Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

|

1 |

| 2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 9 |

10 |

11 |

12 |

13 |

14 |

15 |

| 16 |

17 |

18 |

19 |

20 |

21 |

22 |

| 23 |

24 |

25 |

26 |

27 |

28 |

29 |

| 30 |

31 |

|

|

|

|

|

|

CC Advertisers

CC Advertisers

|

|

4Likes 4Likes

-

2

Post By Tom Kirkham

2

Post By Tom Kirkham

-

1

Post By Tom Kirkham

1

Post By Tom Kirkham

-

1

Post By Gaz64

1

Post By Gaz64

11-18-2015, 09:28 PM

|

|

CC Member / Sponsor

|

|

|

Join Date: Jan 2002

Location: Provo,

UT

Cobra Make, Engine: HiTech Legends GT500

Posts: 1,359

|

|

Not Ranked

Not Ranked

MSD 6530 with throttle postion sensor

MSD 6530 with throttle postion sensor

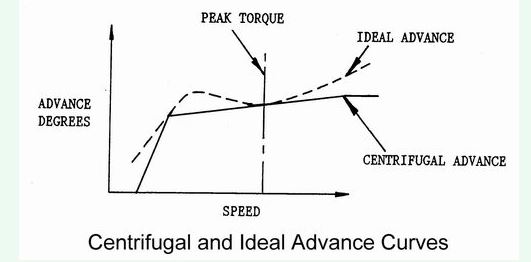

I have been working on a McLaren M6GT replica and came up with a solution to a problem I have had for many years. The problem has been how to get a vacuum advance curve on a non-vacuum advance distributor.

The 289 and 427 Ford engines that were used in Cobras and Gt40s of the sixties did not have vacuum advance. The engineers at Ford did not think that race engines needed vacuum advance and deleted it. This lack of vacuum advance causes problems for engines when driven on the street.

1. Hurts fuel economy

2. Higher engine temperatures especially the exhaust system.

3. Hurts throttle response

One solution to the problem is MSD E-distributor. It works great, and does not have the “ugly vacuum advance can” on it. Problem is the E-distributors are not made for the 427 engine. Another issue is the timing is not very adjustable.

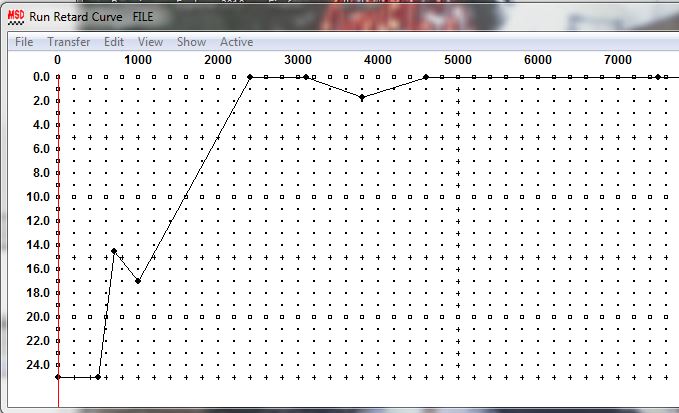

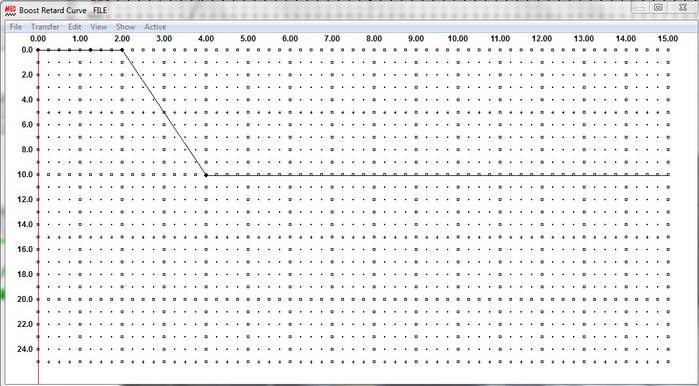

MSD also makes a couple of programmable spark boxes. The 6AL-2 Programmable, part number 6530 is designed to work on the street and is less expensive than the 7. The advance curve (actually it is really a retard curve, as the distributor is locked out at the highest timing point) is programmable with up to 32 discreet points along the RPM range. Another and key point of this box is the advance curve can be enhanced by using a MAP (Manifold Absolute Pressure) sensor. Hot Rodders running superchargers and turbochargers have been using the 6530 to retard the spark timing under boost, and running high advance under cruise. This has greatly helped their fuel mileage, engine temperatures and drivability.

BUT, what if you can’t get access to a vacuum source like on a Weber set up?

Take for example the McLaren M6GT I am working on. The engine is a 400 CID SBC. Aluminum block heads etc. with Weber 48 IDA Carbs. The engine was just not impressive at the low end. Even worse, due to the 3.22 ring and pinion gear and a 2.23 first gear ratio, and a 3 disc Tilton clutch, starting from stop was not fun, and starting on a uphill was almost impossible. The Weber carbs also created another problem. Where to get a vacuum source to run the MAP? We thought about drilling the manifold and tee-ing all of the lines together in a can, but it would look ugly, not to mention hurting the value of the manifold.

With EFI and IR (Individual Runner) or stack injection, MAP sensors do not work very well. The problem is the MAP sensors are too erratic with all of the pulses from the individual runners. Accumulator cans have been tried to smooth out the pulses, with some success, but I have not seen much success with bigger cams. Most people have found that alpha-N (alpha=throttle position, N=RPM) systems are much easier to tune on big lumpy race cams and IR manifolds. With this thought in mind I figured exchanging a TPS (Throttle Position Sensor) sensor for a MAP would be a viable alternative to controlling the spark timing with the MSD6530. While at SEMA I talked with a couple of MSD's techs about using a TPS instead of a MAP sensor. They told me “No it won’t work.” I explained to him alpha-N EFI systems, and that I wanted to try this with the MSD spark box. He gave me the look, like I was wasting his time…

So:

What I wanted:

1. Timing at about 5 degrees while the starter is engaged.

2. Timing at about 20 degrees at idle because of the camshaft overlap.

3. Timing at about 40 degrees under no load at idle.

4. Timing at full advance (all in) at 2,400 RPMs

5. 35 degrees total advance at full load i.e. WOT.

6. To slightly retard the timing at the RPM the torque peaks, to help prevent detonation.

7. Use the timing to help stabilize idle RPM, and help avoid engine stalling.

Basically I was trying to get a more theoretical optimum advance curve.

The limitations:

1. The MSD 6530 can only retard the spark a total of 30 degrees.

2. The running retard (RPM dependent) curve can only be retarded 25 degrees

3. The MAP signal can only retard spark

As you can see with the 30 degree limitation, there will have to be some compromises. For example 40 degrees idle spark timing – 5 degrees start timing gives a spread of 35 degrees. Actually it is worse, since I needed to set the base (or locked out) spark timing at 45 degrees. So 45 degrees -30 degrees = 15 degrees. So 15 degrees is the lowest spark timing I can have. This is a little bit more spark timing than I wanted, but ended up working out OK.

Here is the spark retard map based on RPM that I came up with:

It just so happens that the MAP sensor and TPS sensor connectors are interchangeable. Seems like the GM engineers where planning for this.

Here is the TPS vs spark retard map I came up with.

The TPS is labeled in pressure because the ECU thinks the TPS is a MAP sensor. The TPS at closed throttle reads 2 PSI. At quarter throttle the TPS sensor read 4 PSI. At closed throttle I wanted the ECU to not retard the timing at all. This would give me maximum ignition advance. This would also correlate to a high manifold vacuum. At quarter throttle I figured that the manifold vacuum would be nearly zero and so I set up this point where I would have maximum spark retard for the TPS. I am sure that a linear curve is not ideal, but it was quick. Remember the MSD technicians said this would not work… I got a start retard by hooking up the launch retard switch to activate during starter engagement to get the full 30 degrees of available timing retard.

The results:

The drivability was greatly improved. Starting on a hill is now a no drama affair. Throttle response and power are much, much better. So much so that it seemed to be a totally different engine. I have no data yet about fuel economy or exhaust temperatures. Maybe when the weather breaks...

Last edited by Tom Kirkham; 11-21-2015 at 09:40 PM..

Reason: grammer

|

11-18-2015, 10:53 PM

|

|

CC Member

|

|

|

Join Date: Dec 2010

Location: Tempe,AZ-High Point,NC,

AZ

Cobra Make, Engine: Kirkham #684, 482FE, Mike Mccluskey build

Posts: 2,520

|

|

Not Ranked

Not Ranked

You should forward this to the MSD techs, lol...

__________________

PRIDEnJOY

|

11-19-2015, 05:41 PM

|

|

CC Member

|

|

|

Join Date: Dec 2003

Location: Gurnee,

IL

Cobra Make, Engine: Kirkham #259

Posts: 1,396

|

|

Not Ranked

Not Ranked

Tom

Excellent ......and great thinking out of the box......good deal....

__________________

Morris

|

11-20-2015, 11:26 AM

|

|

CC Member

|

|

|

Join Date: Feb 2008

Location: Cleveland,

UK

Cobra Make, Engine: #535 Kirkham 427, 427 Side Oiler

Posts: 157

|

|

Not Ranked

Not Ranked

Tom,

This makes very interesting reading! I'm wondering if this is something I can try with by new 468 Shelby Stroker which also has driveability issues due it's big cam and 108LSA. I do need to work on the carbs because it is leaning out at no load part throttle which causes severe surging, but I think the MSD 6530 + MAP sensor will allow me to play with the advance curve as well. What do you think?

Thanks

Stuart

|

11-20-2015, 02:34 PM

|

|

CC Member / Sponsor

|

|

|

Join Date: Jan 2002

Location: Provo,

UT

Cobra Make, Engine: HiTech Legends GT500

Posts: 1,359

|

|

Not Ranked

Not Ranked

Stuart,

The MSD 6530 has a nice feature in that it will average the manifold air pressure signal over 2, 4 or six engine revolutions. This should help in smoothing out an erratic manifold air pressure signal. If this does not help enough, then I would suggest trying a TPS.

Another thing to notice is that at 1,000 RPMs I have a little v-notch in the timing curve. This notch also helps stabilize the idle, as well as help off idle drivability. This notch BTW is not possible with most non electronic distributors.

If the centrifugal advance springs are too light, they can lead to surging ...

|

11-20-2015, 02:54 PM

|

|

CC Member

|

|

|

Join Date: Dec 2003

Location: Gurnee,

IL

Cobra Make, Engine: Kirkham #259

Posts: 1,396

|

|

Not Ranked

Not Ranked

Tom

You and I have talked about this a few times .... but all of our Race cars and KMP259 have locked down Distributors and we set the timing at full advance from the start. However we use the MSD Start Retard unit to retard the timing below 800 rpm's..... we retard the timing I think it is 25*degrees ....from 36*degrees.....so at start it's starting at 11*degrees and then goes full to 36*degrees as the rpm's go over 800 rpm's.... this is how we have set all of our race motors and it has worked well for 30 years..... even though we are using a magnetic pick-up on the crank or the distributor on the motor.... but one thing is that we always have a dry sump system so there is no load on the distributor and it can respond freely.... and operating a motor at partial throttle is very important in Road Racing....

__________________

Morris

|

11-20-2015, 04:36 PM

|

|

CC Member / Sponsor

|

|

|

Join Date: Jan 2002

Location: Provo,

UT

Cobra Make, Engine: HiTech Legends GT500

Posts: 1,359

|

|

Not Ranked

Not Ranked

A great read with lots of information.

Calibration guides |

11-20-2015, 05:49 PM

|

|

CC Member

|

|

|

Join Date: Dec 2003

Location: Gurnee,

IL

Cobra Make, Engine: Kirkham #259

Posts: 1,396

|

|

Not Ranked

Not Ranked

Seems like every time I read these articles ....I have ahha moments....and my brain gains more of a understanding of what's going on with the motor or car.....

Thanks for the article....

Morris

__________________

Morris

|

11-21-2015, 07:33 AM

|

|

CC Member

|

|

|

Join Date: Feb 2008

Location: Cleveland,

UK

Cobra Make, Engine: #535 Kirkham 427, 427 Side Oiler

Posts: 157

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Tom Kirkham

Stuart,

The MSD 6530 has a nice feature in that it will average the manifold air pressure signal over 2, 4 or six engine revolutions. This should help in smoothing out an erratic manifold air pressure signal. If this does not help enough, then I would suggest trying a TPS.

Another thing to notice is that at 1,000 RPMs I have a little v-notch in the timing curve. This notch also helps stabilize the idle, as well as help off idle drivability. This notch BTW is not possible with most non electronic distributors.

If the centrifugal advance springs are too light, they can lead to surging ...

|

Hi Tom,

I'm using the 'blue' springs in my MSD distributor - not the lightest, but stability of the advance from idle up to max has crossed my mind. A tell tale sign is the fact I cannot determine the advance at idle with the strobe. The line dances around a lot. Beyond 3k rpm it's fine and stays bang on 36 degrees. I think the 6AL-2 + MAP sensor will give many benefits.

I have 2x4 600CFM Quickfuel carbs sitting on a Blue Thunder dual plane inlet manifold. There is a 1/2" NPT plug in the back of the manifold which is not used and seems the ideal position to install the MAP sensor. Can you recommend a sensor that would fit and not look too out of place in period looking Cobra 427 engine bay?

I can lock out my MSD distributor so should be no problem upgrading my MSD 6AL box to the 6AL-2?

I'm also planning to get an Innovate LM-2 for the carb tuning so that I can get the A/F correct (or as near it can be), for all or most driving conditions.

Thanks

Stuart

|

11-21-2015, 08:30 AM

|

|

CC Member / Sponsor

|

|

|

Join Date: Jan 2002

Location: Provo,

UT

Cobra Make, Engine: HiTech Legends GT500

Posts: 1,359

|

|

Not Ranked

Not Ranked

The blue springs have typically not been a problem. However they don't let the advance come in as fast as I would like it.

The MAP sensor can be hidden out of sight. Just run a vacuum hose over to it.

The MAP sensor is just a generic GM sensor. Due to emissions laws, all of them seem to be good. The connectors are Weatherpack. You will want a MAP sensor that is rated for 1 atmosphere.

With the O2 sensors you should be able to dial your system in very quickly.

|

11-21-2015, 10:14 AM

|

|

CC Member

|

|

|

Join Date: Feb 2008

Location: Cleveland,

UK

Cobra Make, Engine: #535 Kirkham 427, 427 Side Oiler

Posts: 157

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Tom Kirkham

The blue springs have typically not been a problem. However they don't let the advance come in as fast as I would like it.

The MAP sensor can be hidden out of sight. Just run a vacuum hose over to it.

The MAP sensor is just a generic GM sensor. Due to emissions laws, all of them seem to be good. The connectors are Weatherpack. You will want a MAP sensor that is rated for 1 atmosphere.

With the O2 sensors you should be able to dial your system in very quickly.

|

Thanks Tom,

Great information & advice. Really helpful!

Regards

Stuart |

11-21-2015, 10:31 AM

|

|

CC Member / Sponsor

|

|

|

Join Date: Jan 2002

Location: Provo,

UT

Cobra Make, Engine: HiTech Legends GT500

Posts: 1,359

|

|

Not Ranked

Not Ranked

MAP vs TPS

MAP vs TPS

|

11-21-2015, 02:37 PM

|

|

CC Member

|

|

|

Join Date: Jun 2015

Posts: 136

|

|

Not Ranked

Not Ranked

Would it be possible too use a joint signal from both map and tps?

|

11-21-2015, 05:57 PM

|

|

CC Member / Sponsor

|

|

|

Join Date: Jan 2002

Location: Provo,

UT

Cobra Make, Engine: HiTech Legends GT500

Posts: 1,359

|

|

Not Ranked

Not Ranked

Not with the MSD 6530. Not easily, at least not that I know of. A control board could be made, that would send a signal to the MSD unit. The signal could be based on a look up table...Probably easier and cheaper to buy a EFI setup and not use the fuel injection. Or possibly use a Megajolt system.

Modern fuel injection systems do use both. The TPS is used to control enrichment during rapid throttle movement, like an accelerator pump on a carb.

Some Alpha-N systems will use a MAP sensor to correct for barometric pressure.

|

01-01-2016, 12:56 PM

|

|

CC Member

|

|

|

Join Date: Feb 2008

Location: Cleveland,

UK

Cobra Make, Engine: #535 Kirkham 427, 427 Side Oiler

Posts: 157

|

|

Not Ranked

Not Ranked

Hi Tom,

I've decided to upgrade my ignition to the programmable MSD 6AL-2 (6530) and I have a few questions about setting up the timing following your initial thread. I've PM'd you the questions. I'd very much appreciate your advice.

Many thanks

Stuart

|

01-01-2016, 02:55 PM

|

|

CC Member / Sponsor

|

|

|

Join Date: Jan 2002

Location: Provo,

UT

Cobra Make, Engine: HiTech Legends GT500

Posts: 1,359

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by A98Coupe

Hi Tom,

I've decided to upgrade my ignition to the programmable MSD 6AL-2 (6530) and I have a few questions about setting up the timing following your initial thread. I've PM'd you the questions. I'd very much appreciate your advice.

Many thanks

Stuart

|

Answered. |

01-25-2016, 09:56 PM

|

|

CC Member

|

|

|

Join Date: May 2008

Location: Brisbane,

QLD

Cobra Make, Engine:

Posts: 2,797

|

|

Not Ranked

Not Ranked

Hi Tom,

I have used an MSD 6530 on one of my previous cars.

I didn't have the success I wanted in a few areas.

I have now found a much better system:

https://www.cbperformance.com/Produc...oductCode=2013

Note that is has a 21 x 21 fully programmable table where you set the boundaries of map and rpm. Completely user adjustable, on the fly.

A great product.

__________________

Gary

Gold Certified Holden Technician

|

01-25-2016, 11:29 PM

|

|

CC Member

|

|

|

Join Date: Apr 2012

Location: Bay Area (Peninsula),

CA

Cobra Make, Engine: ERA 427, 427/487 side-oiler

Posts: 1,248

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Morris

Tom

You and I have talked about this a few times .... but all of our Race cars and KMP259 have locked down Distributors and we set the timing at full advance from the start. However we use the MSD Start Retard unit to retard the timing below 800 rpm's..... we retard the timing I think it is 25*degrees ....from 36*degrees.....so at start it's starting at 11*degrees and then goes full to 36*degrees as the rpm's go over 800 rpm's.... this is how we have set all of our race motors and it has worked well for 30 years..... even though we are using a magnetic pick-up on the crank or the distributor on the motor.... but one thing is that we always have a dry sump system so there is no load on the distributor and it can respond freely.... and operating a motor at partial throttle is very important in Road Racing....

|

I was having a plug fouling problem I couldn't solve, and the solution I eventually found was to use far more initial advance than stock. The two approaches I considered were (1) a programmable MSD box, and (2) a 10 degree bushing from 4secondsflat.com. I went with the bushing because it's simpler. So now I have 26 degrees of initial timing, and 36 degrees at full advance.

Wondering if I'd benefit from pseudo-vacuum advance, through a programmable MSD box either with or without TPS/MAP.

|

01-26-2016, 11:30 PM

|

|

CC Member

|

|

|

Join Date: May 2008

Location: Brisbane,

QLD

Cobra Make, Engine:

Posts: 2,797

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by lippy

Wondering if I'd benefit from pseudo-vacuum advance, through a programmable MSD box either with or without TPS/MAP.

|

All engines can benefit, just be wary of rotor phasing.

Some are easier than others, I've used the MSD product, and although I found it "useable", not even close to my new one from CB Performance.

__________________

Gary

Gold Certified Holden Technician

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 04:29 AM.

Links monetized by VigLink

|