Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

|

1 |

| 2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 9 |

10 |

11 |

12 |

13 |

14 |

15 |

| 16 |

17 |

18 |

19 |

20 |

21 |

22 |

| 23 |

24 |

25 |

26 |

27 |

28 |

29 |

| 30 |

31 |

|

|

|

|

|

|

CC Advertisers

CC Advertisers

|

|

1Likes 1Likes

-

1

Post By eschaider

1

Post By eschaider

06-12-2018, 10:24 AM

|

|

CC Member

|

|

|

Join Date: Aug 2017

Location: State College,

PA

Cobra Make, Engine:

Posts: 30

|

|

Not Ranked

Not Ranked

351W Engine Install, Driveline Alignment and Clearance Questions

351W Engine Install, Driveline Alignment and Clearance Questions

We made some headway this weekend on the engine install, or at least learned of the upcoming challenges we will face and time to make modifications.

Let me preface, this is the first time doing an engine install so some of my questions may be elementary...

A few notable things I found and curious what others have to say:

1. My Ford 8.8 rear differential mounts tires symmetrically and centered to the frame side to side yet, the center point of the differential for the drive shaft is 7/16" to the passenger side. The laser is shooting down the center of the tunnel in the picture (below).

2. The engine mounts we purchased from Summit are Prothane Motion Control mounts 6-503 which have a different mount location slightly in both vertical and horizontal dimensions then the old worn out mounts that came with my 351W block. It lowers the engine another inch which I think will help for clearance overall.

3. The engine to frame mounting brackets provided with my kit were not the right hole location or front to back location to mount the engine so we mocked up some out of foam board that we plan to have made. (see pic below)

So questions I would love to hear feedback on:

1. I plan to mount the engine at a -2 degree and plan to do the same with the diff for proper pinion angle. Should i center the driveline down the tunnel or should I offset it slightly toward the passenger side to address driveline offset along with the diff?

2. Clearances: I realize everything is tight! I have to shorten the alternator belt so alternator clears, either mount oil filter remotely or flip down 90 degrees, my clutch fork hits the frame, and the starter part of the bellhousing on passenger side is roughly 3/4" from frame. So tight in all four corners. How much clearance should I safely leave between bellhousing and frame?

3. Ground clearances, If I mount the engine centered with a -2 angle where I think I want it, I have front crossbar frame by radiator ground clearance 9.5", engine oil sump ground clearance 9.5", bellhousing clearance 8", rear diff ground clearance 7". Does this draw any concern from others, or how do your cars compare? I realize the bellhousing between axles is my main concern.

4. Driveline info: I have a 351W, Lakewood bellhousing, and toploader 4 speed transmission. Based on the kit provided tranny mount plate and poly tranny iso mount, my transmission output shaft centerline is 15.25" from ground, while my differential centerline for shaft is 11.5". Is a 3.75" drop over 23" driveshaft length and a 7/16" shift right to left, is this similar to other setups?

5. I am hoping to go with a mechanical clutch, but may have to do some homework to setup a different clutch fork and pivot location for more clearance. I wonder about getting the fork that actually pulls forward instead of rearward where the forward direction has more clearance, and have the pivot ball on the far side (passenger) of the bellhousing.

|

06-12-2018, 10:28 AM

|

|

CC Member

|

|

|

Join Date: Aug 2017

Location: State College,

PA

Cobra Make, Engine:

Posts: 30

|

|

Not Ranked

Not Ranked

pics for last post

pics for last post

I uploaded 4 images to go with the post that didnt arrive, let me try again  |

06-12-2018, 11:15 AM

|

|

CC Member

|

|

|

Join Date: Aug 2013

Location: Canandaigua,

NY

Cobra Make, Engine: SPF MKII Riverside Racer FIA

Posts: 2,505

|

|

Not Ranked

Not Ranked

The tail of the transmission and the differential can be off a few degrees left to right, what is more important is that they are in the same plane up and down.

Looking at the pictures you are going to need a remote oil filter. It does not look like you will have enough clearance with the frame to be able to change that oil filter without pulling the engine. Give it a try and see if you can remove the oil filter and re-install it again.

Jim

__________________

|

06-12-2018, 12:03 PM

|

|

Seasoned Member

|

|

|

Join Date: Apr 1999

Location: Portsmouth,

VA

Cobra Make, Engine: Unique 427 S/C, Dart 427W "Replica" Ford engine

Posts: 584

|

|

Not Ranked

Not Ranked

MOFO;

I used the exact same motor mounts on my Dart block (351) but when I tried to hook up the side pipes my header flanges and side pipe flanges were 1.5" apart and I couldn't bridge the gap. I'm running AFR 205 heads so the exhaust ports are a little higher than normal but most of it was from the mounts. I went back to a stock-type mount and that got the flanges much closer; I got the rest by SLOWLY tightening the flange bolts a little at a time over days. The first time I started it I was able to pull the hot pipes to fit. Not saying you'll have the same problem, but if you do...

Bill

|

06-12-2018, 02:16 PM

|

|

CC Member

|

|

|

Join Date: Feb 2014

Location: White City,

SK

Cobra Make, Engine: West Coast, 460 CID

Posts: 2,915

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by 1795

The tail of the transmission and the differential can be off a few degrees left to right, what is more important is that they are in the same plane up and down.

Looking at the pictures you are going to need a remote oil filter. It does not look like you will have enough clearance with the frame to be able to change that oil filter without pulling the engine. Give it a try and see if you can remove the oil filter and re-install it again.

Jim |

I disagree. Don't go remote unless you need to - there are more points to leak and more fittings that will reduce your oil flow unless you go with large lines.

While you can use a shorter oil filter, I believe a better solution is a Ford Performance 90° oil filter adapter, p/n M-6880-A50. You mount it to the block and can rotate it 360° before locking it down in the desired position. When I replaced the remote filter on mine with one of these adapters the cold start oil pressure went up 20 PSI - that's how much restriction there can be in a remote oil filter.

https://performanceparts.ford.com/part/M-6880-A50

Here's a photo:

EDIT: BTW, these are widely available - I got mine from Summit Racing.

__________________

Brian

Last edited by cycleguy55; 06-12-2018 at 02:22 PM..

|

06-12-2018, 02:36 PM

|

|

CC Member

|

|

|

Join Date: Aug 2013

Location: Canandaigua,

NY

Cobra Make, Engine: SPF MKII Riverside Racer FIA

Posts: 2,505

|

|

Not Ranked

Not Ranked

Ok, I can concede to Brian's suggestion about using the adapter. I just wanted to make sure that you realized that just because it fits in with the oil filter in place does not mean that you will be able to remove and replace the filter later. It takes a lot more room than we think. I had to play around for a while with my remote filter to find a place that would allow for enough room to remove the filter. If you do go with a remote, do not use any 90 degree fittings in the oil lines, they reduce oil flow a lot and may contribute to high oil pressure. Use 45 degree or straight fittings.

Jim

__________________

|

06-12-2018, 03:31 PM

|

|

CC Member

|

|

|

Join Date: Feb 2014

Location: White City,

SK

Cobra Make, Engine: West Coast, 460 CID

Posts: 2,915

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by 1795

Ok, I can concede to Brian's suggestion about using the adapter. I just wanted to make sure that you realized that just because it fits in with the oil filter in place does not mean that you will be able to remove and replace the filter later. It takes a lot more room than we think. I had to play around for a while with my remote filter to find a place that would allow for enough room to remove the filter. If you do go with a remote, do not use any 90 degree fittings in the oil lines, they reduce oil flow a lot and may contribute to high oil pressure. Use 45 degree or straight fittings.

Jim

|

I second what Jim wrote. IF you go with a remote oil filter don't use anything smaller than -10AN and avoid 90° fittings if at all possible to avoid restriction and pressure drop. If you need to use 90° fittings you may consider going to -12AN. So-called 'full-flow' fittings are available, and may be worth looking for.

__________________

Brian

|

06-13-2018, 05:49 AM

|

|

CC Member

|

|

|

Join Date: Aug 2017

Location: State College,

PA

Cobra Make, Engine:

Posts: 30

|

|

Not Ranked

Not Ranked

cycleguy 55,

Thats good to know on the 90 filter. I already had it in my cart at Summit, but Im glad to know you can rotate it 360 and have options. IF the 90 was straight up and down it could run filter towards the block and sump. I also see I can get an oil filter that is an inch shorter which should help. The oil filter setup I feel I have plenty of options.

Im most concerned about driveline alignment and clutch fork clearance.

|

06-13-2018, 06:17 AM

|

|

CC Member

|

|

|

Join Date: Aug 2017

Location: State College,

PA

Cobra Make, Engine:

Posts: 30

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by 1795

The tail of the transmission and the differential can be off a few degrees left to right, what is more important is that they are in the same plane up and down.

|

Jim, when you say in the same plane up and down, don't many vehicles especially higher clearance vehicles like trucks have a downward sloping rear drive shaft from transmission to rear diff? Is the same plane ideal but often not achieved?

Also, if I am using the tranny mount from CR, and a Ford 8.8 rear which is commonly used in these cars, and have 3.75" difference (tranny at 15.25", diff at 11.5") wouldnt mosts car builds end up in a similar predicament? I dont see any way to close that gap? Lowering the engine any more would have the bellhousing with limited ground clearance. Its at 8 inches now. So I could lower the engine 2, maybe 3", bellhousing would be at 5" ground clearance, and I would have to make some spacer bushings that drop the tranny mount the same amount. Have others done this? If I go much lower, my engine mounts and bolts would be down inside the frame rails. Dont have headers yet to see how they would be impacted.

Here is a sketch of where I am at currently: |

06-13-2018, 08:11 AM

|

|

CC Member

|

|

|

Join Date: Aug 2013

Location: Canandaigua,

NY

Cobra Make, Engine: SPF MKII Riverside Racer FIA

Posts: 2,505

|

|

Not Ranked

Not Ranked

What I meant by being in the same plane is that you should be able to draw a straight line between the two yokes. A downward slope from the tail of the transmission to the differential is fine and is quite typical. What you do not want is the tail of the transmission sloping upwards and the differential at neutral or sloping downwards. You want to avoid any compound angles in the universal joint. Use a level. If both ends are level, but one is lower than the other, that is fine.

__________________

|

06-14-2018, 11:52 AM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Gilroy,

CA

Cobra Make, Engine: SPF 2291, Whipple Blown & Injected 4V ModMotor

Posts: 2,738

|

|

Not Ranked

Not Ranked

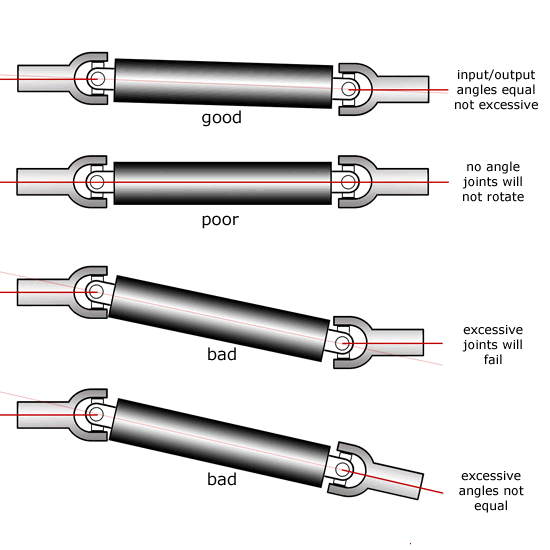

This pic might help you as you lay out your drive train;

While played out is a single plane, above, this alignment technique must be used in both the vertical and horizontal planes.

You do not want the drive train to be in a straight line. The universal joints or the CV joint (if you go that route) will fail. Both require a small misalignment but parallel input and output shafts in both the horizontal and vertical planes.

The easiest way to explain this is the tail shaft centerline and the pinion gear centerline need to be parallel to one another but not in a straight line.

Hope this helps.

Ed

__________________

Help them do what they would have done if they had known what they could do.

Help them do what they would have done if they had known what they could do.

|

06-14-2018, 01:37 PM

|

|

CC Member

|

|

|

Join Date: Aug 2013

Location: Canandaigua,

NY

Cobra Make, Engine: SPF MKII Riverside Racer FIA

Posts: 2,505

|

|

Not Ranked

Not Ranked

Ed,

Thank you so much! That is what I was trying to say, the pictures make it so much more understandable.

Jim

__________________

|

06-14-2018, 02:54 PM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Gilroy,

CA

Cobra Make, Engine: SPF 2291, Whipple Blown & Injected 4V ModMotor

Posts: 2,738

|

|

Not Ranked

Not Ranked

I know what you mean Jim. I can't tell you how many times I have tried to describe this without pics only to get that look that tells you that your explanation never cleared the bar. It is not that complicated but the pics sure do help. I scarfed those off the internet a few years ago because of their clarity. Whoever did them was good at keeping simple things simple.

Ed

__________________

Help them do what they would have done if they had known what they could do.

Help them do what they would have done if they had known what they could do.

|

06-17-2018, 09:26 PM

|

|

CC Member

|

|

|

Join Date: Aug 2017

Location: State College,

PA

Cobra Make, Engine:

Posts: 30

|

|

Not Ranked

Not Ranked

Thanks for input gents...

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 01:11 AM.

Links monetized by VigLink

|