Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

1 |

2 |

| 3 |

4 |

5 |

6 |

7 |

8 |

9 |

| 10 |

11 |

12 |

13 |

14 |

15 |

16 |

| 17 |

18 |

19 |

20 |

21 |

22 |

23 |

| 24 |

25 |

26 |

27 |

28 |

29 |

30 |

|

CC Advertisers

CC Advertisers

|

|

02-28-2009, 09:13 AM

|

|

CC Member

|

|

|

Join Date: Mar 2004

Cobra Make, Engine: spf 2112 *427 stroker windsor

Posts: 333

|

|

Not Ranked

Not Ranked

Priobe;

My engine is a 351 based 427 stroker.

|

03-01-2009, 05:31 PM

|

|

CC Member

|

|

|

Join Date: Nov 2008

Cobra Make, Engine:

Posts: 2

|

|

Not Ranked

Not Ranked

I have a 428FE with 48IDA's on a straight cut manifold that boils fuel, too. The only carb that drips is the #5 & #6 cylinders. This carb gets the fuel first from the pump. The fuel boils up the E tube and drips out the main circuti on to the throttle plates. If you remove the E tube, the dripping will stop. I stuck a small thermometer probe into the E tube hole, into the boiling fuel. The tem is only 130 degrees. I then used a laser thermometer on the outside of the fuel bowl - same temp 130 degrees. I don't understand why the fuel is boiling at 130 degrees. Maybe it's the additives or Ethanol from today's fuels. Any ideas?

AFR

My 428 idles at 12.7 to 13.0. The motor will not tolerate anything leaner than that. I can cruise about 13.5; the motor runs well there.

|

03-02-2009, 07:17 AM

|

|

CC Member

|

|

|

Join Date: Mar 2004

Location: miami,

FL

Cobra Make, Engine: E-M Cobra Ford FE 427 w/ Webers 48 IDA

Posts: 1,380

|

|

Not Ranked

Not Ranked

Well I guess this proves it has nothing to do with the canted intakes.

mfarrell,

I have suspected that it might be today's fuels also. However I have not yet tried it.

I too used a laser on my carb body with a result of 150 degrees.

However, listed above I have mentioned what I did to help "my" situation.

Lowering the fuel does help alot. Also getting away from the oo bypass will definitly help in this situation. To counter act the 00 bypass you will have to change your emulsion tube, again in "my situation"

Just curious, what are is your jetting?

|

03-02-2009, 08:37 AM

|

|

CC Member

|

|

|

Join Date: Dec 2007

Location: Newnan,

GA

Cobra Make, Engine: ERA 723 Shelby 482

Posts: 124

|

|

Not Ranked

Not Ranked

Reid Vapor Pressure

Reid Vapor Pressure

I copied this from a site on CC. I think it explains vapor lock and the boiling in carbs.

Brent

Tech Tips from Walt

TECH TIPS FROM THE

“OLE KOOTER”

Colorado Hot Fuel Problem

Let’s Talk Fuels

The problem at this time and altitude in Colorado

Here in Colorado at high altitude, we can experience several types of fuel-related problems in carbureted engines. The higher the altitude, the worse the problems are. One is vapor lock where gasoline vaporizes from heat in the fuel line, thereby starving the engine for fuel. The other is the heat soak/ hot start/run problem.

When a hot engine is turned off, heat builds up in the engine compartment. This causes fuel to rise in the carburetor bowl and drip down from the venturi boosters into the engine. The engine is now flooded and is hard to start.

The next is what we call “geysering” and happens on a running engine. The elevated temperature of the pressurized fuel in the line entering the carb bowl past the needle and seat causes the fuel to boil violently. The drop in pressure from the line to atmospheric in the bowl causes this. The fuel “geysers” up out of the bowl vent tube.

There are two times of the year when these problems are greatest for our carbureted engines. One is in the late fall and the other is in the early spring. These are periods where winter fuels are in use but summer temperatures can be present. This is because winter fuels boil at lower temperatures than summer fuels. The problem is worsened as the vehicle goes up in altitude, because the boiling temperature of gasoline, just like water, goes down as the altitude is increased.

Unlike injected engines, carbureted engines have the fuel at ambient pressure in the carb bowl before entering the engine. Remember, the higher the fuel pressure, the higher the boiling temperature. The fuel is under pressure up to the carb. But, once the fuel passes the needle & seat into the bowl, it is at ambient pressure. Here is where we experience violent vaporization or boiling. We even see it geyser up out of the bowl vent tube. But if we cool the bowl with a damp cool rag the problem stops immediately. The fuel bowl doesn’t even feel hot when this problem occurs. This tells us that the boiling temperature at this altitude for the fuel is just a little above ambient. So if we subject it to summer temperatures, the problem occurs. It all has to do with fuel volatility.

Volatility is a measure of the gasoline’s tendency to vaporize under a given set of conditions. Reid Vapor Pressure (RVP) is a commonly used indicator of gasoline volatility. Boiling is a violent version of vaporizing. The higher the RVP, the greater the tendency to vaporize or vapor lock.

We don’t have this problem with our race gas on the hottest days in the middle of the summer. So let’s look at RVP. Our 110-octane race gas that we blend down has a RVP of 6.6pounds per square inch (psi). Our summer unleaded 91-octane gas that blend with race gas to lower the octane of the race gas with has an RVP of about 9psi. That is if all the remaining winter gas has been used up from the gas station’s tank.

This is because the RVP changes during the year. The summer gas delivered from the refinery has the 9psi RVP from mid April to mid September. After September, it starts to rise monthly till it gets to a max in December & January of about 15psi. Then it starts coming down again till April. The higher the RVP, the lower the boiling temperature. The addition of ethanol can also lower the boiling temperature.

So why does the gas from some stations boil worse than from others? If the April gas is in the tank truck but there is still some March gas in the station tank, the gas you get will have a RVP higher than the 9psi for April through summer.

If you don’t run a fuel with a low RVP, the best thing to do if the vehicle has been running hard and is shut down for a while is to open the hood to let the hot air out of the engine compartment. If the vehicle is prone to geyser while running, like at high altitude climbing up to the Eisenhower Tunnel, a simple method, that may sound rinky-dink, but really works, is to carry a cold wet towel and put it around the carb bowls when the problem occurs. This works every time on our dyno at 7500-foot elevation. Following is a chart of RVP classes and which is in use at different times of the year. These apply for Colorado.

Class RVP Max 10% Boiling Temp F 50% Boiling Temp F

Class A 9 158 170 to 250

Class B 10 149 170 to 250

Class C 11.5 140 170 to 250

Class D 13.5 131 150 to 250

Class E 15 122 150 to 245

Ethanol raises the RVP about 1 psi.

Blend by month: Jan E Feb E-D Mar D-C April C-A May thru Sept15 A Oct B-C Nov C-D Dec D-E

A worse case would be a very warm day in January when the fuel starts to boil at 122deg or lower with ethanol.

Insulating lines and carburetor will help buy time till the problem occurs and may solve the problem in marginal cases. Replacing a mechanical fuel pump on the engine with an electrical pump close to the fuel tank can reduce the fuel line vapor lock problem. The mechanical pump acts as a heat source. Hot fuel with vapor can be pushed much easier than pulled as an up front pump does.

In a nutshell, cool the fuel or raise it’s boiling temperature.

Happy motoring.

|

03-02-2009, 11:16 AM

|

|

CC Member

|

|

|

Join Date: Mar 2004

Location: miami,

FL

Cobra Make, Engine: E-M Cobra Ford FE 427 w/ Webers 48 IDA

Posts: 1,380

|

|

Not Ranked

Not Ranked

hmmm,

I wonder if this might explain why I dont remember having this problem.

Also, I guess if I switch to higher Octane with no Ethanol I might not have this problem

|

03-02-2009, 01:36 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: May 2007

Location: San Clemente,

CA

Cobra Make, Engine: CSX 4758, CSX 381 Keith Craft 482 w/ Weber 48 IDA's

Posts: 492

|

|

Not Ranked

Not Ranked

priobe,

I've been reading this and other threads on the sidelines feeling your frustration. I am just embarking on almost what sounds to be a similar setup to yours....with the exception of the cam, which is a little more lopey (252-262 duration with .622-.622 lift). Also a KC 482 formula engine.

I started my car for the first time yesterday with the 10 degree Webers, and after initial settings and valve adjustments, shut it down and experienced the dripping. A lot of dripping that pooled onto the throttle blades. So basically you lowered the fuel level, changed to an F11 E-tube, and the bypass change didn't have any effect.

Can you give us your jets, corrector, and other specs on the carbs that finally seem to be working for you and not give you the popping from a lean condition on decel or cruise. The Webers are great and this tuning stuff is what makes them really fun. Not to mention the throttle response. WOW!Thank you.

Tom

|

03-02-2009, 01:54 PM

|

|

CC Member

|

|

|

Join Date: Mar 2004

Location: miami,

FL

Cobra Make, Engine: E-M Cobra Ford FE 427 w/ Webers 48 IDA

Posts: 1,380

|

|

Not Ranked

Not Ranked

rokndad,

Actuallythe changes I have made have made a difference for the better. The bypass made the best improvement.

How ever here is my carb setup:

120 holder

65 idle jet

210 air corrector

F2 emulsion tube

150 main

55 bypass

Float level at .220 in

I ran that same cam you are describing with more lift 680 114 lope separation and it ran great !!!

I have changed my cam to a 245/250 660 lift 112 lsa because cam motion felt this was the better of the 2 cams. Honestly I am still undecided which cam is better. I figured I could always do a cam swop since you really don have to remove the intake (have not tried it but looks doable)

Check your PM

|

03-05-2009, 06:20 PM

|

|

CC Member

|

|

|

Join Date: Nov 2008

Cobra Make, Engine:

Posts: 2

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by priobe

Well I guess this proves it has nothing to do with the canted intakes.

mfarrell,

I have suspected that it might be today's fuels also. However I have not yet tried it.

I too used a laser on my carb body with a result of 150 degrees.

However, listed above I have mentioned what I did to help "my" situation.

Lowering the fuel does help alot. Also getting away from the oo bypass will definitly help in this situation. To counter act the 00 bypass you will have to change your emulsion tube, again in "my situation"

Just curious, what are is your jetting?

|

40mm venturi

idle jet is 60

idle jet holder 120

e-tube f2

main jet 155

air corrector 220

accelerator pump valve 60

pump jet size 50

float height 5.5 mm |

03-05-2009, 07:23 PM

|

|

CC Member

|

|

|

Join Date: Mar 2004

Location: miami,

FL

Cobra Make, Engine: E-M Cobra Ford FE 427 w/ Webers 48 IDA

Posts: 1,380

|

|

Not Ranked

Not Ranked

mfarrell

Are jetting is almost identical.

Where are you located?

|

03-05-2009, 11:27 PM

|

|

CC Member

|

|

|

Join Date: Jun 2003

Location: Palma de Mallorca, Spain,

ESP

Cobra Make, Engine: Contemporary with 482 KC/SO, TKO600,IRS Jag/AMP, 3.54 Salisbury PL,

Posts: 578

|

|

Not Ranked

Not Ranked

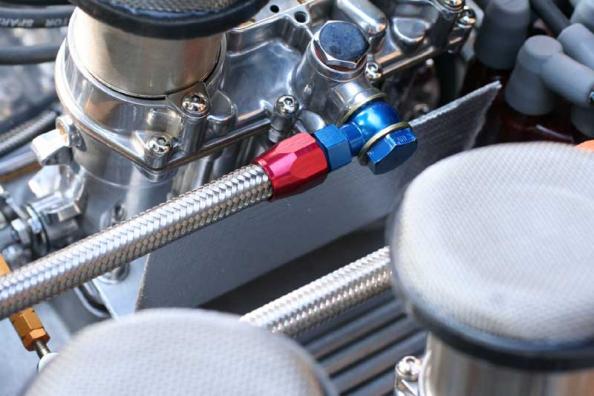

These are pictures of the phenolic spacer under the carbs, which definitely help in preventing them getting hot while driving. I have also made myself phenolic spacers for under the screwhead to prevent heat from beeing transmitted through there . The screws are stainless steel, which transmit heat mores slowly. This is a partial solution to the problem.

I also made myself a heatshiel, which is aluminum plate with heatshield material stuck on the outer surface. The heatshield does also wrap at the bottom below the fuel bowl. This heatshield has been of no help whatsoever.

My jetting is 40mm chokes, 145 mains,F14, 100 air corrector, 65 idle with 100 idel holder, 00 bypass for pump.

When I come back from a ride the carbs are cool to the touch. They get a lot of cooling from the air comming into the scoop.

Once the car stands still all the heat from the engine goes up the engine bay and slowly goes out through the scoop, but not fast enough, which makes the Webers pick up all that heat and get really hot depending on the outside temperature.

I tried the smallest bypass 0.35 for the pump circuit but still got the nasty dripping. I will put them back in because I made so many changes that I do not remember if I had the phenolic spacers on when I tried using the 0.35 bypass.

My plugs are light tan and the car runs great. Of course forget about 14.7 A/F ratio. If I get anywhere close to that I notice less power and the plugs get too light a color. So this engine need more fuel to run well.

The best thing is to read the plugs.

Run the car at around 4000 rpm for 10 minutes, then without letting bthe rps drop simultaneously turn off the ignition and press the clutch to release the gear to permit the engine to stop rotating. Now stop the car and take out the plugs. That color will tell you where you are.

__________________

Nothing sounds better than a Cobra in a Tunnel !

|

03-06-2009, 06:29 AM

|

|

CC Member

|

|

|

Join Date: Mar 2004

Location: miami,

FL

Cobra Make, Engine: E-M Cobra Ford FE 427 w/ Webers 48 IDA

Posts: 1,380

|

|

Not Ranked

Not Ranked

Eljaro,

Have you tried running different fuel to see if you still experience the dripping?

I moved away from the 00 bypass and that solved 90 % of my problem. This corrected my problem so much that I can not see the fuel drip on the plates.

However, what I am able to notice now is that the fuel will slowly / slightly drip from the progression hole. The fuel is so little that it will evaporate before it has time to stop and accumilate any volume.

I had to change my jetting around to compensate for the 55 bypass. Here are the specs.

40 choke

120 holder

65 idle jet

210 aircorrector

F2 emulsion

150 main

55 bypass

mixture screw at 7/8 turn.

Plugs tan in color

I am interested in running AV gas to see if the article is correct / my theory. There is is just too much junk in the fuel today to have good fuel.

I have noticed tha the mixture should be about 13.5 /13.8 minimum and at cruise with no demand from the motor I could go 14.5. But as soon as I hit the gass to demand power it will drop to 12.7 then level off back to 13.5.

This seems to work for me.

I will try with no change the 42 mm then move on to no choke.

By the way, what brand fuel fitting are you using? the banjo fittings are the individual run or did you find a banjo with a in then out to the next carb. What would be that part number.

Last edited by priobe; 03-06-2009 at 06:31 AM..

|

03-06-2009, 03:29 PM

|

|

CC Member

|

|

|

Join Date: Jun 2003

Location: Palma de Mallorca, Spain,

ESP

Cobra Make, Engine: Contemporary with 482 KC/SO, TKO600,IRS Jag/AMP, 3.54 Salisbury PL,

Posts: 578

|

|

Not Ranked

Not Ranked

Earls has a double sided banjo #807992 and a single sided #807692 one.

__________________

Nothing sounds better than a Cobra in a Tunnel !

|

03-15-2009, 03:27 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: May 2007

Location: San Clemente,

CA

Cobra Make, Engine: CSX 4758, CSX 381 Keith Craft 482 w/ Weber 48 IDA's

Posts: 492

|

|

Not Ranked

Not Ranked

Eureka!

I did a couple of things, after I got the new setup to idle and run without popping. Lowered the fuel level in the bowls like Rick and Phil suggested. I used Phil's method of measuring the tang dimensions (.220). Secondly, I installed the F11 Etubes and stayed with the 135 mains, 65 idles. Idle mixture screws exactly 1 and 1/2 turns. Virtually no idle speed screw. Idle at 750-800. Lastly, a bottle of Lucas Octane Booster in the tank (20 gal +/-).

Almost no dripping or percolating at shutdown. Before it would happen about 3 to 4 minutes after shutdown, and spill a lot out of the squirters and bubble for about 8-10 minutes. Now, just a tiny bit dribbles, but not enough to be concerned about, and it doesn't leak out of the gaskets onto the intake like it did earlier. Thanks Brent for the article about winter, fall, spring and summer gas mixes. I think this combo, synthesized from all you guys, did it. I'm thrilled!!

|

04-07-2009, 03:39 PM

|

|

CC Member

|

|

|

Join Date: Sep 2006

Location: Skjetten,

No

Cobra Make, Engine: Unfortunataly ; none

Posts: 333

|

|

Not Ranked

Not Ranked

As Eljaro suggests; I changed to a return- type fuel pressure regulator and doubled the amount of insulating material (2 x gaskets) between carbs and inlet manifold and together with a slightly richer idle mixture, the gasoline-boiling stopped...

Runes

|

04-17-2009, 01:56 PM

|

|

CC Member

|

|

|

Join Date: Mar 2000

Location: Des Moines,

IA

Cobra Make, Engine: Sold my beloved Shelby CSX 4068, Gessford 427 Ford

Posts: 756

|

|

Not Ranked

Not Ranked

What fuel pressure?

What fuel pressure?

What fuel pressure are you guys running on your Webers? If you are using a typical 6-7 psi as on a Holley, you have yet another problem to cure. Webers need 3-4 psi, no more. 4 pages and no one has asked?

__________________

CSX4068, '69 Bronco, '70 BOSS 302, '87 Mustang GT, '08 Roush Trak Pak

|

04-17-2009, 02:00 PM

|

|

CC Member

|

|

|

Join Date: Mar 2004

Location: miami,

FL

Cobra Make, Engine: E-M Cobra Ford FE 427 w/ Webers 48 IDA

Posts: 1,380

|

|

Not Ranked

Not Ranked

Doug,

This thread is not about the pressure. It is more related to the perculation of the fuel.

Most of use on the thread are aware of the fuel pressure of the Webers.

The fuel leak happens after the motor has been turned off

|

04-17-2009, 02:13 PM

|

|

CC Member

|

|

|

Join Date: Mar 2000

Location: Des Moines,

IA

Cobra Make, Engine: Sold my beloved Shelby CSX 4068, Gessford 427 Ford

Posts: 756

|

|

Not Ranked

Not Ranked

OK. I understand.

There are references to idle problems, float levels, etc., that appear to be rather elementary for someone who is experienced in Weber tuning. I suspect several are not as knowlegeable as all that. Nor am I, for that matter, and since I don't have a dog in this hunt, I'll fade quietly away.........

__________________

CSX4068, '69 Bronco, '70 BOSS 302, '87 Mustang GT, '08 Roush Trak Pak

|

04-17-2009, 06:46 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: May 2007

Location: San Clemente,

CA

Cobra Make, Engine: CSX 4758, CSX 381 Keith Craft 482 w/ Weber 48 IDA's

Posts: 492

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by DougD

What fuel pressure are you guys running on your Webers? If you are using a typical 6-7 psi as on a Holley, you have yet another problem to cure. Webers need 3-4 psi, no more. 4 pages and no one has asked?

|

Doug, like Phil said, 3-3.5 psi at the inlet is Webers 101 for just about all of us who embarked on Webers. I use a Holley pressure regulator with a return line to the tank. My dripping is almost non-existent now. But the beast still runs rich. I'll have to keep tinkering. But it runs like an M-F'er. |

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 05:31 PM.

Links monetized by VigLink

|