Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

1 |

2 |

| 3 |

4 |

5 |

6 |

7 |

8 |

9 |

| 10 |

11 |

12 |

13 |

14 |

15 |

16 |

| 17 |

18 |

19 |

20 |

21 |

22 |

23 |

| 24 |

25 |

26 |

27 |

28 |

29 |

30 |

|

CC Advertisers

CC Advertisers

|

|

3Likes 3Likes

-

1

Post By eschaider

1

Post By eschaider

-

2

Post By cycleguy55

2

Post By cycleguy55

09-25-2023, 08:28 AM

|

|

CC Member

|

|

|

Join Date: Jul 2022

Cobra Make, Engine:

Posts: 91

|

|

Not Ranked

Not Ranked

Ford Windsor 427 SB excessive oil pressure

Ford Windsor 427 SB excessive oil pressure

Hi All

Iím at a pickle with my new ford racing 427 sb crate engine.

I finished dressing the long block and primed the engine using the recommended drill to spin the oil pump. At the time I noticed my gage went up to 100psi.

Installed a new gage and same thing, 100psi.

I recently hot tested the engine on a stand and at idle it was around 80psi and at higher idle it went up to 90psi and fluctuated as rpm changed, this also verified with a pressure sending unit so I can rule out the gages.

I called ford and they seem concerned but the engineers have not responded yet.

Iím running the recommended 10w30.

I know I canít be the only one with this problem, any ideas? I believe they use a Mahle pump which is high volume. Iím starting to have anxiety over this because for some reason Iím guessing ford will tell me Iím **** out of luck because they never experienced this before.

Any ideas?

David |

09-25-2023, 11:17 AM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Gilroy,

CA

Cobra Make, Engine: SPF 2291, Whipple Blown & Injected 4V ModMotor

Posts: 2,719

|

|

Not Ranked

Not Ranked

David,

High oil pressure will not hurt you. Low oil pressure will. Whenever you use a high-volume pump, you will get high oil pressure unless you run a softer oil bypass spring.

Using a high-volume pump and reducing the oil bypass spring pressure will reduce the oil pressure and volume to what the low-volume pump provided.

You can only have high volume and low pressure if you substantially increase bearing clearances, which nobody should do.

My engine, which is different than yours, originally used an OEM pump that produced about 20 psi at idle and 45 to 50 psi at elevated engine speeds. Ford later went to a larger pump that would idle at 55 to 60 psi hot and run to 90 psi at higher engine speeds.

Before Ford came out with their Vitamin ‘C’ enhanced pump, I had decided to use a large volume dry sump pressure stage mounted external to the engine in a typical dry sump mounting style. I chose the pump gear width and the drive pulleys to provide 70 psi when hot at idle. I use a large external pressure relief set at 120 psi. My engine’s oil pressure is between 70 and 120 psi, except when the oil is cold, and I start it. No problems whatsoever. I also have a race-only application, Chrysler, that idles a whisker higher at 75/80 psi hot and runs over 150 psi under power.

The only thing you need to be careful about is oil filters. You need to run a racing filter. OEM filters have much lower burst pressures; you will blow them off the engine or burst them during a cold start. You also want to be sure you have a large enough oil pan. A high-volume pump can pump an OEM pan dry before the oil can return. If you intend to run this type of pump, you should run an eight-quart or larger oil pan.

PostScript

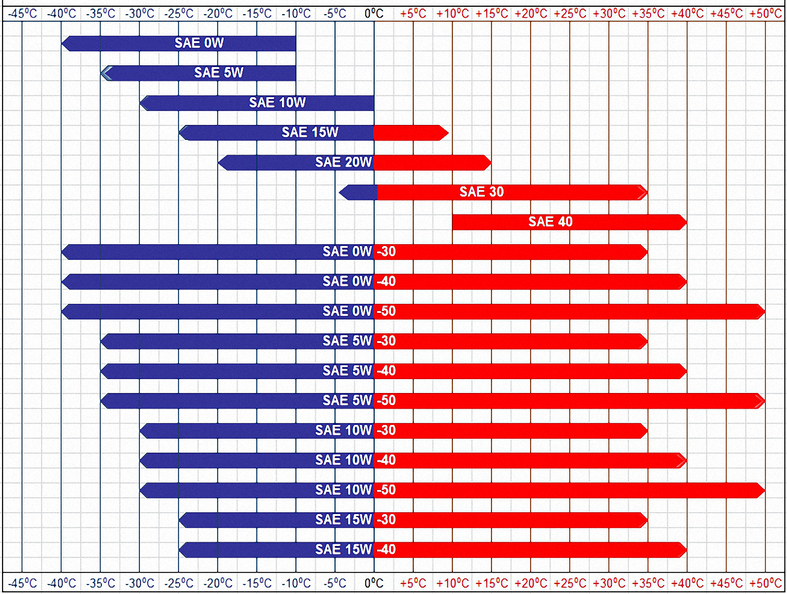

Don’t forget you are observing a cold engine with cold oil pressure right now. If you let the engine come up to operating temps, the oil pressure will go down. I would also give serious consideration to running something better than 10W30. My suggestion would be a 5 or 10W40 or 5 or 10W50, depending on your engine power level and how you drive the car. Here is a chart to help you select your oil viscosity

I believe the above chart is referencing ambient temperatures, not oil temperatures. Nonetheless, it is still a good proxy for viscosity selections. Notice how the chart calls out higher viscosity oils as the temperature scale increases. The higher-viscosity oils perform better at elevated oil operating temperatures.

A 5 or 10 W40 oil would probably be a good choice for your application. The low 5 or 10 rating would mean good lubricity when cold starting, and the 40 or 50 weight rating would mean good protection under load when hot. Don’t shortchange your engine. Parts can be expensive even before you get to the engine repair stage.

__________________

Help them do what they would have done if they had known what they could do.

Help them do what they would have done if they had known what they could do.

Last edited by eschaider; 09-28-2023 at 07:25 PM..

Reason: fixed broken pic link

|

09-25-2023, 02:27 PM

|

|

CC Member

|

|

|

Join Date: Feb 2007

Location: Colorado Springs,

CO

Cobra Make, Engine: Backdraft, supercharged Coyote

Posts: 2,444

|

|

Not Ranked

Not Ranked

A high volume pump should only be used if you have external oiling components: remote filter, cooler, Accusump, etc.

If none of those items are in the mix, then you have a restriction somewhere. Is there good oil flow to every valve stem?

Too much oil pressure is not a good thing. The oil pump is run off the bottom of the distributor, which is run by the gear on the camshaft. It requires a lot of effort to make 100psi. That's wasted energy, and too much strain on the drive mechanism. You have a good chance of shearing the distributor gear roll pin, and wearing out the gear.

__________________

.boB "Iron Man"

NASA Rocky Mountain TTU #42

www.RacingtheExocet.com

BDR #1642 - Supercharged Coyote, 6 speed Auto

|

09-25-2023, 03:09 PM

|

|

CC Member

|

|

|

Join Date: Aug 2000

Location: Pinellas Park,

FL

Cobra Make, Engine: built the molds and body composite construction

Posts: 316

|

|

Not Ranked

Not Ranked

I had a similar event when, I built a 350 Vette engine. Spoke to the people at GM-Corvette Div. I new and they told me to drop the pan remove the pump and take out the spring and ball check and reassemble, rust sometimes stops the ball from moving, it solved the problem. The problem is what happened to me was the pressure was high enough that it blew the oil filter seal and in seconds dumped 2-3 quarts of oil all over. You certainly don't want that to happen the first time you take yours out on the road.

Bill K |

09-25-2023, 07:18 PM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Gilroy,

CA

Cobra Make, Engine: SPF 2291, Whipple Blown & Injected 4V ModMotor

Posts: 2,719

|

|

Not Ranked

Not Ranked

Although a restriction would increase oil pressure, as Bob has suggested, it is improbable but not impossible to have that occur in a brand-new crate engine from Ford. It is far more likely that the spring pressure on the oil pressure relief is set too high or the relief valve is jammed in the oil pump.

If the oil pressure relief is not at fault, the only other possible explanation (other than a stiff spring) is, as Bob has already suggested, a blockage in your internal oil galleys. Bob's point about wasted energy is spot on; however, it is usually indiscernible from a driver's perspective if it only makes a difference between 550 RWHP and 545 RWHP.

If you do have an oil galley blockage somewhere in the lubrication system, it will become apparent in short order. The engine parts that are being starved for lubrication frequently exit the block at high velocity, leaving an unmistakable exit path visible.

The issue about the ability to shear off a roll pin is real. Solid dowel pins are pretty robust and unlikely to break. Roll pins, on the other hand, are more fragile and susceptible to damage. If this is a concern, the easy fix is replacing the roll pin with a solid dowel pin. McMaster-Carr will be your friend.

It is worthwhile remembering that high-volume oil pumps will automatically operate at a higher pressure than their lower-volume kindred unless the additional volume is bled off the high-volume pump output through the oil pressure relief — and then you have a high-volume pump performing as if it were a low volume pump!

This begs the obvious question, 'Why did you bother to use a high-volume pump in the first place?'

My personal opinion is your oil pressure is probably just right for a high-volume pump or a lower-volume pump with a zesty pressure relief spring. Your oil pan may need some increased capacity, depending on how big it currently is.

__________________

Help them do what they would have done if they had known what they could do.

Help them do what they would have done if they had known what they could do.

Last edited by eschaider; 09-25-2023 at 07:27 PM..

Reason: Spelling & Grammar

|

09-25-2023, 08:08 PM

|

|

CC Member

|

|

|

Join Date: Jul 2022

Cobra Make, Engine:

Posts: 91

|

|

Not Ranked

Not Ranked

Thanks for all the info

The Ford long block I bought comes with a high volume pump, nothing I changed.

The engine will be set up with an external oil filter and the supplied filter is a high volume racing filter and the pan holds 9 quarts.

Today I spun the pump with a drill and could get it up around 85 psi.

When using the test stand at idle, warm oil, gage read 80 psi and fluctuated when revving the engine.

Not sure I understand about reducing the bypass spring force, in that case what’s the sense of using a high volume pump?

I find it hard to believe that I have the only long block from Ford that has this problem. Based on my serial number they should be able to see if there were any problems similar to mine.

Guess I will wait and see what the engineers at Ford say about it, after all they have to give me a 24 month warranty, just don’t want to remove the engine from my car if this isn’t right to begin with.

Thanks again for the reply’s.

David

Last edited by Davidless; 09-25-2023 at 08:11 PM..

|

09-25-2023, 10:21 PM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Gilroy,

CA

Cobra Make, Engine: SPF 2291, Whipple Blown & Injected 4V ModMotor

Posts: 2,719

|

|

Not Ranked

Not Ranked

From post #5

Quote:

Originally Posted by eschaider

... My personal opinion is your oil pressure is probably just right for a high-volume pump or a lower-volume pump with a zesty pressure relief spring. Your oil pan may need some increased capacity, depending on how big it currently is.

|

__________________

Help them do what they would have done if they had known what they could do.

Help them do what they would have done if they had known what they could do.

|

09-26-2023, 09:59 AM

|

|

CC Member

|

|

|

Join Date: Feb 2007

Location: Colorado Springs,

CO

Cobra Make, Engine: Backdraft, supercharged Coyote

Posts: 2,444

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Davidless

Thanks for all the info

Not sure I understand about reducing the bypass spring force, in that case whatís the sense of using a high volume pump?

David

|

Do not equate pressure with volume.

__________________

.boB "Iron Man"

NASA Rocky Mountain TTU #42

www.RacingtheExocet.com

BDR #1642 - Supercharged Coyote, 6 speed Auto

|

09-26-2023, 10:48 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,000

|

|

Not Ranked

Not Ranked

There are times when you want a high volume pump. In contrast to your small block, my stroked flat tappet FE has .003 main clearances and .0028 rod clearances. It also has a remote filter and an oil cooler. It runs 15w40 oil and my hot idle pressure is 15psi, sometimes less. This is when idling at 650 and my oil pressure comes up instantly with revs and generally will be in the mid 40's at 2000 RPM when really hot. The lifter galleries are plugged (solid cam) and I have .060 restrictors up top in the heads. And I run a Melling high volume pump.

|

09-26-2023, 10:57 AM

|

|

CC Member

|

|

|

Join Date: Feb 2014

Location: White City,

SK

Cobra Make, Engine: West Coast, 460 CID

Posts: 2,908

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Davidless

Hi All

Iím at a pickle with my new ford racing 427 sb crate engine.

I finished dressing the long block and primed the engine using the recommended drill to spin the oil pump. At the time I noticed my gage went up to 100psi.

Installed a new gage and same thing, 100psi.

I recently hot tested the engine on a stand and at idle it was around 80psi and at higher idle it went up to 90psi and fluctuated as rpm changed, this also verified with a pressure sending unit so I can rule out the gages.

I called ford and they seem concerned but the engineers have not responded yet.

Iím running the recommended 10w30.

I know I canít be the only one with this problem, any ideas? I believe they use a Mahle pump which is high volume. Iím starting to have anxiety over this because for some reason Iím guessing ford will tell me Iím **** out of luck because they never experienced this before.

Any ideas?

David

|

When you say "hot tested" do you mean the engine was run long and hard enough to get the oil to operating temperature (>200 deg F)? If not, then do so and let us know what the oil pressure readings are at idle and 3,000 RPM with hot oil.

IMO, changing relief valve springs or oil viscosity before you do the above is wasting time and money and possibly counter-productive.

__________________

Brian

|

09-26-2023, 01:56 PM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Gilroy,

CA

Cobra Make, Engine: SPF 2291, Whipple Blown & Injected 4V ModMotor

Posts: 2,719

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by bobcowan

Do not equate pressure with volume.

|

Pressure and flow rate (volume) are linked at the hip, although they do not have a first-order relationship. The relationship between pressure and flow is a second-order relationship.

Flow increases as the square of pressure. To double the flow through an orifice, you will need to raise the pressure of the fluid pre-orifice by a factor of four (2 squared).

It is not just simplistic to say they are not related, it is wrong. They are linked at the hip.

__________________

Help them do what they would have done if they had known what they could do.

Help them do what they would have done if they had known what they could do.

|

09-26-2023, 03:10 PM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Gilroy,

CA

Cobra Make, Engine: SPF 2291, Whipple Blown & Injected 4V ModMotor

Posts: 2,719

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by cycleguy55

... IMO, changing relief valve springs or oil viscosity before you do the above is wasting time and money and possibly counter-productive.

|

+1 on what Brian (cycleguy55) said!

You are suffering from internet fictional information overload, David. There is nothing wrong with your engine. It will perform well for you for a long time with normal care. The oil pressure will do no damage to the engine.

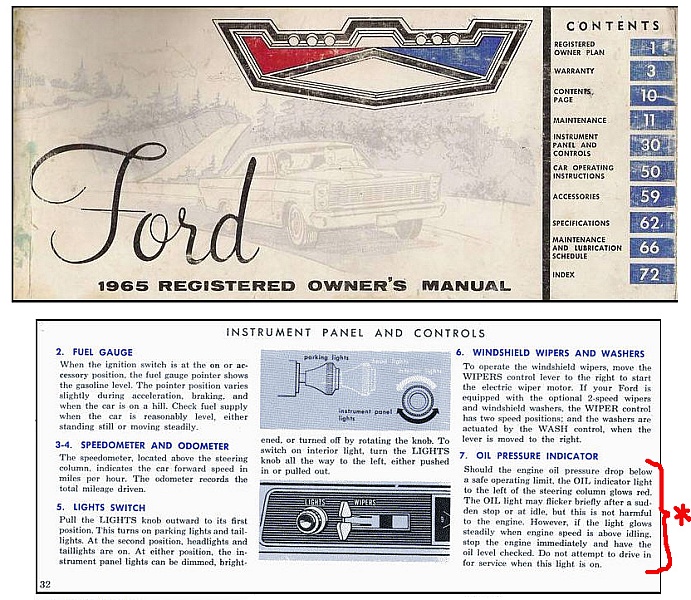

The one tender area that Bob identified, the potential for a distributer drive gear roll pin failure, is real and should not be ignored. If a roll pin has been used, it should be replaced with a traditional dowel pin. The dowel pin strength is vastly superior to the roll pin.

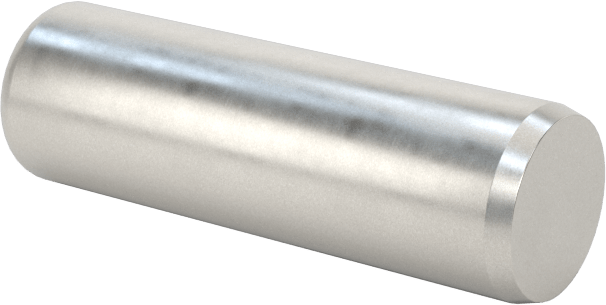

There are differing types of roll pins with differing strengths. This is a pic of a simple slotted tubular roll pin;

It is on the low end of the strength scale and the easiest of all the choices to fail. This pin in a 5/32 diameter (0.156") has a breaking strength of just over 2000 lbs. Its durability can be somewhat improved by using spring steel. The underlying problem is insufficient metal to provide strength. It should not be used in moderate to high torque applications.

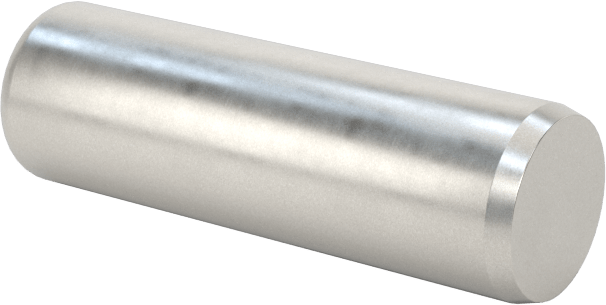

The next step up the ladder is the rolled roll pin, no pun intended. This pin is essentially a spiral version of the slotted design. It looks like this;

The rolled steel roll pin in the same 5/32" diameter has a breaking strength of 2200 lbs. Not a shrinking violet but there is better available. If you get the hardened steel versions, this pin will have a breaking strength of 2700 lbs. It's better, but there is still one more alternative. This is what it looks like:

A solid steel dowel pin, in a 5/32 diameter, has a breaking strength of 4100 lbs. It is highly improbable that you could damage that pin when using it to anchor the drive gear on the distributor. Of course, you could go up 1/32" to a 3/16" diameter pin. The breaking strength jumps by almost 50% to 5,900 lbs. This one fits into the virtually unbreakable category for your type of service.

The chances are 50/50 that Ford used a solid steel pin. It is more likely they used a rolled roll pin. Easy peasy, lemon squeezey, as the saying goes. Simply push out the old, push in the new, and don't worry, be happy.

Your oil pressure is not out of line. Could it be lower? Absolutely! Switch to a softer pressure relief spring? That is the oil pressure equivalent of discovering your car can smoke the tires with very little encouragement from the driver's right foot.

To fix the tire smoking problem, you have three choices;

- Put on sticky racing tires,

- Learn how to leave without smoking the tires,

- Disconnect two plug wires to kill off some power,

The one we all know is wrong is disconnecting two spark plug wires. In your case, you don't need to put the equivalent of sticky racing tires on the car or even learn how to leave w/o smoking the tires. All you have to do is put in a solid dowel pin (to ease your fears), drive your car and enjoy it!

__________________

Help them do what they would have done if they had known what they could do.

Help them do what they would have done if they had known what they could do.

Last edited by eschaider; 09-26-2023 at 03:20 PM..

Reason: Fixed Broken Pic Link

|

09-27-2023, 05:25 AM

|

|

CC Member

|

|

|

Join Date: Jul 2022

Cobra Make, Engine:

Posts: 91

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by cycleguy55

When you say "hot tested" do you mean the engine was run long and hard enough to get the oil to operating temperature (>200 deg F)? If not, then do so and let us know what the oil pressure readings are at idle and 3,000 RPM with hot oil.

IMO, changing relief valve springs or oil viscosity before you do the above is wasting time and money and possibly counter-productive.

|

Yes I agree, a high volume oil pump will create more pressure because the restrictions havenít changed. Everyone Iíve talked too says this pressure is typical of a high volume pump. When the oil heats up, the pressures should drop 20 psi. Thatís is what some life long engine builders have said. |

09-27-2023, 05:36 AM

|

|

CC Member

|

|

|

Join Date: Jul 2022

Cobra Make, Engine:

Posts: 91

|

|

Not Ranked

Not Ranked

I understand what you guys mean about a solid roll pin, but imo since I purchased a performance distributor by Prestige, itís crazy to believe they would have designed this thing with an inadequate roll pin to save a few cents.

Am I missing something?

I guess itís easy enough to check

|

09-27-2023, 05:38 AM

|

|

CC Member

|

|

|

Join Date: Jul 2022

Cobra Make, Engine:

Posts: 91

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by eschaider

+1 on what Brian (cycleguy55) said!

You are suffering from internet fictional information overload, David. There is nothing wrong with your engine. It will perform well for you for a long time with normal care. The oil pressure will do no damage to the engine.

The one tender area that Bob identified, the potential for a distributer drive gear roll pin failure, is real and should not be ignored. If a roll pin has been used, it should be replaced with a traditional dowel pin. The dowel pin strength is vastly superior to the roll pin.

There are differing types of roll pins with differing strengths. This is a pic of a simple slotted tubular roll pin;

It is on the low end of the strength scale and the easiest of all the choices to fail. This pin in a 5/32 diameter (0.156") has a breaking strength of just over 2000 lbs. Its durability can be somewhat improved by using spring steel. The underlying problem is insufficient metal to provide strength. It should not be used in moderate to high torque applications.

The next step up the ladder is the rolled roll pin, no pun intended. This pin is essentially a spiral version of the slotted design. It looks like this;

The rolled steel roll pin in the same 5/32" diameter has a breaking strength of 2200 lbs. Not a shrinking violet but there is better available. If you get the hardened steel versions, this pin will have a breaking strength of 2700 lbs. It's better, but there is still one more alternative. This is what it looks like:

A solid steel dowel pin, in a 5/32 diameter, has a breaking strength of 4100 lbs. It is highly improbable that you could damage that pin when using it to anchor the drive gear on the distributor. Of course, you could go up 1/32" to a 3/16" diameter pin. The breaking strength jumps by almost 50% to 5,900 lbs. This one fits into the virtually unbreakable category for your type of service.

The chances are 50/50 that Ford used a solid steel pin. It is more likely they used a rolled roll pin. Easy peasy, lemon squeezey, as the saying goes. Simply push out the old, push in the new, and don't worry, be happy.

Your oil pressure is not out of line. Could it be lower? Absolutely! Switch to a softer pressure relief spring? That is the oil pressure equivalent of discovering your car can smoke the tires with very little encouragement from the driver's right foot.

To fix the tire smoking problem, you have three choices;

- Put on sticky racing tires,

- Learn how to leave without smoking the tires,

- Disconnect two plug wires to kill off some power,

The one we all know is wrong is disconnecting two spark plug wires. In your case, you don't need to put the equivalent of sticky racing tires on the car or even learn how to leave w/o smoking the tires. All you have to do is put in a solid dowel pin (to ease your fears), drive your car and enjoy it! |

This Ford performance long block doesnít come with a dist, you choose your own.

See my bottom comment

Thanks

|

09-27-2023, 11:35 AM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Gilroy,

CA

Cobra Make, Engine: SPF 2291, Whipple Blown & Injected 4V ModMotor

Posts: 2,719

|

|

Not Ranked

Not Ranked

It doesn't matter who supplied the distributor. The issue is not the supplier, it is the parts used in the manufacture of the finished product. Roll pins are cheap and easy to install, and that is what makes them attractive.

Your issue as the owner of the equipment now becomes, what do you intend to do, if anything at all?

__________________

Help them do what they would have done if they had known what they could do.

Help them do what they would have done if they had known what they could do.

|

09-27-2023, 11:39 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,000

|

|

Not Ranked

Not Ranked

Maybe just trade your small block in for an FE and then you could idle at 6 psi like most of the FEs used to do.

|

09-27-2023, 01:15 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Mar 2000

Location: St. Augustine,

FL

Cobra Make, Engine: E-M / Power Performance / 521 stroker / Holley HP EFI

Posts: 1,926

|

|

Not Ranked

Not Ranked

Interesting thread...

As far as pinning the distributor to the gear there at least four levels available:

1) the stock pin which can fail (the failure is almost certainly pure shear)

2) double pinning can be used; two pins are used one above the other (but not too close) and at 90 degrees from each other. Those who've tried it claim it works fine.

3) a hardened roll pin in the standard OD

4) a larger OD hardened roll pin; the diameter increase can be small so as not to weaken the shaft; a small increase in diameter will give a significant increase in shear strength. I have read about one setup where a 5/32" roll pin is used with a 3/32" one nested inside the larger one. The "splits" were 180 degrees apart. It replaced a 1/8" roll pin.

What flavor should be used? Slightly subjective maybe ;-)

Tom

__________________

Wells's law of engine size: If it matters what gear you're in, the engine's too small!

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 05:20 PM.

Links monetized by VigLink

|