Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

1 |

2 |

3 |

4 |

5 |

| 6 |

7 |

8 |

9 |

10 |

11 |

12 |

| 13 |

14 |

15 |

16 |

17 |

18 |

19 |

| 20 |

21 |

22 |

23 |

24 |

25 |

26 |

| 27 |

28 |

29 |

30 |

|

|

|

|

CC Advertisers

CC Advertisers

|

|

2Likes 2Likes

-

1

Post By 1795

1

Post By 1795

-

1

Post By patrickt

1

Post By patrickt

04-06-2016, 07:51 AM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: Wayland MA,

MA

Cobra Make, Engine: 289 ERA #2115 under build in my bedroom

Posts: 101

|

|

Not Ranked

Not Ranked

Best tool for Adj Lifters

Best tool for Adj Lifters

Hello All,

Looking for the best tool for adj solid lifters for SBF. LSM has a torque type set to 22lbs... with three T handles..... will this work for SBF ? Is it worth it ? thanks mike

|

04-06-2016, 08:13 AM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

Closed end wrench, T-handle, and feeler gauges.

I wouldn't bother with any of the frilly tools for setting lash.

|

04-06-2016, 08:21 AM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: Wayland MA,

MA

Cobra Make, Engine: 289 ERA #2115 under build in my bedroom

Posts: 101

|

|

Not Ranked

Not Ranked

ok ... sounds good thanks

|

04-06-2016, 09:55 AM

|

|

CC Member

|

|

|

Join Date: Apr 2012

Location: Bay Area (Peninsula),

CA

Cobra Make, Engine: ERA 427, 427/487 side-oiler

Posts: 1,248

|

|

Not Ranked

Not Ranked

Agree with Brent. What I do is set the lash *very slightly* looser than spec, tightening the nut with a closed-end wrench (snug, say roughly 10-15 ft-lb, by feel) while creating opposing force/holding the adjusting screw tight with a T-handle. Then I check the lash again. If things didn't move and it's still good, I then torque the nut with a good torque wrench. The two tightening steps, if I do them right, will close the lash a tiny bit (less than a thousandth) and I'll be spot on at the end.

|

04-06-2016, 10:16 AM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: Wayland MA,

MA

Cobra Make, Engine: 289 ERA #2115 under build in my bedroom

Posts: 101

|

|

Not Ranked

Not Ranked

Yes... I can see that the final ..torque would need to be checked, and I'll take the advise on how to lash it "slightly". thanks mike

|

04-06-2016, 01:35 PM

|

|

CC Member

|

|

|

Join Date: Aug 2013

Location: Canandaigua,

NY

Cobra Make, Engine: SPF MKII Riverside Racer FIA

Posts: 2,507

|

|

Not Ranked

Not Ranked

Make sure that you use a T-handle allen wrench instead of a standard allen wrench. The standard sized one is quite small and if you drop it there is the possibility of it falling down an oil channel  |

04-06-2016, 01:48 PM

|

|

Senior CC Premier Member

|

|

|

Join Date: Nov 2004

Location: SoCal,

CA

Cobra Make, Engine: CSX #4xxx with CSX 482; David Kee Toploader

Posts: 3,574

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by 1795

Make sure that you use a T-handle allen wrench instead of a standard allen wrench. The standard sized one is quite small and if you drop it there is the possibility of it falling down an oil channel  |

Yup! Then your least worries will be setting rockers!  T-handle for sure!

__________________

All that's stopping you now Son, is blind-raging fear.......

|

04-06-2016, 03:46 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,017

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by 289ERAkit

Hello All,

Looking for the best tool for adj solid lifters for SBF. LSM has a torque type set to 22lbs... with three T handles..... will this work for SBF ? Is it worth it ? thanks mike

|

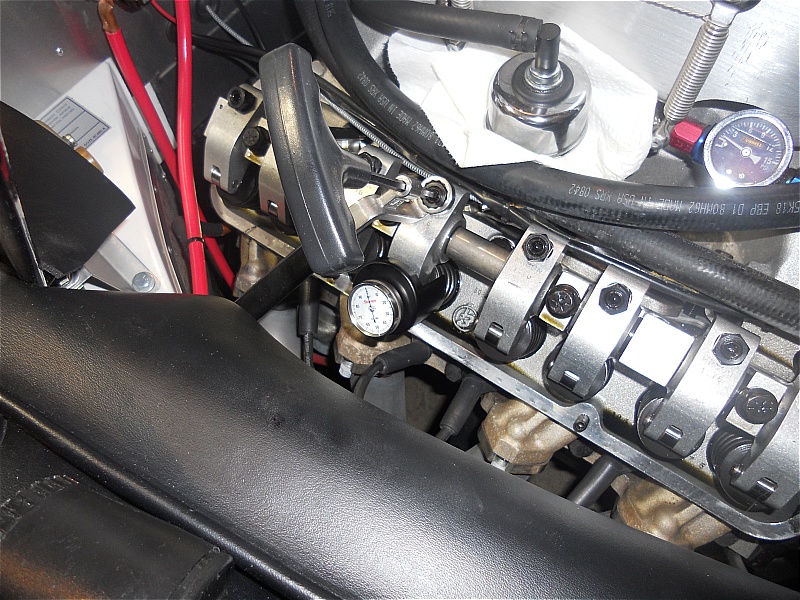

Uhhh, like my little valve gapper, discussed here: Valve cover gasket alternatives to cork

Last edited by patrickt; 11-08-2016 at 11:41 AM..

|

04-06-2016, 05:25 PM

|

|

CC Member

|

|

|

Join Date: Apr 2012

Location: Bay Area (Peninsula),

CA

Cobra Make, Engine: ERA 427, 427/487 side-oiler

Posts: 1,248

|

|

Not Ranked

Not Ranked

Get these: [ame="http://www.amazon.com/Bondhus-13390-T-handles-Stand-8-Inch/dp/B00012WYEC?ie=UTF8&keywords=bondhus%20allen%20wren ch%20set&qid=1459988597&ref_=sr_1_7&sr=8-7"]Bondhus 13390 Set of 10 Hex T-handles with Stand, sizes 3/32-3/8-Inch - Hex Keys - Amazon.com@@AMEPARAM@@http://ecx.images-amazon.com/images/I/41CPRQBTTVL.@@AMEPARAM@@41CPRQBTTVL[/ame]

When I do mine, I put rags around where I am working, so I don't drop something in. Sensitive subject for me, as I recently dropped a nut into my dizzy hole (that sounds naughty) and had to drop my pan to get it out.

|

04-06-2016, 05:37 PM

|

|

CC Member

|

|

|

Join Date: Aug 2013

Location: Canandaigua,

NY

Cobra Make, Engine: SPF MKII Riverside Racer FIA

Posts: 2,507

|

|

Not Ranked

Not Ranked

The time prior to my last valve lash adjustment I did not have the T-handles and while attempting to loosen the set adjuster the allen wrench slipped out of my slightly oily hand and almost went for a trip inside the head. Stopped right there after retrieving the wrench and went out and bought some T-handle wrenches, after changing my shorts of course...  No need to worry about that again. |

04-06-2016, 05:46 PM

|

|

CC Member

|

|

|

Join Date: May 2008

Location: Brisbane,

QLD

Cobra Make, Engine:

Posts: 2,797

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by lippy

Agree with Brent. What I do is set the lash *very slightly* looser than spec, tightening the nut with a closed-end wrench (snug, say roughly 10-15 ft-lb, by feel) while creating opposing force/holding the adjusting screw tight with a T-handle. Then I check the lash again. If things didn't move and it's still good, I then torque the nut with a good torque wrench. The two tightening steps, if I do them right, will close the lash a tiny bit (less than a thousandth) and I'll be spot on at the end.

|

Same for me.

And the same in reverse.

Some try to loosen the set screw rather than loosen the adjusting nut. |

04-06-2016, 06:05 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,017

|

|

Not Ranked

Not Ranked

I love to waste money on Cobra tools, but the one nice point of having that valve gapper is that you can watch the needle as you tighten it down -- and you can see how much you have to lean on the adjuster to compensate for the change in gap that comes with tightening it down. If you're building engines, and doing valves on a weekly basis, it's second nature. But when you only gap your valves once every year or so, having a gauge with a face and needle makes it easier.

|

04-06-2016, 07:13 PM

|

|

CC Member

|

|

|

Join Date: Apr 2012

Location: Bay Area (Peninsula),

CA

Cobra Make, Engine: ERA 427, 427/487 side-oiler

Posts: 1,248

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by patrickt

I love to waste money on Cobra tools, but the one nice point of having that valve gapper is that you can watch the needle as you tighten it down -- and you can see how much you have to lean on the adjuster to compensate for the change in gap that comes with tightening it down. If you're building engines, and doing valves on a weekly basis, it's second nature. But when you only gap your valves once every year or so, having a gauge with a face and needle makes it easier.

|

Yeah, but those tools are $200 if I remember correctly. And I bought a great Precision dual-beam torque wrench for less then that, and I can use it for the valve lash plus a ton of other things. |

04-07-2016, 10:27 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,017

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by lippy

Yeah, but those tools are $200 if I remember correctly. And I bought a great Precision dual-beam torque wrench for less then that, and I can use it for the valve lash plus a ton of other things.

|

That's why I call it wasting money.  |

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 09:42 AM.

Links monetized by VigLink

|