in 1st gear. If you pull everything apart, more than likely, you'll find the problem is a semi-glazed flywheel. This is usually caused by a poor clutch releasing procedure. I don't know if you do this or not, but you should always start off with the engine RPM comming down and not rising.

__________________

" It ain't no big deal"

|

07-03-2008, 10:11 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jun 1999

Location: Fallbrook, CA USA,

CA

Cobra Make, Engine: Porsche 928 S4

Posts: 739

|

|

Not Ranked

Not Ranked

Nor Cal,

Be sure to check crank end play before you start taking things apart.

This can cause the problem that you are experiencing and 2k miles is about right for thrust bearings to become worn due to a number of factors.

|

07-03-2008, 11:43 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Dec 2003

Location: BAKERSFIELD,

CA

Cobra Make, Engine: KMP241 427 S/C 482 Shelby

Posts: 483

|

|

Not Ranked

Not Ranked

Norcal,,,,my former Midstates with 5 link suspention drove me crazy with the same 1st gear chatter. I won't bore you with all I did to find the problem. The fix was new, better quality heim joints at all points in the rear suspention. never another chatter as long as I had the car........Ron

__________________

RON N BKFLD

|

07-04-2008, 12:15 AM

|

|

CC Member

|

|

|

Join Date: Jan 2008

Location: Sacramento, CA,

Posts: 636

|

|

Not Ranked

Not Ranked

Hey Patrickt,

Great pics of your FE and bracket....now that is a super clean undercarriage. Outstanding!   |

07-04-2008, 05:20 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: E BRUNSWICK N.J. USA,

Posts: 3,841

|

|

Not Ranked

Not Ranked

Washes and waxes the bottom of the car

Washes and waxes the bottom of the car

|

07-04-2008, 06:05 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: E BRUNSWICK N.J. USA,

Posts: 3,841

|

|

Not Ranked

Not Ranked

Couple of ideas and my turn

Couple of ideas and my turn

NorCal Cobra. Which clutch do you have in the car? Mcleod makes 6 different setups for any motor. The pressure plates have load ranges from 2,400 lbs, to 3,800 lbs. The discs are from organic to full metal suface or pucks. Fly wheels are all steel, steel with inserts, aluminium with steel inserts that are rebuildable. As far as a bad pilot bearing, It can cause a clutch problem. Over time the trans mission as a whole will be harder to shift and the input bearing will start to whine. You might even get a little vibration in the drive train. I am hoping the the bellhousing was setup to the back of the motor and centered for runout. If not this is hard on the pilot bushing or bearing because of alignment. Mine was .038" out to start, when done I was down to .002-.003". This needs to be done and or checked before you even try to fix the clutch problem. You can build a house without a strong and solid footings under it. I am hoping your motor has not leaks and that the inside of the bellhousing is dry. If not the oil will get between the flywheel, disc, and pressure plate and over time, glaze and burn the flywheel and pressure plate faces. This will give you a hell of a chatter on takeoff in 1st gear. The only thing you might feel in the higher gears would be a little slippage on release. It's about loading the clutch. Did you break in the clutch right with normal driving? or hammer the car from the start? This will glaze the disc and cause the same chatter problem. As far as the mount of the slave cylinder, IMO it needs to be mounted on the motor and not on the frame. Pat's picture is a perfect setup of a slave system. Everything has to move or twist, if not it will snap over time.  You have twisting of the motor and the frame. For fine tuning a clutch this will not work in the racing world. I have had trucks with solid link setups, the bodies get weak and lossen over time and you start to have clutch problems. Clutch pedal stop is also needed to prevent over extendsion on the slave and bend either the fork or the pressure plate fingers of forks, depending on the pressure plate. Your clutch is junk either way and need a new one. Buy one that is going to match the car weight, amount of torque and HP, and type of driving. Street, roadracing, 1/4 drags, autocross or combo of all. Go up 1 pressure plate load range because of the car. The disc is going to be based on how well you can REALLY drive a clutch car. Ceramic or Kevlar disc over stock OEM. If you have the money, the winner is the Street twin disc if setup right. You have a soft clutch pedal and about 800HP holding power. Not CHEAP. They are quiet if setup right and you get no noise. IMO stay way from Centerforce!!!  If you want to talk about this more send a e-mail to my box or give me a call at 732-254-3536 in the evenings est time, or number to call you.There is alot more info on this also. Rick L.

|

07-04-2008, 07:47 AM

|

|

CC Member

|

|

|

Join Date: Jul 2002

Location: Greenville,sc,

SC

Cobra Make, Engine: Kirkham 427 (KMP 266); CAV GT40

Posts: 1,464

|

|

Not Ranked

Not Ranked

definitly adjust your clutch out some (more snug) that fixed mine in 5 minutes

__________________

SPF Daytona coupe 055, Roush 427R

|

07-04-2008, 07:50 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,005

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by RICK LAKE

|

Zaino is all I ever use -- water tends to leave spots.  |

09-02-2008, 03:12 PM

|

|

CC Member

|

|

|

Join Date: Nov 2003

Location: Carpentersville,

Il

Cobra Make, Engine: shell valley cobra-350 chevy

Posts: 62

|

|

Not Ranked

Not Ranked

Hey nor cal did you ever figure it out?

|

09-04-2008, 09:26 AM

|

|

CC Member

|

|

|

Join Date: Jul 2006

Location: Folsom,

CA

Cobra Make, Engine: Backdraft 427 Stroker, Sterling Gray/Silver

Posts: 68

|

|

Not Ranked

Not Ranked

Hey Rooster,

Yes and no. My slave is still attached to the frame and I have yet to fabricate a different bracket that will secure it to the tranny.

Meantime, I was able to tighten up my current setup and it helped a little. Now when I release the clutch w/ very little or no gas, the clutch chatter disappeares!!!!

Although when I go up my driveway (very steep) I get a significant amount of chatter. Once I fabricate and install my new bracket, it will definitely tell me whether or not my problem is the slave setup or the pilot bushing/pressure plate/glazed disc....etc

Thanks for asking and I'll keep ya up to date.

|

10-17-2008, 08:11 AM

|

|

CC Member

|

|

|

Join Date: Dec 2004

Location: ROCKLEDGE,

FL

Cobra Make, Engine:

Posts: 11

|

|

Not Ranked

Not Ranked

I had a similar issue . It turned out to be an oil soaked disc . I also went with a Fidanza aluminum flywheel and could not believe the difference . With these light cars you dont need that much flywheel weight and clutch pressure. |

05-14-2009, 02:33 PM

|

|

CC Member

|

|

|

Join Date: Jul 2006

Location: Folsom,

CA

Cobra Make, Engine: Backdraft 427 Stroker, Sterling Gray/Silver

Posts: 68

|

|

Not Ranked

Not Ranked

Eureka!!!!!!

I solved my clutch chatter issue. Thank you everyone for all the outstanding advice. It turns out that having the slave bolted directly to the frame was the issue all along.

I went to Lowe's and fabricated an "L" bracket from HEAVY gauge cold rolled steel. I attached the slave to the motor mount bolt via the "L" bracket and problem fixed.

It is a whole different car to drive!!!!! Now I can take advantage of that 564hp and 566 trq!!!!!

Thanks again everyone.

Mike

|

05-14-2009, 07:16 PM

|

|

CC Member

|

|

|

Join Date: Dec 2003

Location: Wilton,

CT

Cobra Make, Engine: Performance Cars Venom 427 Keith Craft 408 Stroker

Posts: 317

|

|

Not Ranked

Not Ranked

Hey Mike,

I am really happy for you. Of all the things I have ever fixed or upgraded on my car, the single most satisfying was getting rid of that clutch problem. I hope that this thread will help others as well. Anyone with a clutch slave mounted to the frame who is experiencing this problem should get a bracket that attaches to the motor mounts or the motor itself before taking apart the clutch.

__________________

If I can see you, I'm too close

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 07:37 AM.

|

I made my own mount for the third one. It is holding up fine. Another issue with some Wilwoods is that the piston unscrews from the rod. This was a part of my problem with the second one. I really believe the vibration from the two mountings you have tried could be the cause or a part of the cause of the failure and the chattering. It won't cost much to try a solid mont to the engine before embarking on a transmission & clutch removal.

I made my own mount for the third one. It is holding up fine. Another issue with some Wilwoods is that the piston unscrews from the rod. This was a part of my problem with the second one. I really believe the vibration from the two mountings you have tried could be the cause or a part of the cause of the failure and the chattering. It won't cost much to try a solid mont to the engine before embarking on a transmission & clutch removal.

He is trying a new water, top secret.

He is trying a new water, top secret.  It doesn't wet the surface but cleans and washes just the same. As you can see from the pictures it works.

It doesn't wet the surface but cleans and washes just the same. As you can see from the pictures it works.

Linear Mode

Linear Mode