Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| 1 |

2 |

3 |

4 |

5 |

6 |

7 |

| 8 |

9 |

10 |

11 |

12 |

13 |

14 |

| 15 |

16 |

17 |

18 |

19 |

20 |

21 |

| 22 |

23 |

24 |

25 |

26 |

27 |

28 |

| 29 |

30 |

31 |

|

|

|

|

|

CC Advertisers

CC Advertisers

|

|

7Likes 7Likes

-

4

Post By Dan Case

4

Post By Dan Case

-

3

Post By Dan Case

3

Post By Dan Case

04-12-2022, 09:36 AM

|

|

CC Member

|

|

|

Join Date: Mar 2009

Location: Mendota,

IL

Cobra Make, Engine:

Posts: 697

|

|

Not Ranked

Not Ranked

Leaf spring wheel alignment

Leaf spring wheel alignment

I need to keep my scratch build moving forward. What specs should I be shooting for on the alignment on rear of a leaf spring car. I would like specs for street use and open track.

My rear suspension will be nonadjustable as on an original car. I need to get a rear spring built. The length needs to be right for the camber curve.

It would be very helpful if some could give me the center-to-center measurement of the rear shock mounting bolts. This measurement needs to be as it sits on the ground just like it is driven. I dont know if its even possible to get this measurement as the car sits.

Also what shape is the leaf spring in the on the ground driving state? Is it straight or flat, curved upward, or curved downward .

With the length between the shock mounting bolts and the shape of the rear spring, with the alignment specs. I should be able to calculate the correct spring length I need to have made.

I sure would be nice to get it right the first time. Custom made springs are not cheap if you dont get it right.

Thanks guys if you can help. Mark

|

04-12-2022, 03:17 PM

|

|

CC Member

|

|

|

Join Date: Oct 2020

Location: New Haven,

ct

Cobra Make, Engine: Factory Five

Posts: 26

|

|

Not Ranked

Not Ranked

springs

springs

I don't know if this will post. if not I think they are posted in my photo gallery. Insert Photos and Images |

04-13-2022, 12:05 AM

|

|

CC Member

|

|

|

Join Date: Apr 2005

Location: Tucson,

AZ

Cobra Make, Engine:

Posts: 5,391

|

|

Not Ranked

Not Ranked

Depending on how accurate to original the chassis and suspension is, the original measurements could be used and are listed in the chassis manual. I don't recall what the eye to eye length is off the top of my head but if you don't have a manual, I can look it up and post it.

Larry

__________________

Alba gu bràth

|

04-13-2022, 07:35 AM

|

|

CC Member

|

|

|

Join Date: Mar 2009

Location: Mendota,

IL

Cobra Make, Engine:

Posts: 697

|

|

Not Ranked

Not Ranked

Rustyrims Thank you. I have that drawing from AC. I have several different drawing. Unfortunately there is more than one length of spring. If you change the spring length by only 1/8 inch it changes the camber.

Larry Yes what you said is true but those alignment specs might not be ideal for street and open track. Weight will affect ride height and that will change camber. Tire dia will change ride height but not suspension geometry. I doubt 2 ac cars built one after another had the same alignment specs. Close but not perfect.

.

I got ahold of Kirkham asked about a rear spring. They said they got some in and would sell one. $995.00 Plus Tax and shipping. They could not tell me the flat length. The flat length is something I need to know. They caution against using a nonadjustable lower control arm and all the pitfalls of them. They also said they have sold some springs to guys with original car that were used with some success.

I cant take a chance with a spring that some say will work. I have to have one made to a length that will work on my car. How close is my build to an original car? Who knows how close my plans are?

Now if I could only get a simple answer to these two simple questions.

1 Can anyone give me a center to center measurement between the rear shock mounting bolts? Needs to be an original type car and on its tires, like it goes down the road.

2 When an original car is sitting on is tires. That is the shape of the rear spring? Is it fairly flat, curved upward, or curved downward?

If I can get the answers to these two questions, I can figure a spring length that will hopefully work. The spring length might even end up being the length mentioned in the cobra manual or one of the many different drawings out there.

Thanks again guys! Hopeful to get the answers I need!

Last edited by MAStuart; 04-13-2022 at 07:51 AM..

|

04-13-2022, 07:56 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Mar 2005

Location: Manchester,

NH

Cobra Make, Engine: AK1085 (302 Street), HTM111 (427 Comp), CSX2375R (289 Comp) and COB5999 (427 S/C)

Posts: 19,011

|

|

Not Ranked

Not Ranked

Phew,

This seems to be a loaded question as there are so many variables.

a) A-arm itself

b) Chassis / suspension variation

c) Tire and wheel combo

d) Spring articulation and rate

No?

Not sure that these cars were tweaked to such exacting standards as it seems to me the old way was a more Mike Tyson approach, go hard and do not break.

Did SAI truly set up specific adjustments on the earlier buggy cars and/or even the 427 chassis? My guess the 427 was far more adjustable and the 289 were more hold on and be fast and win?

Just trying to point out at some point the calculations might be better served with getting your car done using basic common sense. Remember the spring articulates as it compresses thus your camber changes depending upon the spring arch and its rate. I am somewhere around 1.5 (memory) but again, to make it perfect might be a huge challenge. However I am not that smart so I may be way off, Cobras were loaded with variation.

Last edited by 1985 CCX; 04-13-2022 at 01:18 PM..

|

04-13-2022, 12:23 PM

|

|

CC Member

|

|

|

Join Date: Apr 2004

Posts: 1,029

|

|

Not Ranked

Not Ranked

We have measured the wishbones front and rear for four original cars and they were very consistent. All the pieces were laid in fixtures for welding so there should not be a lot of variation.

I have measured the front halves of three chassis and except for what people did to them they were very consistent. Again, all the pieces were clamped into fixtures for welding.

We have measured the road springs also. The eye to eye distance with the main leaves held flat agrees with what A.C. published when the cars were new. The only variable in spring assemblies on a work bench beyond a few thousandths has been the in free camber. All the decades old springs had slightly less free camber than what A.C. described new.

In a period letter to a customer A.C. described how they used a long straight edge against brake rotors front and rear to test suspension alignment during assembly.

For factory road racing front spring main leaf pairs were shortened to obtain a camber the driver and crew desired within some kind of tolerance. For drag racing the lengths of both springs were changed to suit desired outcomes. I would imagine that those making “adjustments” as their every day job had a real good idea how a change in length X changed camber Y.

In well used cars it is not rare to find the four u-bolt holes in spring towers deformed, especially in any car that has been crashed. Deformed or wallowed holes allow users to install road springs crooked such that wheel base on one side is short and one is long. It also messes up other geometries. Shelby American’s racing solution was to put the springs exactly where they wanted them and then weld in hard stops to prevent the springs from twisting laterally on top of towers.

Front wishbones are not very strong and do not really need to be other than they flex easily. How easily, I straighten slightly deformed ones with some dowels and hand /arm pressure. Arms can be flexed and rod ends rotated to get back to factory dimensions in most cases. Shelby American stiffened racing ones by adding cross tubes to make triangles out of the assemblies. That stopped most of the flexible nature of the front wishbones.

There was another issue and that was sometimes the center bolt in a spring was not actually in the center of the eye to eye dimension. I have found that in two springs with offsets. Fortunately the clearance holes in towers are just that clearance holes. I was able to slide errant springs to one side or the other to get the eyes on each side equidistant from the frame.

Don’t forget that the whole chassis in an original Cobra is part of the “suspension”. If all four corners suspension parts were rock solid the chassis as originally made would be flexing all the time in between the corners. Many original car owners have added some type of sleeves full length of their main tubes. That change is a big one for original car dynamics.

Tires. Tires, street or race, before the 1970s were a serious limitation. A box stock street car could not get traction and race cars were not much better. To a point having more power or a better suspension would not have helped on hard rubber skinny tires. Whether the camber was exactly X° or X±1/2° was probably not an issue. I have an old note page from a privateer racer. He stopped if he got within ½° degree agreement between left and right sides front and rear. (Yes, people use to check and tweak caster and camber. One racer published a how to article to make small caster changes in Cobra suspensions front and rear in his club magazine long ago.)

One original Cobra box stock versus one with sleeved frame, hard stopped springs, triangulated front wishbones, custom stronger than anything Shelby’s works did roll bar system, and shorter front spring to get some negative camber as desired are very different on the road and the harder the cars are pushed the more different they behave.

__________________

Dan Case

1964 Cobra owner since 1983, Cobra crazy since I saw my first one in the mid 1960s in Huntsville, AL.

|

04-13-2022, 01:14 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Mar 2005

Location: Manchester,

NH

Cobra Make, Engine: AK1085 (302 Street), HTM111 (427 Comp), CSX2375R (289 Comp) and COB5999 (427 S/C)

Posts: 19,011

|

|

Not Ranked

Not Ranked

Dan knows best!

|

04-13-2022, 01:18 PM

|

|

CC Member

|

|

|

Join Date: Apr 2004

Posts: 1,029

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by 1985 CCX

Dan knows best!

|

Best? Not so sure about that. I do spend a lot of time analyzing original parts, materials, and methods. I have a pretty good handle on what A.C., Continental Cars, and Shelby American did for many but not all subjects.

On fabrication:

A.C. was pretty consistent in cutting out and forming parts. To make one set of repair parts we had to create a wing bender tool set to go from flat blanks to exact matches of what A.C. created. Making welding jigs for create exact fit replacement subassemblies was required also. A.C. sheared, punched, welded, and drilled with jig fixtures.

Shelby's works was not consistent in much of anything I have studied. Shelby’s crews hand sheared, sawed, filed, ground with a grinder, free hand drilled, free hand turret punched, and used a belt sander to shape and deburr parts such that some street and race parts were each a one of one piece. If it looks precise and pretty Shelby’s works probably did not do it. I have a collection of factory drawings Shelby American created for parts they provided. So far, I have found that you cannot use any one of them to make an accurate copy of what they made. The drawings are suggestions and in some cases their math does not work. The only one that has caused me problems is the levers the team made for Weber carburetors. The levers were saw cut from flat stock, if bending was required the piece was heated with a torch and manually bent, and connection holes were sometimes in good places and sometimes not. In comparing notes around I learned it is not uncommon to have to relocate a lever hole for one or two carburetors in a set of four between 0.005 and 0.020 inch to prevent binding and or get great flow balance. I moved a hole in one lever 0.005 to get the right rear carburetor in our 1964 works system to be free of binding and get the last bit of balanced flow at idle.

Machine work:

A.C. was very consistent. Since 1984 I have measured and reverse engineered an assortment of their small parts they made themselves. Part to part variability at 73°F and 50% RH is usually on the order of a few ten thousandths of an inch to maybe five thousandths of any inch depending on what the part was until a revision was made. I bought more and better measuring tools to measure as well as they made parts. Yes, designs and dimensions of some items changed over time and some might confuse a planned change as sloppy manufacturing. If I use the standard deviations I find in their parts as basis to set drawing tolerances they catch machinists’ attention as being very tight in many cases.

Shelby American: Not so precise but the only one I have had to do something about was for carburetor levers.

In general most of the fabrication and machine work A.C. did was very consistent and yes they made planned changes as required over time. The same could not be said for some of the items like coachwork suppliers provided. Shelby American parts were usually quite variable for some reason or another. One reason was in many cases what team Shelby American used and what was sold to customers was different a little to a lot. To be fair, Shelby’s folks changed many things on purpose every time or most every time because they wanted to. As topics, the two best fabrication examples are steel racing rocker arm covers and steel oil pans. Shelby American famously did their own fabrication of them and as a result there may not have been any two sets of rocker arm covers or any two steel oil pans exactly alike.

__________________

Dan Case

1964 Cobra owner since 1983, Cobra crazy since I saw my first one in the mid 1960s in Huntsville, AL.

Last edited by Dan Case; 04-13-2022 at 05:36 PM..

Reason: add detail

|

04-17-2022, 06:33 AM

|

|

CC Member

|

|

|

Join Date: Jun 2000

Location: Cape Town, South Africa/Mainz, Germany,

Posts: 1,601

|

|

Not Ranked

Not Ranked

Post #8 from Dan about Shelby reminds me how we work :-)

Eventually it all fits.

I have all the CSX 4000 drawings. One example of mis-fit is the assembly of LCA to rear upright. After the LCA was welded and coated I fit it to the upright. Only to find that there is a slight interference - with the weld if I remember correctly. Means grinding LCA - and powder coating it, again.

The idea was to save time while waiting for the uprights to come back from machining.

And sending all 4 (6) suspension parts for coating in the meantime.

While i am at it, the dampener spring perch can also cause an interference with the LCA (damper mount), if you don't get the exact damper. More grinding - and powder coating...

I spray paint parts now. With a can.

1.000 hours to build a CSX, instead of 275 hours? Easy...

__________________

If I don't respond anymore, that's because I can't log in

|

04-26-2022, 12:34 PM

|

|

CC Member

|

|

|

Join Date: Mar 2009

Location: Mendota,

IL

Cobra Make, Engine:

Posts: 697

|

|

Not Ranked

Not Ranked

I have been doing some mocking up on my chassis. Doing a lot of measuring. I have some numbers on how the camber curve works on the rear suspension. I asked a few simple questions that I never got an answer too.

1 When an original car is sitting on its tires, can the distance between the mounting bolts for the rear shocks be measured? I so what is the distance? I do not know if is even possible to get this measurement while the car is sitting on the ground.

2 What is the shape of the rear spring when it is sitting on its tires like i is driven. Is it flat, curved upwards, or curved downwards?

If you have any experience building one of these cars from scratch. You would know that the above question would be very helpful. The plans I am using I am told were taken from original cars. I also am very picky when I build things. If it calls for a certain measurement I don't make it close, I make it right on the measurement. I know how tolerances stack up. I know how welding pulls things around. Over the years I have learned to check all measurements on a drawing. I have also found many problems on drawings. It sucks spending 40 hours or more building a jig to make repeatable parts, only to later find mistakes on the part you want to make.

I asked about alignment specs. Yes the cobra manual has the specs. But can thee specs be better than the manual states. Yes that is why there is more than one set of drawing for the springs. You can bet the reason for making adjustable A arms is to get better alignment specs.

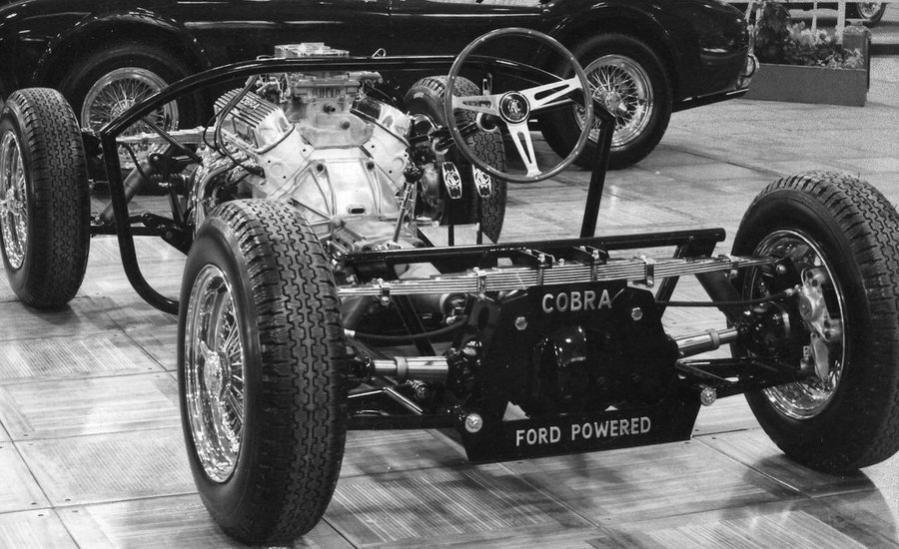

Anyhow I found this picture on the net.

I can only assume this is a show chassis. Being a show chassis, I assume it is sitting lower in the rear than would be normal. The rear spring has a small amount of upward bend. The rear spring must be weak because the chassis is missing a lot of weight. Also note the rear A arm inner pivit point is lower than the outer pivot point. The angle on the half shaft might be getting close to there max working angle. I also feel that if the wheel has to move upward much to go over bumps, the shocks would run out of travel. I looks like the rear has negative camber and the front has positive camber as the manual states.

Any thought on what you see?

|

04-26-2022, 01:11 PM

|

|

CC Member

|

|

|

Join Date: Apr 2004

Posts: 1,029

|

|

Not Ranked

Not Ranked

With the rear cockpit bulkhead panel removed there is lots of access to the upper rear shock absorber fixing locations.

Late chassis manual, page 12.

Caster = 7°

Camber (front) +1°

Toe In (front) = 1/16”

Camber (rear) -2°

Road racers normally changed front camber (shortened the front main leaf pair) to obtain their favorite negative value. Shelby drag cars changed lengths of both front and rear springs as they wished.

__________________

Dan Case

1964 Cobra owner since 1983, Cobra crazy since I saw my first one in the mid 1960s in Huntsville, AL.

Last edited by Dan Case; 04-26-2022 at 01:15 PM..

Reason: add detail

|

04-27-2022, 03:54 PM

|

|

CC Member / Sponsor

|

|

|

Join Date: Jan 2002

Location: Provo,

UT

Cobra Make, Engine: Daytona Coupe

Posts: 1,359

|

|

Not Ranked

Not Ranked

The proper thickness steel to build Cobra leaf springs is not readily available in the US. So either you change the spring's leaf count to get the spring rate you want, get the correct leaf count and get a stiff spring, or get springs out of England. The next issue is to find a spring maker who will forge in the correct taper and put in the correct shaped ends.

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 04:54 PM.

Links monetized by VigLink

|