Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

1 |

2 |

| 3 |

4 |

5 |

6 |

7 |

8 |

9 |

| 10 |

11 |

12 |

13 |

14 |

15 |

16 |

| 17 |

18 |

19 |

20 |

21 |

22 |

23 |

| 24 |

25 |

26 |

27 |

28 |

29 |

30 |

|

CC Advertisers

CC Advertisers

|

|

08-13-2009, 03:59 PM

|

|

CC Member

|

|

|

Join Date: Mar 2004

Location: miami,

FL

Cobra Make, Engine: E-M Cobra Ford FE 427 w/ Webers 48 IDA

Posts: 1,380

|

|

Not Ranked

Not Ranked

Wouldn't it be dependent on alot of factors rather than CI.

As example, camshaft spec, compression ratio, ported heads, valve size etc

I am just learning here, I dont mean to start a debate  |

08-13-2009, 04:08 PM

|

|

CC Member

|

|

|

Join Date: Aug 2007

Cobra Make, Engine: 31XX Car

Posts: 374

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by priobe

Wouldn't it be dependent on alot of factors rather than CI.

As example, camshaft spec, compression ratio, ported heads, valve size etc:

|

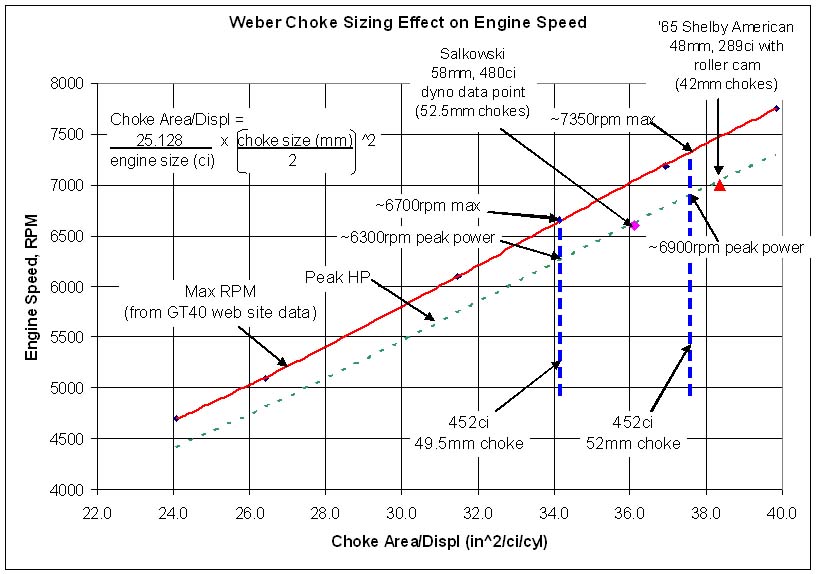

Those factors would effect volumetric efficiency and airflow demand, so yes they have an impact, but probably more second order. It kind of already ties into the rpm demand, ie you couldn't have an engine that makes peak power at 7,000 rpm if it doesn't have good heads, cam, etc. The chart is intended as a ballpark. Some people are happy with engine configurations somewhat above or below this curve. I think it should be looked at as an indicator where if you have an engine which is stoutly built and you run chokes that plot to the left of the dashed curve, then you may have great off idle response, but you're most likely limiting your performance potential to a significant degree (and many in this category bad mouth webers for loosing steam at top end). Conversely, if you're running chokes that plot to the right of this curve, then you may be getting a few more HP at top end, but will generally have disproportionately poor low speed performance, including a much greater tendency for the legendary part throttle transition stumble (may not be important on a race car).

|

08-14-2009, 03:20 AM

|

|

CC Member

|

|

|

Join Date: Sep 2006

Location: Skjetten,

No

Cobra Make, Engine: Unfortunataly ; none

Posts: 333

|

|

Not Ranked

Not Ranked

E- tubes

E- tubes

Agree some with those saying "the more I read, the more confused.....".

One of my Weber books , by PatBraden, have tables of e-tubes and tuning preference.

In one table F7 is said to be lean, in another "richer low end"...

Well; I run F11 in my IDF's on the 347. If I read GAZ64's table correct, this would be rather unusable (cylinder size 250- 325 ccm). But, my engine is running well, ableit a little rich (A/F 10,5- 12,5) on RPM range from 3000- 7500.

In all tables I have senn F11 is placed in the "normal use" group.

F2 I find under "Alcohol usage".... So, very rich, then?

If someone steps up and says "You should use F..", I'd go and buy a set . If then engine runs smoother and with more correct A/F than ever, I would really appreciate & look up to this person, indeed.

Anyone wants to make some definte conclusions on E-tubes?????

|

08-14-2009, 08:09 AM

|

|

CC Member

|

|

|

Join Date: Mar 2004

Location: miami,

FL

Cobra Make, Engine: E-M Cobra Ford FE 427 w/ Webers 48 IDA

Posts: 1,380

|

|

Not Ranked

Not Ranked

Caprimaniac,

If you are running good on your idle to 3000 I would not change the emulsion tube.

What I would change depending on where you are experiencing the 12.5 A/F.

If it is higher RPM like 4000 then I would lower the air corrector.

What is mains and aircorrector jets?

At what RPM is you A/F mixture experiencing 12.5

|

08-14-2009, 11:54 AM

|

|

CC Member

|

|

|

Join Date: Mar 2004

Location: miami,

FL

Cobra Make, Engine: E-M Cobra Ford FE 427 w/ Webers 48 IDA

Posts: 1,380

|

|

Not Ranked

Not Ranked

DCMgt,

I dont understand your graph with the formula ( I must be doing something wrong)

By your chart what choke is recommended for a Ford FE 427 motor for HP and Torque.

|

08-14-2009, 11:59 AM

|

|

CC Member

|

|

|

Join Date: Sep 2006

Location: Skjetten,

No

Cobra Make, Engine: Unfortunataly ; none

Posts: 333

|

|

Not Ranked

Not Ranked

A/F etc

A/F etc

Hi, Priobe/ all.

The 11-12 AF was above 4000.

In the 10's from 2000 when flooring the pedal.

Engine is running fine (but a litle rich) up to 3000.

40 chokes, 165 mains 200 (190) air corr.

Tried 140 mains today: A/F 16 at 5000 rpm.

Changing back to 165 mains, getting larger air corr. later on.

220?

Think moving up more will make A/F too low, since changing 165- 140 made such a difference.

Have to go'n change the mains. Track- day on sunday, mother in law's 50'th anniversary tomorrow....

|

08-14-2009, 12:02 PM

|

|

CC Member

|

|

|

Join Date: Mar 2004

Location: miami,

FL

Cobra Make, Engine: E-M Cobra Ford FE 427 w/ Webers 48 IDA

Posts: 1,380

|

|

Not Ranked

Not Ranked

145 to 165 is a huge change.

I would change to 160

|

08-14-2009, 12:21 PM

|

|

CC Member

|

|

|

Join Date: Aug 2007

Cobra Make, Engine: 31XX Car

Posts: 374

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by priobe

DCMgt,

I dont understand your graph with the formula ( I must be doing something wrong)

By your chart what choke is recommended for a Ford FE 427 motor for HP and Torque.

|

Do you have a dyno plot showing what rpm your engine makes peak power? If not, what is your guesstimate of that rpm or where would you like it to occur? Please also confirm whether you have 427 ci and not running a stroker crank. |

08-14-2009, 12:21 PM

|

|

CC Member

|

|

|

Join Date: Mar 2004

Location: miami,

FL

Cobra Make, Engine: E-M Cobra Ford FE 427 w/ Webers 48 IDA

Posts: 1,380

|

|

Not Ranked

Not Ranked

Scratch my last post

I would change the exhaust valve.

What value is it?

|

08-14-2009, 12:24 PM

|

|

CC Member

|

|

|

Join Date: Mar 2004

Location: miami,

FL

Cobra Make, Engine: E-M Cobra Ford FE 427 w/ Webers 48 IDA

Posts: 1,380

|

|

Not Ranked

Not Ranked

Dcmgt,

Peak power was made 5800 rpm ( If memory is correct).

It is a 427 Ci

|

08-14-2009, 01:14 PM

|

|

CC Member

|

|

|

Join Date: Aug 2007

Cobra Make, Engine: 31XX Car

Posts: 374

|

|

Not Ranked

Not Ranked

Choke size

Choke size

Quote:

Originally Posted by priobe

Dcmgt,

Peak power was made 5800 rpm ( If memory is correct).

It is a 427 Ci

|

Ok, for peak power at 5800, the choke/displ parameter would be about 32. Rearranging the equation and plugging in yields 2*(32*427/25.128)^1/2 = 46.6mm choke diameter if you don't want power to be limited by choke size.

There is a rule of thumb of how much greater the carb bore size should be than the choke and I recall it's around 20% by memory (can't remember whether that was based on diameter or area). So a 46.6mm choke ratio'd up by 1.2 is about 55.9mm carb bore. Now imagine if you wanted peak power more in the 6500+rpm range, you can see how the ideal choke size would approach 50mm and the bore size to go along with that is 58mm........we just went through a similar exercise to what Shelby American/Ken Miles went through to determine carb size when they were developing the big block Cobra race cars.

For you're planned usage, it would probably be ideal to have 48mm IDA carbs bored out to 52mm (a common procedure done by shops I believe like Berg) and run something like 45mm chokes.

Last edited by DMXF; 08-14-2009 at 01:17 PM..

|

08-14-2009, 02:01 PM

|

|

CC Member

|

|

|

Join Date: Mar 2004

Location: miami,

FL

Cobra Make, Engine: E-M Cobra Ford FE 427 w/ Webers 48 IDA

Posts: 1,380

|

|

Not Ranked

Not Ranked

Dcmgt,

I see what you are saying and understand,however I dont see this yeilding a significate advantage for the cost of boring the carbs.

Also this sinario would be for max HP not torque. Is this correct?

If so, then in reducing the choke size from 45 to say 42 - 43 may be better for better throttle response coming out of a corner or stop and go driving.

Another thing that I am not clear about is if the camshaft is designed to carry you to a particular RPM range you can actually decrease power by increasing the size of the choke trying to carry the motro to a highr RPM range.

Is this correct?

|

08-14-2009, 02:28 PM

|

|

CC Member

|

|

|

Join Date: Aug 2007

Cobra Make, Engine: 31XX Car

Posts: 374

|

|

Not Ranked

Not Ranked

chokes

chokes

That cost-benefit issue rears it's head quite often. I think you can find 45mm chokes to drop right in your 48IDA's. I've heard of guys running stright tubes for chokes at the 48mm bore size, although anything approaching that is not be design and may have side effects.

From numerous dyno plots I've seen comparing carbs (in general) of different sizes, going larger in choke/bore size to a point increases power at all rpm's from at least 3000 on up (so mid range torque and HP increase). Dyno results don't tell you, however, about driveability off idle up through 2000rpm, which suffers as you go larger. So, yes, in most cases smaller carbs will "feel" better in traffic use. If you're up to the challenge, getting the larger carbs to run smoothly at lower engine speeds will give you a stout ride. You would probably have to go real big, beyond practical, to start decreasing power across a wide spectrum of engine speed. But you can try different things for yourself and let us know how well all this fits with your configuration.

|

08-14-2009, 02:45 PM

|

|

CC Member

|

|

|

Join Date: Mar 2004

Location: miami,

FL

Cobra Make, Engine: E-M Cobra Ford FE 427 w/ Webers 48 IDA

Posts: 1,380

|

|

Not Ranked

Not Ranked

Thanks for the post.

I think I will try the 42 which I have on hand then might purchased 45 / 46 mm for giggles.

Finally if that work out for me then I will try no chokes.

I have been playing with these carb for a few years and aquired a very wide range of jets and Etubes so another $100 or so, for extra chokes cant hurt the pockets anymore

|

08-14-2009, 04:26 PM

|

|

CC Member

|

|

|

Join Date: Aug 2007

Cobra Make, Engine: 31XX Car

Posts: 374

|

|

Not Ranked

Not Ranked

Choke Benefits

Choke Benefits

Keep in mind choke size effect probably has limited benefit analogous to other parameters, like cam specs. For example, if you have a bone stock 390 and try putting bigger cams in, the performance increase will likely be marginal. In contrast, if you do the same thing with a Keith Craft built 500+ ci 650hp FE monster, the power difference between a stock 390 cam and a high lift & duration roller will be tremendous. It's more an issue of allowing the engine to make the power and rpm it was designed for rather than it forcing the engine to turn more rpm than it should.

|

08-14-2009, 04:31 PM

|

|

CC Member

|

|

|

Join Date: May 2008

Location: Brisbane,

QLD

Cobra Make, Engine:

Posts: 2,797

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Dcmgt

Probably just wasting my time posting it, but here goes:

You can back calculate the choke size by picking an appropriate point on the line and then rearrange the equation (plugging in your displacement). |

Hi, like others I can't understand the formula involved.

Can you elaborate on "^2"?

I can't seem to get any reasonable answer for my cars.

__________________

Gary

Gold Certified Holden Technician

|

08-14-2009, 06:43 PM

|

|

CC Member

|

|

|

Join Date: Aug 2007

Cobra Make, Engine: 31XX Car

Posts: 374

|

|

Not Ranked

Not Ranked

Chart

Chart

Gary - That means square the resulting value within the brackets.

We still need someone to model the emulsion tubes...........

|

08-15-2009, 03:21 AM

|

|

CC Member

|

|

|

Join Date: Sep 2006

Location: Skjetten,

No

Cobra Make, Engine: Unfortunataly ; none

Posts: 333

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by priobe

Scratch my last post

I would change the exhaust valve.

What value is it?

|

Priobe, your question goes to me, right?

Exhaust are blank. 000.

I've been thinking about this; would it work better with an exhaust valve?

I think no; the extra fuel is needed when flooring. Above around 4- 5000 they probably don't make any difference.

Books say and other members say: size 00 exhaust for performance use...

(These ar IDF's, not IDA's....) |

08-15-2009, 05:32 AM

|

|

CC Member

|

|

|

Join Date: Mar 2004

Location: miami,

FL

Cobra Make, Engine: E-M Cobra Ford FE 427 w/ Webers 48 IDA

Posts: 1,380

|

|

Neutral

Neutral

caprimaniac,

1 thing I noticed is that by changing the exhaust while driving normal makes a difference. I know many might say this circuit is only for when the pedal is being pressed. Well, I agree with that , however you will be surprised how much you foot will move on the accellerator when you think you are holding the throttle at a certain rate. Dont take my word for it, do this. Go get your self a throttle position sensor. Mount it to the carb body, and use a volt meter to test how still you foot is on the throttle. I am willing to bet that you foot moves creating extra fuel when you think it is completely still.

Then, you can see if you really need different exhaust valves.

If you have a LM1 A/R meter then you are half way there. If not, it will be very difficult to fine your carbs.

With the IDF, they make a mounting bracket for your setup already. So this should be 1,2,3.

If you need help with the wiring let me know.

|

08-19-2009, 03:43 PM

|

|

CC Member

|

|

|

Join Date: Sep 2006

Location: Skjetten,

No

Cobra Make, Engine: Unfortunataly ; none

Posts: 333

|

|

Not Ranked

Not Ranked

Ok, Priobe- this have been into my mind as well; so: I will change air jets first and then see. If A/F is OK at wide open, and still around 10- 11 lower in the RPM scale,the exhaust has to be changed. Definitive.

I visited a racetrack last weekend and did alot of testing: In 4., the engine completely stalls at 4000 rpm, no matter what- if you gon on and off then on again; still the same. If you flloor the pedal; no answer either.

But; If revved to 7- 7500 rpm in 3., it hits 5000 or so in 4. and then it goes on (although not too far, the longest straight lets you go like 190 KMH (110- MPH), so I guess maximum 6200 in 4.?).

To be honest, the engine runs like crap, (is it weather- sick? it rained...) and I'm onto trying different things:

- Going to colder plugs

- Reducing the cold air scoop

- Removing closed "pressure box" around the carb air horns

- Using "boxed" K&N filters

(- Larger air jets and mesh filters for the air horns will go in next week)

Thanks for all the feedback

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 09:08 AM.

Links monetized by VigLink

|