Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

|

1 |

| 2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 9 |

10 |

11 |

12 |

13 |

14 |

15 |

| 16 |

17 |

18 |

19 |

20 |

21 |

22 |

| 23 |

24 |

25 |

26 |

27 |

28 |

|

|

CC Advertisers

CC Advertisers

|

|

6Likes 6Likes

-

1

Post By Bill D

1

Post By Bill D

-

2

Post By mickmate

2

Post By mickmate

-

1

Post By Three Peaks

1

Post By Three Peaks

-

1

Post By redmt

1

Post By redmt

-

1

Post By Bill D

1

Post By Bill D

12-08-2014, 02:58 PM

|

|

CC Member

|

|

|

Join Date: Jul 2006

Location: Redding,

CA

Cobra Make, Engine: FFR chassis and suspension, Mr. Bruce 289 FIA body

Posts: 1,066

|

|

Not Ranked

Not Ranked

Need some guidance before I proceed

Need some guidance before I proceed

Ok, the time has come to weld together my 289 forward braced roll bar. But before I proceed with what I believe is the correct approach, I would like the pros to chime in.

I plan to cut the forward brace about 8" from the point where it welds to the hoop. Will then weld the insert into the top pice with a series of rosette welds. I will then put the two pieces together and drill the holes in the bottom piece to secure the two pieces.

Next I will install the hoop and align the brace, tack weld, remove, and final weld.

Let me know if this is the correct way or not. I plan to use 5/16 grade 8 bolts (2) to secure the upper and lower portions of the forward brace

Thanks

Bill D

Last edited by Bill D; 12-08-2014 at 03:02 PM..

|

12-09-2014, 03:52 AM

|

|

CC Member

|

|

|

Join Date: Dec 2004

Location: Kansas City,

KS

Cobra Make, Engine: jbl

Posts: 2,291

|

|

Not Ranked

Not Ranked

Not familiar with your setup but the final weld could possibly move things around a little depending how hot the parts get, shrinkage you know, allow for movement.

|

12-09-2014, 04:39 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Sep 2000

Location: Holderness, NH, US of A,

NH

Cobra Make, Engine: CSX 4772 old iron FE

Posts: 5,499

|

|

Not Ranked

Not Ranked

Sounds good Bill. Take a little time on the fit of the fish mouth. As vector points out the weld shrinkage is a consideration and a good fit minimizes that. Balance the welds if you can. Weld one side and spin and weld the other. Sides first because the ends really change the angle, especially the underneath one. I use 3/8" bolts on the 7's but 5/16" grade 8 should be fine, they are in double shear.

|

12-13-2014, 11:00 PM

|

|

Registered User

|

|

|

Join Date: Dec 2014

Cobra Make, Engine:

Posts: 36

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by mickmate

Sounds good Bill. Take a little time on the fit of the fish mouth. As vector points out the weld shrinkage is a consideration and a good fit minimizes that. Balance the welds if you can. Weld one side and spin and weld the other. Sides first because the ends really change the angle, especially the underneath one. I use 3/8" bolts on the 7's but 5/16" grade 8 should be fine, they are in double shear.

|

Not sure I would follow this guy's advice, looking at that frame he built that was cut up sure looked questionable in the welding. |

12-14-2014, 10:19 AM

|

|

CC Member

|

|

|

Join Date: Jan 2005

Location: Hillsboro,

OR

Cobra Make, Engine: Scratch built CSX style frame, Carbon fiber body, 393 Stroker, T-bird IRS, T5

Posts: 1,623

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Scott427

Not sure I would follow this guy's advice, looking at that frame he built that was cut up sure looked questionable in the welding.

|

Scott427, how about describing your expertise as a welder so we can determine if your criticism of someone else's work is warranted or just more BS piling on Nick here. A couple pics don't really tell the whole story IMHO. |

12-14-2014, 07:08 PM

|

|

Senior CC Premier Member

|

|

|

Join Date: Nov 2004

Location: SoCal,

CA

Cobra Make, Engine: CSX #4xxx with CSX 482; David Kee Toploader

Posts: 3,574

|

|

Not Ranked

Not Ranked

I posted this on another thread, but will do so here as well.

These are most excellent on fitting pipe, IMHO.

Products | PipeMasterô - The Welder's Tool for Contour Fits

__________________

All that's stopping you now Son, is blind-raging fear.......

|

12-15-2014, 06:22 AM

|

|

CC Member

|

|

|

Join Date: Aug 2010

Location: San Antonio Valley Ca,

ca

Cobra Make, Engine:

Posts: 1,275

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Three Peaks

Scott427, how about describing your expertise as a welder so we can determine if your criticism of someone else's work is warranted or just more BS piling on Nick here. A couple pics don't really tell the whole story IMHO.

|

Would you like to see the pix of the Crapton welds that are on the crap he sent me? Your backing the wrong horse.

Would you like to see my welding credentials? I was certified structural, and high pressure vessel. I have over 40 years fabrication experience with stick, MIG, and gas welding. I was certified in carbon arc, and burning.

Crapton's welds are erratic and cold. His welds look like bird****.

Now, where's your credentials? |

12-15-2014, 01:51 PM

|

|

CC Member

|

|

|

Join Date: Dec 2010

Location: Allen,

TX

Cobra Make, Engine: Werk77 289FIA

Posts: 1,295

|

|

Not Ranked

Not Ranked

__________________

Scratch build 289 FIA see the Scratch builder forum on CC - sold

DRB GT40 MK1 red #49- sold

FF5 Mk4 #7733 302/T5/IRS - dark blue - sold

FF5 MK4 #7812 427/TKO/IRS - Guardsman Blue - sold

FF5 MK4 #8414 501/TKO600/48IDA Ollie the Dragon #91 - sold

FF5 Daytona Coupe 347/TKO/IRS Homage CSX2299 Viking Blue - sold

SPF 2063

|

12-15-2014, 07:16 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Mar 2005

Location: Manchester,

NH

Cobra Make, Engine: AK1085 (302 Street), HTM111 (427 Comp), CSX2375R (289 Comp) and COB5999 (427 S/C)

Posts: 19,072

|

|

Not Ranked

Not Ranked

Might want to fit a seat as the front brace looks short.

Looks great, just be sure the seat will not be blocked.

Mine extends into the footbox.

My frame is not as heavily modified just easier to check now than later.

Awesome job!

Last edited by 1985 CCX; 12-15-2014 at 07:21 PM..

|

12-15-2014, 07:18 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Mar 2005

Location: Manchester,

NH

Cobra Make, Engine: AK1085 (302 Street), HTM111 (427 Comp), CSX2375R (289 Comp) and COB5999 (427 S/C)

Posts: 19,072

|

|

Not Ranked

Not Ranked

Seat fit.

|

12-15-2014, 08:47 PM

|

|

Super Moderator

|

|

|

Join Date: May 2001

Location: Fresno,

CA

Cobra Make, Engine: KMP 184/482ci Shelby

Posts: 14,448

|

|

Not Ranked

Not Ranked

Gents...cool it.

Thank you for your expected cooperation.

__________________

Jamo

Last edited by Jamo; 12-15-2014 at 11:06 PM..

|

12-16-2014, 12:50 AM

|

|

CC Member

|

|

|

Join Date: Jul 2006

Location: Redding,

CA

Cobra Make, Engine: FFR chassis and suspension, Mr. Bruce 289 FIA body

Posts: 1,066

|

|

Not Ranked

Not Ranked

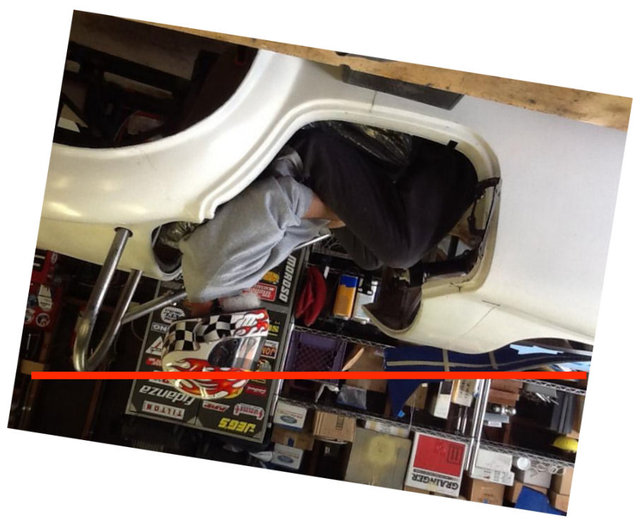

OK, got everything cut, fitted, and ready to be TIG

Drilled the mounting holes in one end of the insert

Welded the insert into the short section of the brace with 6 rosette welds

And filed the welds smooth, checking for voids, and rewelding as needed

Installed the hoop and brace, fitted the fishmouth and the point where the brace attaches to the frame

Installed the passenger seat and checked clearance

Last edited by Bill D; 12-16-2014 at 12:52 AM..

|

12-16-2014, 06:33 AM

|

|

CC Member

|

|

|

Join Date: Dec 2010

Location: Allen,

TX

Cobra Make, Engine: Werk77 289FIA

Posts: 1,295

|

|

Not Ranked

Not Ranked

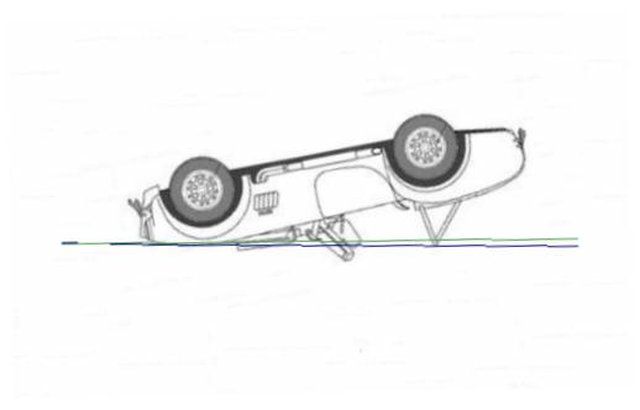

Do not bank so much on that rollbar. Back then, these rollbars were required to be able to get the driver out of the car when it was upside down.

Depending on how good you are strapped down in the car that rollbar (lack of rollcage) does not much to protect your melon.

Sorry to bust your bubble....

__________________

Scratch build 289 FIA see the Scratch builder forum on CC - sold

DRB GT40 MK1 red #49- sold

FF5 Mk4 #7733 302/T5/IRS - dark blue - sold

FF5 MK4 #7812 427/TKO/IRS - Guardsman Blue - sold

FF5 MK4 #8414 501/TKO600/48IDA Ollie the Dragon #91 - sold

FF5 Daytona Coupe 347/TKO/IRS Homage CSX2299 Viking Blue - sold

SPF 2063

|

12-16-2014, 04:12 PM

|

|

Registered User

|

|

|

Join Date: Dec 2014

Cobra Make, Engine:

Posts: 36

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Three Peaks

Scott427, how about describing your expertise as a welder so we can determine if your criticism of someone else's work is warranted or just more BS piling on Nick here. A couple pics don't really tell the whole story IMHO.

|

Call it want you want Sir, but it takes no experienced welder to look at those welds to see they are rough, and that's putting it nice.

As for pilling on the BS you bet, this work is very sub par.

What's your expertise to call it different? |

12-16-2014, 04:32 PM

|

|

Registered User

|

|

|

Join Date: Dec 2014

Cobra Make, Engine:

Posts: 36

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by redmt

Would you like to see the pix of the Crapton welds that are on the crap he sent me? Your backing the wrong horse.

Would you like to see my welding credentials? I was certified structural, and high pressure vessel. I have over 40 years fabrication experience with stick, MIG, and gas welding. I was certified in carbon arc, and burning.

Crapton's welds are erratic and cold. His welds look like bird****.

Now, where's your credentials?

|

Well three peaks? |

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 09:30 AM.

Links monetized by VigLink

|