Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

1 |

2 |

3 |

4 |

| 5 |

6 |

7 |

8 |

9 |

10 |

11 |

| 12 |

13 |

14 |

15 |

16 |

17 |

18 |

| 19 |

20 |

21 |

22 |

23 |

24 |

25 |

| 26 |

27 |

28 |

29 |

30 |

31 |

|

|

CC Advertisers

CC Advertisers

|

|

12-06-2009, 02:01 AM

|

|

CC Member

|

|

|

Join Date: Mar 2009

Cobra Make, Engine:

Posts: 35

|

|

Not Ranked

Not Ranked

IDA Air Flow Between Barrels Way Off?

IDA Air Flow Between Barrels Way Off?

Hello All,

Thank you for all the help so far. I finally got my IDAs running today. During the process of balancing the carburetors I noticed that the flow rate between one barrel and another barrel on the same carburetor was way off. Is this normal? What could cause this.

Thanks,

Mark

|

12-06-2009, 07:18 AM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: Portland,

OR

Cobra Make, Engine: ERA FIA, 1964 289->Webers

Posts: 3,689

|

|

Not Ranked

Not Ranked

Mine are all different. I don't know if it is 100% the way to do things but I just tried to take an avg. between the two barrels on each carb & sync them that way. My assumption, & I can't seem to find any info on this is the Butterflies in some of the barrels are letting less/more air flow past. There is an adjustment for this in some Weber Carbs, but not the 48IDAs

__________________

ERA FIA 2088

|

12-06-2009, 10:10 AM

|

|

CC Member

|

|

|

Join Date: May 2004

Location: centralia,

IL

Cobra Make, Engine: B&B cobra (sold), Hurricane HMS1002 (sold), Kirkham 289 FIA, (sold) RCR GT 40(sold) SPF GT40 2122(sold) Hurricane HMS2002, (sold) RCR SLC (sold) GTR on the way!

Posts: 1,288

|

|

Not Ranked

Not Ranked

I would suggest checking the balance just off idle when the carbs are not setting on the throttle stops. That is where it counts. They should be very close. If they aren't, it might be a result of a bent throttle shaft. If they are new, I would definately check with who you bought them through.

__________________

High Maintenance Racing Team

Run & Gun 2003 - 2013

|

12-06-2009, 10:45 AM

|

|

CC Member

|

|

|

Join Date: Mar 2009

Cobra Make, Engine:

Posts: 35

|

|

Not Ranked

Not Ranked

I thought about the bent shafts. I also thought maybe I did not get some of the butterflys back in perfectly and they are not sealing as well as others. I am having a problem getting the idle low enough also. My initial time with the Demon was 20deg with the 35deg max. Now I seem to have to back this off to get it to idle lower than 1500 rpm. This may be one of the issues as well.

Then I started thinking that with the carbs on the car there are other factors that could be impacting the flow. Valves not adjusted the same seems like it might have an impact. I have hydraulic lifters, so this seems unlikely.

I think I am going to pull them and check all the butterfly. Then mocking up a quick flow test with a vacuum to get a base like before reinstalling them. This way the car and linkage is not involved.

Thoughts??? |

12-06-2009, 10:51 AM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: Portland,

OR

Cobra Make, Engine: ERA FIA, 1964 289->Webers

Posts: 3,689

|

|

Not Ranked

Not Ranked

Let's see your fuel line setup. Where are you idle screws set? I can't imagine there being an idle problem unless there is something wrong in the fuel supply. How far off are these vacuum readings? How much fuel pressure do you have?

__________________

ERA FIA 2088

|

12-06-2009, 05:02 PM

|

|

CC Member

|

|

|

Join Date: Mar 2009

Cobra Make, Engine:

Posts: 35

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by *13*

Let's see your fuel line setup. Where are you idle screws set? I can't imagine there being an idle problem unless there is something wrong in the fuel supply. How far off are these vacuum readings? How much fuel pressure do you have?

|

I am running an in tank EFI fuel pump with a return line to the tank. This runs up to a bypass regulator with a single and AN -6 line running up to one bank and looped to the other bank. I am running 3 to 3.5 lbs pressure. Idle screws all the way out. Some are worse than others but one is 10 in one barrel and 2 in the other barrel. I am going to pull them tonight. |

12-06-2009, 05:33 PM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: Portland,

OR

Cobra Make, Engine: ERA FIA, 1964 289->Webers

Posts: 3,689

|

|

Not Ranked

Not Ranked

Wow, that is way off. Something must be wrong. I think you're on the right track. Report what you find.

__________________

ERA FIA 2088

|

12-06-2009, 05:44 PM

|

|

CC Member

|

|

|

Join Date: May 2001

Location: California,

Ca

Cobra Make, Engine: NAF 289 Slabside Early Comp Car with 289 Webers and all the goodies. Cancelling the efforts of several Priuses

Posts: 6,592

|

|

Not Ranked

Not Ranked

Is the general condition of the engine favorable? Valve seats good?

__________________

Rick

As you slide down the Banister of Life, may the splinters never be pointing the wrong way

|

12-06-2009, 05:53 PM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Cobra Make, Engine:

Posts: 177

|

|

Not Ranked

Not Ranked

Thats normal, there is an air bypass adjustment screw on the outside of the carb with a lock nut. You should be able to balance the carb with that screw.

I have seen some aftermarket weber carbs (non ferrari) that do not have these scews. Hope you have them, they should be near the idle screws.

|

12-06-2009, 06:07 PM

|

|

CC Member

|

|

|

Join Date: May 2001

Location: California,

Ca

Cobra Make, Engine: NAF 289 Slabside Early Comp Car with 289 Webers and all the goodies. Cancelling the efforts of several Priuses

Posts: 6,592

|

|

Not Ranked

Not Ranked

Racco not on IDA's. It would be a welcome addition but these were originally competition carburetors and consequently they were deemed unnecessary.

__________________

Rick

As you slide down the Banister of Life, may the splinters never be pointing the wrong way

|

12-06-2009, 06:10 PM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Cobra Make, Engine:

Posts: 177

|

|

Not Ranked

Not Ranked

I just rebuilt a set of three ida's on a lancia stratos and the bypass screws were there. But I have seen aftermarket or replacement webers without them.

|

12-06-2009, 06:14 PM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: Portland,

OR

Cobra Make, Engine: ERA FIA, 1964 289->Webers

Posts: 3,689

|

|

Not Ranked

Not Ranked

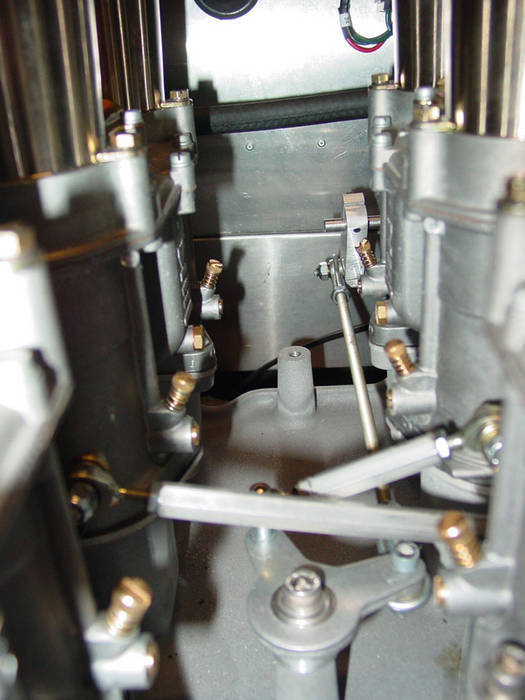

My Ida's do not. This is what we see. I'm under the belief that the Idle jet carrier needs to be replaced to get more air flow?

__________________

ERA FIA 2088

Last edited by *13*; 12-06-2009 at 06:20 PM..

|

12-06-2009, 06:16 PM

|

|

CC Member

|

|

|

Join Date: Feb 2007

Location: Scottsdale,

Az

Cobra Make, Engine: ERA FIA #2119

Posts: 310

|

|

Not Ranked

Not Ranked

this is from the Ingelese site;

For the sake of simplicity, let's look at the Weber carburetor as having three basic circuits- the idle circuit, the accelerator pump circuit and the main circuit.

The idle circuit is comprised of two components, the idle jet and the idle jet carrier. With these two pieces, the tuner can select exactly how much fuel and how much air he wants to provide the engine at idle and during the low rpm operation, while making very fine adjustments to either, if necessary. The idle mixture is delivered as a proportioned mixture whose total volume can be further regulated with the idle mixture screw, which is located on the lower part of each carburetor barrel. On a correctly-jetted idle circuit, the mixture screw on a 48 IDA is never more than 3/4 of a turn out. This will hold true 100% of the time, no matter what anyone else tells you. If you have to go more than that, you'd better heavy-up the idle jet. Even if you get it to idle, going more than 3/4 turn tells you the jet is lean and you're going to have other drivability problems, which brings us to the next part of the idle jet's function.

The idle circuit in the Weber isn't just an idle circuit - it does more than that. It is actually the circuit which must carry the engine all the way up to about 2,800-3,000 rpm, where the transition to the main circuit take place. That means if you don't drive over 3,000 rpm, you're only running on the idle jets. After 3,000 rpm or so, the idle circuit is entirely bypassed and no longer has anything to announce. So, if you have a tuning problem that "goes away" after about 3,000 rpm, that tells you to play with the idle circuit. Or maybe the opposite is true. Either way, it's very cut and dried as far as the two circuits are concerned - so isolating the problem is a breeze.

One the most frequently experienced "gremlins" with Weber carburetors is a seemingly incurable and very annoying flat spot which rears its ugly head at about 2,200-2,800 rpm. This condition is generally caused by one of two things - you either have the wrong emulsion tube in the carburetor, which is causing a rich stumble due to an under-emulsified mixture at that particular rpm range or the idle circuit is falling off too early to carry the engine up to the point where the main circuit can take over, leaving a "lean hole". In simple terms, the idle circuit is going lean too early. Either condition is easily rectified. In the case of the emulsion tube, there are really only a few which work really well for V8 applications; and if you aren't using one of them it is certainly a big part of the problem. If the flat spot is still there even with the correct emulsion tube, then you'll need to richen up the idle circuit. This is sometimes a tricky area, because the first thing you want to do is throw in a bigger idle jet, but sometimes playing with air bleeds, mixture screws, or choke sizes can accomplish the same thing while sticking with the original jet size. Seeking a little bit of sound advice here can save a lot of time and hassle. The point here is that these carburetors are designed to come off idle and run smoothly all the way up. Your problems can be solved with a little tuning on your own or by relating the symptoms to someone who is knowledgeable enough to help you. Remember, these carburetors will do just about anything you want them to, except maybe wash your socks.

The accelerator pump circuit, just like on any carburetor, is responsible for eliminating "bog" and making a passing maneuver without a hesitation or stumble. The circuit also has two basic elements. These are the pump exhaust valve and the pump jet. The pump exhaust is nothing more than a bypass valve and this is located in the bottom of the float bowl. This is the piece that regulates how much fuel you want to make available when you need that pump shot. Putting a bigger bypass hole in the valve allows more fuel to bleed back into the float bowl instead of out of the shooters. The smaller the hole, the more fuel you're making available. You can even put in a "closed" bypass for drag racing, when you need all the juice you can get in order to get those slicks turning. Obviously, there is nothing complicated about a simple bypass system. The duration of the pump shot is varied by installing a larger or smaller pump jet (shooter). Larger pump jets give a heavy blast over a short period, while the smaller ones will give a finer, longer-duration shot. As long as you leave the bypass valve alone, you're still getting the same overall volume. In most cases, the stock pump jets can be left alone.

Don't know it helps but is a great article.

|

12-06-2009, 06:22 PM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Cobra Make, Engine:

Posts: 177

|

|

Not Ranked

Not Ranked

I have been servicing and restoring ferrari's for twenty years and they all have them, even a riva ferrari boat that I rebuilt the ida's (eight in total) on two btm engines and they had them. You may have to drill a hole in the trottle plate of the carb with the lower draw reading or if the carbs are old and the throttle shafts are worn the venturi body may be worn and the air is bypassing the throttle plate. If the body is worn the carb may be srcap

|

12-06-2009, 06:26 PM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Cobra Make, Engine:

Posts: 177

|

|

Not Ranked

Not Ranked

idle jet controls fuel flow not air flow.

|

12-06-2009, 06:29 PM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: Portland,

OR

Cobra Make, Engine: ERA FIA, 1964 289->Webers

Posts: 3,689

|

|

Not Ranked

Not Ranked

There is no other adjustment on the bottom of the carb. This may be a newer development in the 48IDA. I bought mine new a few years back. I wish there was. Would be nice to be able to adjust the air.

__________________

ERA FIA 2088

|

12-06-2009, 06:36 PM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Cobra Make, Engine:

Posts: 177

|

|

Not Ranked

Not Ranked

that adjustment will make the car idle so much smoother that it will now with the idle number all over the place. Which air flow gauge are you using?

|

12-06-2009, 06:40 PM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: Portland,

OR

Cobra Make, Engine: ERA FIA, 1964 289->Webers

Posts: 3,689

|

|

Not Ranked

Not Ranked

Just the Vacuum in the horn Gauge. It's pretty consistent. I hear the older versions were terrible. My car Idles fine. The barrels aren't off by much. Being nit picky, I'd like to see them exactly even though.

__________________

ERA FIA 2088

|

12-06-2009, 06:46 PM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Cobra Make, Engine:

Posts: 177

|

|

Not Ranked

Not Ranked

Get yourself the air flow gauge from pierce manifolds it looks like a snail shell (dont recall the brand name) and it sits in the barrel. It will give you exact readings. These cars have very lumpy idles and it may be difficult to notice if the balance is off. On a ferrari you can hear it from ten feet away.

|

12-06-2009, 07:11 PM

|

|

CC Member

|

|

|

Join Date: May 2001

Location: California,

Ca

Cobra Make, Engine: NAF 289 Slabside Early Comp Car with 289 Webers and all the goodies. Cancelling the efforts of several Priuses

Posts: 6,592

|

|

Not Ranked

Not Ranked

racco- The Idle air bleeds are OEM on the 40/42/46 IDA 3C Weber (3bbl) Carb used on Porsche and on some other applications (perhaps Ferrari as well). They have never been a part of the 48IDA 2bbl. The bodies do not have any undrilled bosses that could be utilized. Is it possible you have this carb confused with the IDF speced for the Lancia Stratos V6 Dino engine, they DO have the air bleed in question.

__________________

Rick

As you slide down the Banister of Life, may the splinters never be pointing the wrong way

Last edited by Rick Parker; 12-06-2009 at 07:29 PM..

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 01:15 PM.

Links monetized by VigLink

|