06-16-2014, 08:48 PM

|

|

CC Member

|

|

|

Join Date: Jan 2008

Location: Williamsport,

PA

Cobra Make, Engine: Kellison Stallion 468 FE

Posts: 2,703

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by PaulProe

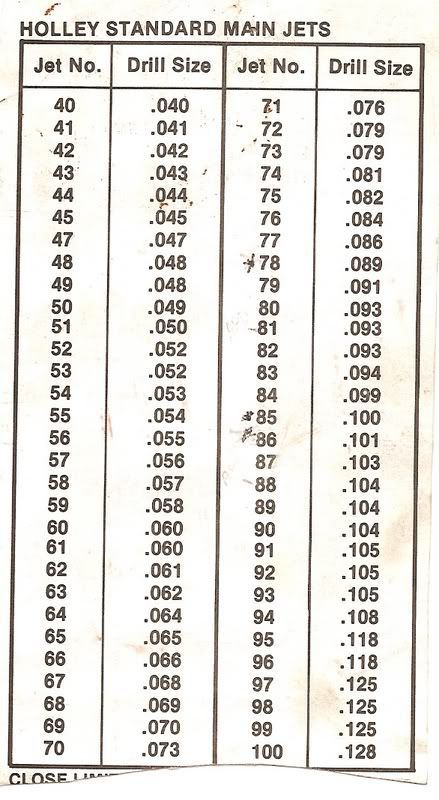

A number of questions on the practice of drilling jets/holders/correctors

- I have a number of jets I obtained from a friend who has, in the past, drilled jets till he found what he liked, then ordered a set of replacements at that size. The jets he lent me, I don't know if they've been drilled or not. Example is an idle jet market 55F10. But a .60 mm drill will go thru it with just a very slight drag. The drill shank actually measures .565mm. the $1000 question, is the jet actually a 55 or is it a 60?

- Does anyone know the typical undersize amount a drill is from the hole it is supposed to drill. ie, if it is a .60mm drill, what should the bit shank actually measure? I know the drills will drill just slightly larger than the shank, but I don't know how much

- Does everyone agree it is an acceptable practice to drill holders or correctors since they are passing air and not as flow critical as jets?

- Is there a way to definitively tell if a jet has been drilled or not. Obviously, if it is marked 150 and it passes a 170 drill, but what about those that are just a few thousands oversize?

Thanks

Paul |

more to a jet than just its orifice size there are entry and exit differences.

personally any used jet that has been drilled, i would call trash

__________________

Fred B

|