I always admired those of you who documented your builds and shared with those of us too chicken to head down that path. In other words, us guys who just went out and bought one. But then I began to realize how long it was going to take me to actually get mine on the road in a condition that I was comfortable with. So took a couple pics and made a couple of notes and here it is. Rather than a step by step posting over 10 months, here it is all in one big lump.

This is pretty long winded, written mostly to assist my already pathetic memory. So if ya donít enjoy a good novel once in a while, yíoughta just skip to the next post.

Finally picked up a B&B cobra replica last October and figured it to be on the road early spring.

It was being driven and after all, seller said it was in good condition, needed nothing, and it looked it. Needed some work to the radiator fan he said, (overheated immediately when it was turned on manually, figgered it was wired backwards) and the parking brake needed adjusting. Hey, anybody can adjust a parking brake, huh? Ah, but! The closer I looked, the more problems I found. And the more problems I found, the closer I looked. Still wondering if I have looked closely enough!!!! The following isnít all of it, just what I remembered to write down at the time.

1. Steering seemed a tad bit loose and I thought it was in the rack. Probably a donor rack and anyway I wanted to quicken up the steering, so I picked up a new rack from FR. When I got the old one off, I found out that it was broken. Yup, crack the length of it an eighth of an inch wide.

Some owner (probably all of Ďem) before me was sure lucky. (Can you imagine driving a high performance car spiritedly with a broken steering rack?) Tried to bolt the new one in. Uh uh, not gonna go. What the???? Now my car has this nice (I think) Heidtís complete front end under it with the tubular a arms and all that other good stuff, and a rack that hits the lower A-arms. Hits the lower A-arms? Looks like sumbody missed sumpin sumwheres. Machined up a couple of adapters to re-position the rack, shortened the steering shaft, and weíre good to go on that one after an alignment. I donít think that I repositioned the rack enough to alter the steering geometry and anyway, I was not going to re-assemble it the way it was and break another rack. In the process, I pulled the steering column to repaint the fisheyes on it. That was a major job in itself as it as assembled in a manner in which the entire dashboard would have needed to be pulled to get the column out. Made a few necessary modifications there!! Actually got it out without touching the dash mountings. WHY do they do that?

2. In the process of above, noticed a couple of loose bolts and nuts, so figured I would check them all. GOOD idear. Lots and lots of loose fasteners all over the car including some suspension ones that I kinda suspect just might be a little crucial and the bolts on the left rear caliper? The car did actually come in with all parts attached. Somehow. I suppose all in all I tightened 50 to 60 nuts and bolts, lots of them only finger tight.

3. So I tackle the parking brake. Lever mechanism is all but scrap (15k on car) not good quality, but hey, I own a machine shop, I can fixit. Bushed the pawl, new spring, welded and re-cut the oversize rectangular hole in the link to the cables, Then realized that the round post coming off the side at the bottom had been welded on wrong. Took care of that in the cable link piece. Assemble and Iím done, right ? Notachance. Now that the above are all corrected, I discover that the parking brake on the Lincoln Versailles rear end just does not work. Thank God for Google, praise to Google. Finally figgered out how to adjust those nasty things (Now I know why Ford only made them for a couple of years.) Hours and hours later I finally had those bad boys adjusted up correctly. But wait a minute, the location where the mounts for the cables are welded to the frame donít allow ANY mechanical advantage to be applied to the brake cams. I am just Not gonna cut and re-weld on the frame. Made some new mounting sockets for the cable ends and welded them to the cams.

Lotsa mechanical advantage and pulling in the right direction now, just hook up the cables and done, right? Hah, you already know the answer, the cables are too short. The only way they were on the car originally was that the brakes were so far out of adjustment they actually fit. Made an adapter for the end of the brake lever to extend it toward the back of the car and finally the hand brake is done. and functional

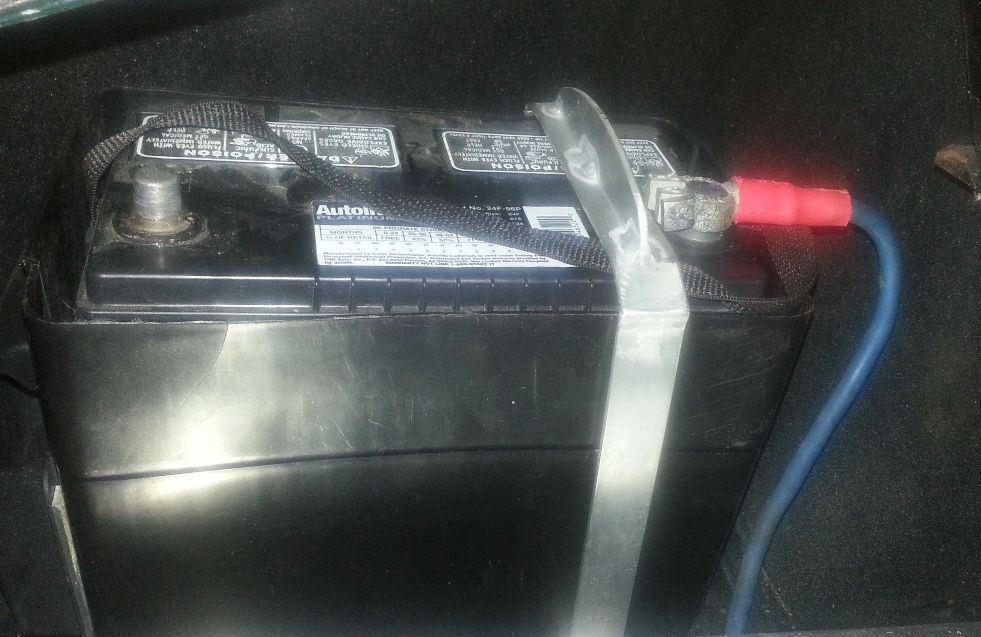

4. Bought a really nice car cover that I keep my baby covered up with, and take it off when I am searching for new problems, or just sitting in it drooling. So one evening I takes myself to the garage, removes the cover, tosses it in the trunk, and WHAT THE? Major spitzensparken!!! Jerk the cover out and pull the battery hold down off of the positive terminal where it was attempting to weld itself permanently while also setting anything nearby on fire. I patted the fuel cell and smiled.

Back from the bathroom I removed the hold down and wondered at the extremely lucky previous owners. I mean, acceleration does cause the loose battery to move toward the rear where the hold down was anxiously awaiting the chance to ruin somebodyís day. Battery was toast, but it was 7 years old anyway. Nice black nylon blocks fitted to the hold down should permanently solve this one.

5. The wiper ferrules were only hand tight

6. There was an unconnected vacuum line laying on the intake manifold

7. The vacuum line from the carb plate to the distributor was too large for the fittings and leaking at each end

8. Both seats needed to be re-mounted. When I was done I had a pound of extra hardware and a quarter sheet of plywood left over. The passenger seat alone took me almost 2 hours to remove, and Iím pretty good with tools. At least when it comes to taking stuff apart.

Some previous owner had installed the seats with inch and a half long slotted wood screws put in from under the seat. Keep in mind that there is only about 2 inches space under the seat to the floor. HOW DID HE DO IT?

9. Finding all the above problems, I figured Iíd better check the positive cable the length of the car. Beautiful perfect work. But, but, the ground cable was a piece of work of another sort. No tywraps anywhere and all connections made over painted surfaces. Nope, nope, nope, not metallic paint. Scraped, scotchbrited, joint compound, and voila, no more electrical problems. At all. Oh by the way, did I mention that when the car was delivered, the only two things electrical that worked were the starter and the ignition?

10. Map light wired permanently on, no switch anywhere.

11. The right rear caliper was assembled incorrectly

12. The right rear shock was assembled incorrectly with the coilover not seated on the top pivot and hitting the shock hard at the top. Wore about 1/8 inch off the outside diameter of the shock housing on one side. That hadda make a totally hideous noise. Nobody EVER noticed? Stuff on the left side was great.

13. Tire pressure was at 35-40. Previous owner told me to make sure to run about 35. Rear tire tread in center is a bit sketchy. Wonder what coulda caused that????

14. There was barely enough clearance between the turn signal stalk and the steering wheel to get your hand in.

15. Passenger door didnít close completely and rattled badly

16. Pedals totally misaligned, brake about 3 inches above clutch and the loud pedal hit you low on the arch. Adjusted the positions of the brake and clutch and totally rebuilt the accelerator pedal, see below.

17. There was a very nice black leather upholstered panel fit in the driverís foot well right next to the clutch pedal. Moved that sucker 4 inches to port!

18. Completely reworked the balance bar to adjust it, take out play, keep it from hitting the frame, and probably other stuff I just canít remember. Oh yeah, doesnít rattle any more either.

19. Cut, welded, made new pieces, and probably totally over-engineered the badly designed and mis-installed accelerator pedal.

I am sure that I could have bought a perfectly suitable one for far less than the value of the time I have in the one that came on the car. But sometimes ya just gotta.

20. Re-glued the carpet behind the seats and most of the weather stripping

21. Adjusted the trunk lid hinges

22. Replaced the missing hood bumpers

23. Adjusted the hood latches

24. Replaced the missing breather tube

25. Make a new carb gasket to replace the missing one

26. Made a cover for the fuel cell sending unit

27. Removed that nasty neutral switch

28. Added lots of wire tyís and cable guarding. Re-routed lotsa wiring and ended up with yards and yards of spare wire left over.

29. Re-glued the tabs for the door panels

30. Added a gas pedal stop so as not to stress the carb linkage

31. Replace the loose and rattling

oil filler cap that probably would have come off the first hard bump anyway

32. Havenít figured out yet how to stop the clutch and brake pedals from rattling. I know, I know, just take Ďem apart and put new bushings and washers in right? Wrong. The bolts were put in from the wrong direction (nuts shoulda been there) and now they wonít come out without dropping all three master cylinders and the whole pedal assy. This WILL be a unique solution, when I figure it out, I am sure.

33. Both door latches were loose

34. The throttle cable was rubbing on the steering shaft, re-positioned and tied it down

35. Accelerator pedal had been mounted in the wrong position and wore a slot all the way thru the fitting thru the firewall. Replaced it and re-mounted the pedal

36. The ignition coil mount was loose and the coil was just rattling around, hanging from the wiring

37. Wiring in part was less than stellar. Other parts of it couldnít be improved upon. I used lotsa wire loom covering and wire tyís. Re-ran a bunch of the wiring to neaten it up and get it away from sharp metal edges. (Donít know why this car didnít burn to the ground in a past life.) Ended up with many many yards of removed wire on the floor and everything still works, or works now. Feel good enough about it to take it out of town. Or at least around the block..

38. Wiper blades set way below the windshield and totally loose. Both needed to be re-bent to line up with the windshield frame.

39. Gear shift lever waaay too long,

took about 6 inches off that puppy and got rid of the phallic gearshift knob

Oh Yeah, changed the steering wheel too

40. Reworked the cobbled windshield rod/mount/brace. I have no idea how some previous owner got it put together. Took me an hour and a half to get it apart what with the mismatched fasteners, cross threaded nuts on the brace rod, and stripped out screw heads. Made new pieces, re-threaded the rod, and traded in all fasteners for socket heads.

41. Added side pipe guards. Driverís side went smooth as could be.

Passenger side wouldnít go on. There was a full inch less room between the sidepipe and the body on the right side than the left side. Made up a 1 inch thick aluminum spacer, sidepipe mount extension, and a couple of new gaskets and now both sides are identical. Yeah, well, mirror images.

So my question: Is this normal when buying one of these cars, or did I just get one that looked fine but had lots of demons lurking under the skin? Are most used cobras sorted or full or surprises like Iíve encountered? Lots of these items I didnít see at all when I gave the car the first look over, some not until I disassembled (like the rack). Both sad and scary that guys without the necessary skills are putting vehicles together and driving them on the road when they shouldnít even be trying to change the wheels on their roller skates.

In spite of all the above I am pretty satisfied with the car mechanically, extremely pleased with the way it looks, and think that it came at a good price. (have already turned down an offer considerably more than I paid for it) There is a lot of work that is impeccably done (first owner?) and there is some that is as bad as can be imagined (second owner?). The immediately previous owner (looks like there have been lots of Ďem) was obviously not a car guy. Sadly I have not been able to trace the history of the car back past just a couple of years. NO idea what is inside that engine.

Yet to be done, change the windshield angle, eliminate the roll bar if the bodywork is not too expensive, fit the tonneau, side curtains, and top, add fog lites, and change to black exhaust.

Okay, thatís enough from me and thanx to both of you guys who actually made it all the way to the end of this. (those of you who skipped to here need not be ashamed) This is a great forum, I have enjoyed it immensely and learned an incredible amount in the process. Sorry that I have not been posting much, canít seem to get out of the garageÖÖ