Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

|

1 |

| 2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 9 |

10 |

11 |

12 |

13 |

14 |

15 |

| 16 |

17 |

18 |

19 |

20 |

21 |

22 |

| 23 |

24 |

25 |

26 |

27 |

28 |

29 |

| 30 |

31 |

|

|

|

|

|

|

CC Advertisers

CC Advertisers

|

|

5Likes 5Likes

04-14-2007, 01:51 PM

|

|

CC Member

|

|

|

Join Date: Jun 2003

Location: Palma de Mallorca, Spain,

ESP

Cobra Make, Engine: Contemporary with 482 KC/SO, TKO600,IRS Jag/AMP, 3.54 Salisbury PL,

Posts: 582

|

|

Not Ranked

Not Ranked

Brent,

my last drive during a rally was with this setup on the 48 IDAs:

Main venturi 40mm

Third progression hole drilled (might not be necessary)

Idler jet 65

Idle screw 1 turn out (3/4 turn only would produce too much exhaust popping)

Idle holder 100 ( the 60 holder was too rich at cruising speeds at 2000 rpm )

Main jet 150 ( with smaller jet it would lean out at WOT in 4th gear at 6000rpm)

Air Corrector 120 (larger air correctors would lean out the mixture too much at WOT)

Emulsion tube very similar to F14.

Its actually a F7 modified tube with no holes in the bottom part but only at the top. So you get aireation during the low transition (holes on top), thus leaning out there, and no holes at the bottom, which produces less aireation at the high transition band, thus richening the mixture until the main jet takes over from there.

Pump bypass 00 (would bog down with a .50 when stepping on the gas suddenly).

The car ran fantastic with this. Maybe I should try a .35 pump bypass because the sidepipes were showing black smoke when accelerating.

Finally I think I have understood how the webers work. Testing the car after every minor change and writing the result and the reading from the lambda sensor down showed some patterns. All the changes I made overlap to some degree, so I had to try all the different combinations.

Basically the changes going up the rpm scale are influenced in this order:

idle jet - idle air corrector - emulsion tube outer and inner diameter - holes on top - holes at the bottom - main jet - main air corrector , while the emulsion tube and main jet overlap in its influence and are the ones affecting the transition the most.

The light tan color of the spark plugs confirms that the mixture is now almost perfect.

But all this was only possible after I changed the main venturi to 40mm inner diameter.

With the 37mm chokes things never worked right, and the plugs were allways black, which means too rich mixture all over.

What the 37mm choke/F5-F7 emus.tube/60 air corr./ setup was doing is overly richening the transition over a broad band to go over the stumble.You are effectively pouring gasoline all over to get one spot right.

And here is a hint from Inglese in their technical primer: (giving away some crucial information btw)

Pull out those small chokes, drop in some large-diameter ones, which may be nothing more than thin-wall "sleeves", and you've got a set of 48 IDA's that will flow enough CFM to make a big block scream.

All said.

Stefan

__________________

Nothing sounds better than a Cobra in a Tunnel !

|

04-14-2007, 02:02 PM

|

|

CC Member

|

|

|

Join Date: Jul 2002

Location: Greenville,sc,

SC

Cobra Make, Engine: Kirkham 427 (KMP 266); CAV GT40

Posts: 1,464

|

|

Not Ranked

Not Ranked

Stefan, I think you would need to go with a 55 bypass not 35 to decrease the over rich mixture. A 55 puts less fuel to the pump jet than a 50, is how I understand it. chuck

|

04-14-2007, 03:22 PM

|

|

CC Member

|

|

|

Join Date: Jun 2003

Location: Palma de Mallorca, Spain,

ESP

Cobra Make, Engine: Contemporary with 482 KC/SO, TKO600,IRS Jag/AMP, 3.54 Salisbury PL,

Posts: 582

|

|

Not Ranked

Not Ranked

Chuck,

I have a 00 bypass now, not a 0.50. That means no bypass at all. The 0.50mm bypass was creating a bog, the 0.00 is good, but gives black smoke.

So a 0.35mm hole bypass is more than 00 but about 50% less than a 0.50 bypass. That should hopefully do away with the black smoke without creating a bog. Otherwise I will have to keep the 00 bypass and try something else.

Stefan

__________________

Nothing sounds better than a Cobra in a Tunnel !

|

04-14-2007, 03:41 PM

|

|

CC Member

|

|

|

Join Date: Jul 2002

Location: Greenville,sc,

SC

Cobra Make, Engine: Kirkham 427 (KMP 266); CAV GT40

Posts: 1,464

|

|

Not Ranked

Not Ranked

got it. chuck

|

04-14-2007, 03:43 PM

|

|

CC Member

|

|

|

Join Date: Jul 2002

Location: Greenville,sc,

SC

Cobra Make, Engine: Kirkham 427 (KMP 266); CAV GT40

Posts: 1,464

|

|

Not Ranked

Not Ranked

I wonder if smaller pump jets would help. The same amount of fuel is jetted but over a longer period of time. decisions ,decisions. chuck

|

04-14-2007, 03:45 PM

|

|

CC Member

|

|

|

Join Date: Jul 2002

Location: Greenville,sc,

SC

Cobra Make, Engine: Kirkham 427 (KMP 266); CAV GT40

Posts: 1,464

|

|

Not Ranked

Not Ranked

by the way ,my wifes sister lives in Seville, are you near there?

|

04-14-2007, 04:36 PM

|

|

CC Member

|

|

|

Join Date: Jun 2003

Location: Palma de Mallorca, Spain,

ESP

Cobra Make, Engine: Contemporary with 482 KC/SO, TKO600,IRS Jag/AMP, 3.54 Salisbury PL,

Posts: 582

|

|

Not Ranked

Not Ranked

chuck,

with four webers you have 4 pump bypasses and 8 pump jets. So I would first try to tune with the 4 bypasses instead of the 8 jets, which btw also cost more.

But I have to wait to do that until I have my engine repaired.

Not very inclined at this moment to get the engine out. Feeling quite lazy lately.

I live in Mallorca, which is part of the Balearic Islands right in the middle of the Mediterranean Sea. Sevilla is on the Mainland down south. Maybe 1.5 hours by plane. Not too far away if you compare with distances like NY to LA.

Stefan

__________________

Nothing sounds better than a Cobra in a Tunnel !

|

04-14-2007, 10:54 PM

|

|

Administrator

|

|

|

Join Date: Jan 1999

Location: Duvall,

Wa

Cobra Make, Engine: KMP286, Shelby 482, Webers, 593HP

Posts: 4,162

|

|

Not Ranked

Not Ranked

Quote:

|

Originally Posted by Eljaro

Brent,

my last drive during a rally was with this setup on the 48 IDAs:

Main venturi 40mm

Third progression hole drilled (might not be necessary)

Idler jet 65

Idle screw 1 turn out (3/4 turn only would produce too much exhaust popping)

Idle holder 100 ( the 60 holder was too rich at cruising speeds at 2000 rpm )

Main jet 150 ( with smaller jet it would lean out at WOT in 4th gear at 6000rpm)

Air Corrector 120 (larger air correctors would lean out the mixture too much at WOT)

Emulsion tube very similar to F14.

Its actually a F7 modified tube with no holes in the bottom part but only at the top. So you get aireation during the low transition (holes on top), thus leaning out there, and no holes at the bottom, which produces less aireation at the high transition band, thus richening the mixture until the main jet takes over from there.

Pump bypass 00 (would bog down with a .50 when stepping on the gas suddenly).

The car ran fantastic with this. Maybe I should try a .35 pump bypass because the sidepipes were showing black smoke when accelerating.

Finally I think I have understood how the webers work. Testing the car after every minor change and writing the result and the reading from the lambda sensor down showed some patterns. All the changes I made overlap to some degree, so I had to try all the different combinations.

Basically the changes going up the rpm scale are influenced in this order:

idle jet - idle air corrector - emulsion tube outer and inner diameter - holes on top - holes at the bottom - main jet - main air corrector , while the emulsion tube and main jet overlap in its influence and are the ones affecting the transition the most.

The light tan color of the spark plugs confirms that the mixture is now almost perfect.

But all this was only possible after I changed the main venturi to 40mm inner diameter.

With the 37mm chokes things never worked right, and the plugs were allways black, which means too rich mixture all over.

What the 37mm choke/F5-F7 emus.tube/60 air corr./ setup was doing is overly richening the transition over a broad band to go over the stumble.You are effectively pouring gasoline all over to get one spot right.

And here is a hint from Inglese in their technical primer: (giving away some crucial information btw)

Pull out those small chokes, drop in some large-diameter ones, which may be nothing more than thin-wall "sleeves", and you've got a set of 48 IDA's that will flow enough CFM to make a big block scream.

All said.

Stefan

|

Thanks Stefan! I have an LM-1 too. I am finding that I'm going lean just before the transition and was looking for 100 idle holders but hit a dead end with Pierce manifolds and Inglese. Sounds like you made some good headway there with your transition...Do you have a line on who has them?

I'm running:

160 Idles

120 holders

165 mains

F7

210 corrector

37 chokes (will try the 40's)

I think 50s on the pump bypass

If I give a little throttle to get through that flat spot during transition, then hang on!!!! I'm hoping the 100 holders help with that lean spot. |

04-15-2007, 12:57 AM

|

|

CC Member

|

|

|

Join Date: Jun 2003

Location: Palma de Mallorca, Spain,

ESP

Cobra Make, Engine: Contemporary with 482 KC/SO, TKO600,IRS Jag/AMP, 3.54 Salisbury PL,

Posts: 582

|

|

Not Ranked

Not Ranked

IDA idle holders

IDA idle holders

Brent,

I got my idle holders from VGS Motorsport in Koeln, Germany.

You can contact boetel@vgs-tuning.de

The part you need is 77093.100.

You can also plug the 1.2mm hole on your holders and drill a 1mm one instead.

You can always drill the 1mm one back to 1.2mm if you do not like it.

Stefan

__________________

Nothing sounds better than a Cobra in a Tunnel !

|

04-15-2007, 05:10 AM

|

|

CC Member

|

|

|

Join Date: Feb 2007

Cobra Make, Engine:

Posts: 10

|

|

Not Ranked

Not Ranked

WIth all this tech. I'm glad you got the Weber and I got a double pumper.

|

04-15-2007, 06:23 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Oct 1999

Location: Menomonie, Wisconsin,

Posts: 3,505

|

|

Not Ranked

Not Ranked

Actually, the third progression hole will go a long way to helping you to correcting a bad transition phase. The VW people have known this trick for years. If you trouble is transition, try drilling out the third hole. It will save you a lot of time and money---and frustration. If you problems are other than transition, the third hole is not the answer.

Webers are a great system, but....bubbagump does have a point.

|

04-15-2007, 07:23 AM

|

|

CC Member

|

|

|

Join Date: Jul 2002

Location: Greenville,sc,

SC

Cobra Make, Engine: Kirkham 427 (KMP 266); CAV GT40

Posts: 1,464

|

|

Not Ranked

Not Ranked

Do you know anyone who does the drilling of the third progression hole?

|

04-15-2007, 10:16 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Oct 1999

Location: Menomonie, Wisconsin,

Posts: 3,505

|

|

Not Ranked

Not Ranked

A friend of mine who I crewed with on the OY 2 team has a friend in L.A. who developed a simple jig by using the plug that is tapped into the progression hole. I do not have his name but could probably get it.

|

04-15-2007, 11:08 AM

|

|

Administrator

|

|

|

Join Date: Jan 1999

Location: Duvall,

Wa

Cobra Make, Engine: KMP286, Shelby 482, Webers, 593HP

Posts: 4,162

|

|

Not Ranked

Not Ranked

Quote:

|

Originally Posted by Cal Metal

Actually, the third progression hole will go a long way to helping you to correcting a bad transition phase. The VW people have known this trick for years. If you trouble is transition, try drilling out the third hole. It will save you a lot of time and money---and frustration. If you problems are other than transition, the third hole is not the answer.

Webers are a great system, but....bubbagump does have a point.

|

Does that essentially richen the mixture? |

04-15-2007, 03:07 PM

|

|

CC Member

|

|

|

Join Date: Jun 2003

Location: Palma de Mallorca, Spain,

ESP

Cobra Make, Engine: Contemporary with 482 KC/SO, TKO600,IRS Jag/AMP, 3.54 Salisbury PL,

Posts: 582

|

|

Not Ranked

Not Ranked

I did drill the third progression holes myself.

First I marked the position inside the access to the progression holes(forming a triangle with the two existing holes) with a thin sharp pointed tool. Once I got the mark correctly positioned I marked it stronger with a light hammer blow (which aids in guiding the fine 1mm drill bit) I used a dremel hand drill with a 1mm bit to make the holes. It requires a steady hand and keeping the 90º angle of the drill in relation to the carb bore. Otherwise not much more.

Check out this link, which is where I got the instructions from on how to do it:

http://www.aircooled.net/gnrlsite/re...idarebuild.htm

Good luck!

__________________

Nothing sounds better than a Cobra in a Tunnel !

|

04-15-2007, 03:09 PM

|

|

CC Member

|

|

|

Join Date: Sep 2000

Location: Brownsville,

CA.

Cobra Make, Engine: Superformance, #930, 351W/427CID 419 RWHP (before the Webers!)

Posts: 224

|

|

Not Ranked

Not Ranked

Pierce Manifolds in Gilroy, Ca. will drill the third hole in your 48IDAs.

__________________

Terry Brown SPF #930 427W 419 RWHP 48 IDA Webers

"Remember, your car will not be more valuable after Track Day than it is the day before the event" - Eric W. instructional presentation on Track Day safety, 05/15/2008 WSCB

|

04-17-2007, 07:58 PM

|

|

Administrator

|

|

|

Join Date: Jan 1999

Location: Duvall,

Wa

Cobra Make, Engine: KMP286, Shelby 482, Webers, 593HP

Posts: 4,162

|

|

Not Ranked

Not Ranked

I think I'm going to try and drill the holes myself this weekend. Kinda scary, but what the hell, I need to take the carbs off anyway to put on the phenolic spacers I got. Eljaro, thanks for the pointer to the instructions. That was really helpful.

One other thing I am noticing is that when cornering, I get a stumble. I'm guessing that my floats need adjusting. I haven't been able to find much in the way of explanations on how to make this adjustment. I see the pics on that site where the thrid progression hole is shown, but there's not much detail there on the subject.

|

04-17-2007, 08:18 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Oct 1999

Location: Menomonie, Wisconsin,

Posts: 3,505

|

|

Not Ranked

Not Ranked

Brent:

Email me with your phone number and I can tell you how to adjust the floats.

Cal Metal

|

04-18-2007, 06:55 AM

|

|

CC Member

|

|

|

Join Date: Jun 2003

Location: Palma de Mallorca, Spain,

ESP

Cobra Make, Engine: Contemporary with 482 KC/SO, TKO600,IRS Jag/AMP, 3.54 Salisbury PL,

Posts: 582

|

|

Not Ranked

Not Ranked

Brent,

I have adjusted my floats at 4.2mm top of float (not the rim) to the lower body surface. I use this self made tool to adjust the height.

This plate ,  with a screw in the center hole holded by two nuts , and with the tip of the screw pointed and rounded and set at 25.5mm from the bottom of the plate surface will be the stop which the tang of the float will hit. You pull the float up by using a fine bent wire and pull it up from one side.

I use this tool  to bend the tang without removing the float from the carb.

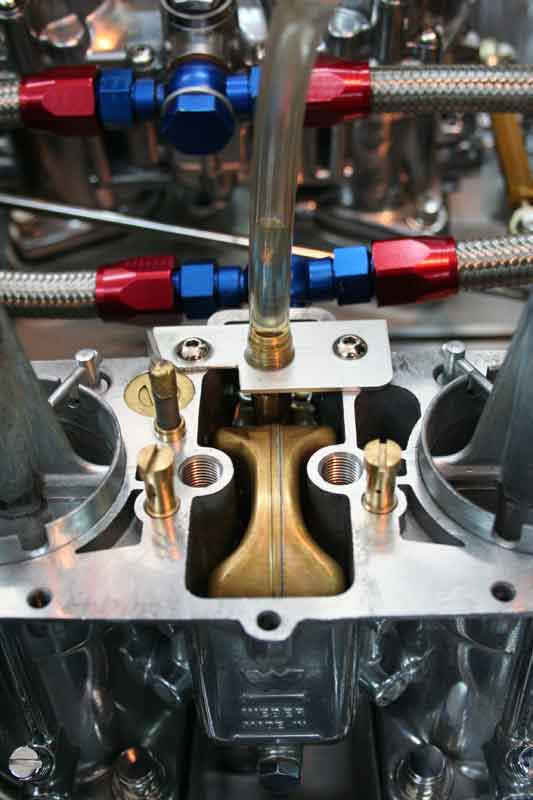

Here is how it looks like (forget the tube coming in from above, that was an experiment with gasoline and a needle valve)

Hope this helps.

Stefan

__________________

Nothing sounds better than a Cobra in a Tunnel !

|

05-03-2007, 06:14 PM

|

|

CC Member

|

|

|

Join Date: Jul 2002

Location: Greenville,sc,

SC

Cobra Make, Engine: Kirkham 427 (KMP 266); CAV GT40

Posts: 1,464

|

|

Not Ranked

Not Ranked

Well , I put the 40mm chokes in today and the car runs really well. I see no downside to them. The low speed manners are unchanged and the high speed performance is unbelievable. I really think 42's would be ok. I have not changed any jetting yet so after I hook up the LM-1 I will make a few changes most likely. I definitly am getting less black smoke and the plugs are not as sooty so far. If you think about it this all makes sense. How can the same chokes that typically are run on 302 cars possibly big enough for a 427(in my case 454)? I think Stefan has hit on something. Now if I could come up with a better emulsion tube.

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 02:24 AM.

Links monetized by VigLink

|