Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

|

1 |

| 2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 9 |

10 |

11 |

12 |

13 |

14 |

15 |

| 16 |

17 |

18 |

19 |

20 |

21 |

22 |

| 23 |

24 |

25 |

26 |

27 |

28 |

29 |

| 30 |

31 |

|

|

|

|

|

|

CC Advertisers

CC Advertisers

|

|

1Likes 1Likes

-

1

Post By Wbulk

1

Post By Wbulk

02-25-2015, 05:07 PM

|

|

CC Member

|

|

|

Join Date: May 2009

Location: American Fork,

Ut

Cobra Make, Engine: 66 Cobra

Posts: 930

|

|

Not Ranked

Not Ranked

Rocker Geometry

Rocker Geometry

I was wondering if anyone on the forum had tried the Mid-Lift rocker geometry method? It was first patented by Jim Miller in 1982. This YouTube Video is a variation of that method but just looks at the valve side at mid-lift. This is not the centering the rocker roller on the valve stem method.

[ame="https://www.youtube.com/watch?v=o5is9BsH5OU"]https://www.youtube.com/watch?v=o5is9BsH5OU[/ame]

I am building a spare engine and am pondering taking some detailed measurements to determine if the ratio and lift are more accurate using this method.

__________________

Wayne

"Everything is alive. If you get angry at a vehicle or the trans, it won't fix until you apologize and say you are sorry." "The vehicle always knows what it is doing and what the cause of it's bad feeling is. If you ask it humbly what the problem is, it will tell you. Then you and it will both be happy."

Gil Younger

|

02-25-2015, 11:42 PM

|

|

CC Member

|

|

|

Join Date: May 2008

Location: Brisbane,

QLD

Cobra Make, Engine:

Posts: 2,797

|

|

Not Ranked

Not Ranked

Finally somebody has posted "the right way".

Have done it that way many times, my own logic.

Logic says 90 degrees at half lift is correct. It allows the smallest width contact patch across the valve stem from closed to max lift and back to closed.

The rocker tip swings in an arc. If the tip travels from 2 o'clock through 3 o'clock at mid lift (90 degrees to the valve stem) to 4 o'clock at max lift, the travel ACROSS the valve stem is a shorter distance. The shorter the distance travelled, the less loading on the valve stem and guide which prolongs component life.

__________________

Gary

Gold Certified Holden Technician

Last edited by Gaz64; 02-25-2015 at 11:54 PM..

|

02-26-2015, 03:04 AM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

There are wives tales that get passed around from forum to forum and accepted as gospel....

One of which is that the rocker arm pattern has to be perfectly centered on the stem.

If you have some checking springs, an adjustable pushrod, and a dial indicator/mag base, go through .025" increments and watch what it does to the net lift that you get a the retainer. You'll be surprised.

|

02-26-2015, 06:18 AM

|

|

CC Member

|

|

|

Join Date: May 2009

Location: American Fork,

Ut

Cobra Make, Engine: 66 Cobra

Posts: 930

|

|

Not Ranked

Not Ranked

I knew you guys would get this. Think of how much money the cam companies are making selling push rods to guys that think the stem pattern is the most important. I called the big cam company tech support to determine what heads and rockers they use to design and test their cams on a 5.0 roller. He didn't know and could not discuss the issue. I found out later they don't even make their own rockers, so they have no idea of the issues. There are a lot of issues with rocker geometry that are never discussed. How the rocker is made is critical to that ever changing arch of the rocker as it moves through it's travel.

Consider, a cam that is designed with one set of heads and rockers vs. another head and different rockers. Then you add in how the geometry of the rocker is set up. The result on the engine performance could be significantly different. Explaining why one guy hates a cam and another loves it; maybe it's not the cam.

Interesting, when I called Scorpion they knew exactly what heads are used to test their rockers. The relationship of the valve tip, to the pivot point, to the push rod height all effect the geometry. We put so much importance on making sure the cam is degreed in to spec., but little to none on the rest of the items to insure the opening of the valve is actually tuned.

This is a tough subject. I am going to do some testing. I am thinking put the degree wheel back on and test stock vs. mid-lift method taking valve height readings every 10 degrees of crank rotation during the cycle of the valve. The test method is important, so if you have an opinion on how it should be set up lets hear it. On the other hand if you have information on tech articles where this has been done, point me in that direction.

Another interesting video on push rod length effecting rocker ratio, which all ties in.

[ame="https://www.youtube.com/watch?v=RjaosX63DkM"]https://www.youtube.com/watch?v=RjaosX63DkM[/ame]

__________________

Wayne

"Everything is alive. If you get angry at a vehicle or the trans, it won't fix until you apologize and say you are sorry." "The vehicle always knows what it is doing and what the cause of it's bad feeling is. If you ask it humbly what the problem is, it will tell you. Then you and it will both be happy."

Gil Younger

Last edited by Wbulk; 02-26-2015 at 07:54 AM..

Reason: spelling

|

02-26-2015, 01:19 PM

|

|

CC Member

|

|

|

Join Date: Jul 2009

Location: Westerly,

RI

Cobra Make, Engine: Fordstroker 408w custom solid roller-Craft ported Brodix 17*heads-CFM ported Vic Jr. intake-1 3/4 primaries- 575hp-TKO-600RR Liberty upgrade- -Moser 8.8 trutrac-McLeod Street Extreme--QA-1-Wilwood brakes, Classic Chambered 3" Cobrapacks, Avon's

Posts: 645

|

|

Not Ranked

Not Ranked

Been through this and I contacted Paul Kane who knows Jim Miller very well. After a long discussion I purchased the Miller rockers. I tried Crower Back set 1.6 and 1.65, Comp Cams, Scorpion, and the Miller rockers gave me perfect 90 angles on both sides of the rocker. Everyone keeps looking at the valve side for mid lift but tru mid lift has to be looked at from both sides of the rocker arm. No rocker arm can achieve this, and the ones I named cant for sure. I just had a long post on yellow bullet in the valvetrain section. I got a couple suggestions but no one really wanted to get into it. I use to think that a narrow witness mark was the go to answer, but it's only part of it and really the result. I was able to achieve rocker arm roller tip location, pattern and good rushrod angle, and finally after a few years of battling this compromise as everyone calls it, I figured it out. So now I have my Morel Ultra-Pro lifters, Manton 8.00" series 4 push rods Miller rocker arms and some valve springs with 170lbs. on the seat and 450lbs on the nose and yes with Mike Jones hydraulic roller cam. Can't wait for the Hot Rod season !!!

__________________

Lou

|

02-26-2015, 01:37 PM

|

|

CC Member

|

|

|

Join Date: Jul 2009

Location: Westerly,

RI

Cobra Make, Engine: Fordstroker 408w custom solid roller-Craft ported Brodix 17*heads-CFM ported Vic Jr. intake-1 3/4 primaries- 575hp-TKO-600RR Liberty upgrade- -Moser 8.8 trutrac-McLeod Street Extreme--QA-1-Wilwood brakes, Classic Chambered 3" Cobrapacks, Avon's

Posts: 645

|

|

Not Ranked

Not Ranked

The problem is there are so many variables that come into play. Head manufactures have different valve angles, stud locations, stud angles, valve tip heights are changing, and no standards in the industry. It really has to be looked at so you can minimize guide wear, stud flex, correct lobe information getting transferred to the valve which effects lift and area under the curve. It's overlooked too often. I was compromising between perfect geometry at the valve tip (90*) with a small pattern and the rocker tip location (which was always too far outboard on the vale tip). I could never get it all correct and everyone said you have to compromise, but it bothered me and I looked for answers. I never thought of the the importance of getting the pushrod side correct until Paul explained it all to me.

__________________

Lou

|

02-26-2015, 03:47 PM

|

|

CC Member

|

|

|

Join Date: May 2009

Location: American Fork,

Ut

Cobra Make, Engine: 66 Cobra

Posts: 930

|

|

Not Ranked

Not Ranked

You got it Lou!

I tried the mid-lift at the stem side and ended up the same as you, roller on the outside, but with a great narrow pattern. I have read Millers articles and he really get's into the pushrod side, but that is a lot harder to measure. Interesting that cam companies don't want to take the issue on.

So, please explain, if you have the stem side correct at mid-lift, is that not the better compromise. Wouldn't it be far better than just doing it the old way and forgetting about it.

__________________

Wayne

"Everything is alive. If you get angry at a vehicle or the trans, it won't fix until you apologize and say you are sorry." "The vehicle always knows what it is doing and what the cause of it's bad feeling is. If you ask it humbly what the problem is, it will tell you. Then you and it will both be happy."

Gil Younger

|

02-26-2015, 04:23 PM

|

|

CC Member

|

|

|

Join Date: Jul 2009

Location: Westerly,

RI

Cobra Make, Engine: Fordstroker 408w custom solid roller-Craft ported Brodix 17*heads-CFM ported Vic Jr. intake-1 3/4 primaries- 575hp-TKO-600RR Liberty upgrade- -Moser 8.8 trutrac-McLeod Street Extreme--QA-1-Wilwood brakes, Classic Chambered 3" Cobrapacks, Avon's

Posts: 645

|

|

Not Ranked

Not Ranked

Getting the valve stem axis 90* or perpendicular to the center lines of the trunnion and roller tip centerline at half your net valve lift is partially correct. Because rocker arms are not geometrically correct the pushrod cup is not where it is suppose to be. Usually it is set to high in the rocker body, and when you get the valve side correct, the pushrod tip is slightly over arcs. Both side move in arcs and you want balance on both sides. Since you really cant get the balance you'll have to compromise. You will be better off getting a shorter pushrod than what wold be geometrically correct for the valve side so the push rod will not over arc ( losing cam information to the rocker arm). This will bring your pattern inboard a little and give you somewhat a better balance, hence the compromise. Rocker arm manufactures don't get it right for some reason. You can get surprisingly close to the outboard side of the valve tip without compromising your valvetrain. Smokey Yunick says .020 but that is too close for me. Lash caps my help to widen the tip but now you add height.

__________________

Lou

|

02-26-2015, 04:35 PM

|

|

CC Member

|

|

|

Join Date: May 2009

Location: American Fork,

Ut

Cobra Make, Engine: 66 Cobra

Posts: 930

|

|

Not Ranked

Not Ranked

Good information Lou. I'm going to take some measurements and see where this goes.

Thanks.

Added: One thing I remember Miller said was to take a torque wrench on the crank bolt and measure the turning pounds before and after you get the geometry right. The engine will be a lot easier to turn after words.

__________________

Wayne

"Everything is alive. If you get angry at a vehicle or the trans, it won't fix until you apologize and say you are sorry." "The vehicle always knows what it is doing and what the cause of it's bad feeling is. If you ask it humbly what the problem is, it will tell you. Then you and it will both be happy."

Gil Younger

Last edited by Wbulk; 02-26-2015 at 04:42 PM..

Reason: Added

|

02-26-2015, 05:16 PM

|

|

CC Member

|

|

|

Join Date: Jul 2009

Location: Westerly,

RI

Cobra Make, Engine: Fordstroker 408w custom solid roller-Craft ported Brodix 17*heads-CFM ported Vic Jr. intake-1 3/4 primaries- 575hp-TKO-600RR Liberty upgrade- -Moser 8.8 trutrac-McLeod Street Extreme--QA-1-Wilwood brakes, Classic Chambered 3" Cobrapacks, Avon's

Posts: 645

|

|

Not Ranked

Not Ranked

Right, with less pushrod angle moving into the arc at 90* its almost straight motion and no wasted motion. The roller tip moving straight down on the valve stem, there is minimal sliding and guide wear. There is less forces on the stud minimizing flex. It all makes sense when you see it in motion.

Good Luck Wayne.

__________________

Lou

|

03-03-2015, 11:23 AM

|

|

CC Member

|

|

|

Join Date: May 2009

Location: American Fork,

Ut

Cobra Make, Engine: 66 Cobra

Posts: 930

|

|

Not Ranked

Not Ranked

Testing Rockers

Testing Rockers

To continue this project I read everything I could on the subject, including: Jim Miller's articles, his patent, some engineering articles that mention Milller's mid-lift method and hours of reading various forums. I also called two major companies that sell rockers. To be honest I was disappointed in all of it. I was hoping to find something with “some testing and results.” I found nothing but stated conclusions based on beliefs and not supported by testing and results. It may be somewhere but I couldn't find it.

I, like many others, have been building engines on and off since the mid-sixties, mostly as a hobby, but at many times to make extra money. I had four years of formal auto shop training and lived for it but I never got into the geometry of the rocker arms other than switching out some 1.5s for 1.6s. I have been degreeing cams in for about twenty five plus years but just never thought that all that work on cam design could be negated by a bad rocker design. Who would have thought a 1.6 rocker may not produce close to 1.6 of cam lift?

Lacking some testing results other than the second video above I decided to do some testing of my own. I wanted to see what was really happening at the valve. Now I know why the cam companies call it “theoretical lift.” After talking with Scorpion, I realized there had to be a method to get an idea of what was happening without buying tons of rockers so I decided to start with three rockers a lot of us have; a stock pedestal rocker, a Comp Cams Magnum and a stock old style cast steel sixties/seventies rocker; all 1.6 ratio.

TESTING METHOD

I tested the rockers on a mild built spare roller 5.0 engine I just finished building. It has a Comp Extreme Energy cam #35-320-8 with Ford Racing Roller lifters. The heads are fully ported cast iron E7s with Trick Flow springs and retainers. The cam had been degreed in and was overall pretty good. The lift was checked at the cam and was within a couple thousands.

An old lifter was taken apart, the valve and spring removed. The lower piston turned upside down and shims added so it was solid but approx. .035 down from the clip to simulate actual pre-load running conditions. Since this has a lot to do with pushrod length this is critical to do a running set-up, not just adding the pre-load measurement later. This cannot be done accurately with a stock pumped up lifter as they will bleed down in the middle of testing.

The degree wheel was set up and TDC'd on the crank. The degree wheel was marked at .006 start of intake lift and every 20 degrees of crank rotation, the lobe center and ½ lift positions were also marked and the .006 valve closed point. An adjustable pushrod was used. A 1” dial indicator was set-up on the valve retainer, inline with the valve movement.

In doing research I found that there are actually two variations of the mid-lift method. The one in the first video that is based on the theoretical gross valve lift and Millers method, based on the net cam lift measured from the stem side roller center to the fulcrum center less ½ net lift. Meaning the center of the fulcrum less ½ the net lift measured at 90 degrees to the valve stem. In this case, the center point of the fulcrum needed to be .160 based on .320 cam lift, below the center of the valve stem side roller tip, or if there is no roller, the shoe or sled surface of the rocker to the center fulcrum roller or center pivot point. The Miller method is more difficult to measure but there is no tightening the rocker bolt and counting the turns in this process. You use the adjustable pushrod to raise or lower to the proper rocker height and then measure the pushrod length.

I completed seven tests measuring and recording at each 20 degree crank rotation plus the ½ lift and actual gross lift points. I tested all three rockers with a stock pushrod. I tested the Comp Cams and the old cast steel rocker using the ½ gross lift method. I tested those two again using the ½ lift net method.

One thing I realized during the testing is that the gross lift is an in-the-ballpark test because the gross valve may not be correct from the start. So, starting from that “theoretical gross valve lift” figure is highly suspect.

The results will have to be in another post as I am trying to figure a good method to present them. Let me just say I had no idea and was shocked.

__________________

Wayne

"Everything is alive. If you get angry at a vehicle or the trans, it won't fix until you apologize and say you are sorry." "The vehicle always knows what it is doing and what the cause of it's bad feeling is. If you ask it humbly what the problem is, it will tell you. Then you and it will both be happy."

Gil Younger

Last edited by Wbulk; 03-03-2015 at 08:16 PM..

Reason: Picture added

|

03-03-2015, 07:26 PM

|

|

CC Member

|

|

|

Join Date: May 2009

Location: American Fork,

Ut

Cobra Make, Engine: 66 Cobra

Posts: 930

|

|

Not Ranked

Not Ranked

Rocker Testing Results

Rocker Testing Results

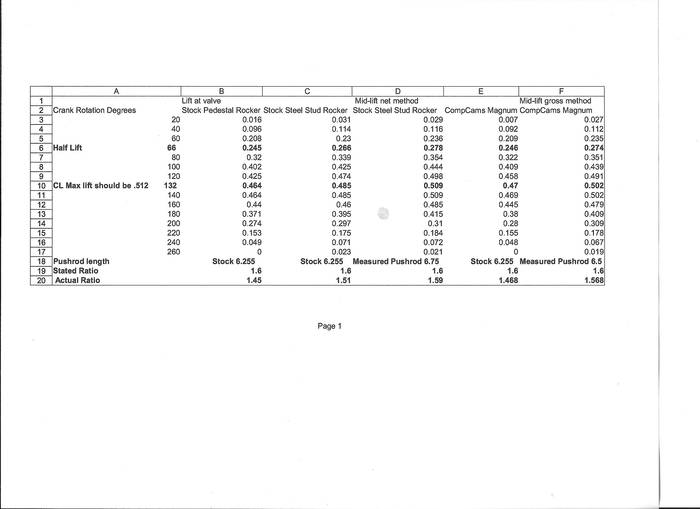

The results of the test are in the table below. Notice under B, C, and E these were all tested with the stock pushrod in stock form. From these the old style cast stock rocker was best with an actual ratio of 1.51 followed by the Comp Cams Magnum with 1.468 and then the stamped steel pedestal rocker at only 1.45 ratio.

Under D and F columns these results were by using the mid-lift net method and the mid-lift gross method, measuring the correct pushrod length and adjusting the adjustable pushrod to that length, running it through the test sequence and recording the lift measurements. It was amazing to me how both these lifts came up considerably over the whole 260 degree lift range over the stock figures. Also interesting was the old stock cast steel rocker came out the best with a total lift of .509 and an actual ratio of 1.59. This was attained by using the net mid-lift method. I used net method on the stock cast steel rocker (D column) because with the gross method the rocker retainer was hitting the top of the retainer.

I think the lesson learned through this testing process was a demonstrated need to measure your rockers to determine how close the ratios are compared to what they are supposed to be, and that the mid-lift method does work for raising the lift over the entire range.

Now consider if you changed heads, have roller rockers and new roller lifters how far things could really be off. If I was buying an expensive engine I would want to know the actual test in the table on what I was getting.

Added: The results would be far better represented in a line graph but this is the best I could do. If anyone knows how to do graphs really well that would be great if this data could be converted over.

__________________

Wayne

"Everything is alive. If you get angry at a vehicle or the trans, it won't fix until you apologize and say you are sorry." "The vehicle always knows what it is doing and what the cause of it's bad feeling is. If you ask it humbly what the problem is, it will tell you. Then you and it will both be happy."

Gil Younger

Last edited by Wbulk; 03-04-2015 at 07:13 AM..

Reason: fixed spelling, added comment

|

03-04-2015, 02:24 AM

|

|

CC Member

|

|

|

Join Date: Jul 2009

Location: Westerly,

RI

Cobra Make, Engine: Fordstroker 408w custom solid roller-Craft ported Brodix 17*heads-CFM ported Vic Jr. intake-1 3/4 primaries- 575hp-TKO-600RR Liberty upgrade- -Moser 8.8 trutrac-McLeod Street Extreme--QA-1-Wilwood brakes, Classic Chambered 3" Cobrapacks, Avon's

Posts: 645

|

|

Not Ranked

Not Ranked

Very nice work Wayne. Now can you imagine the difference in stress, movement and location if you altered the pushrod side of the rocker arm to being geometrically accurate like the Miller arms. Also the Miller rocker Arms have a machined surface on the top that can be used to measure angles on both sides of the rocker arm to get the 90* correct. You mentioned that you had difficulty measuring the pushrod side, well this makes it easy. Between your work on lift and mine on location and angle we both came to the same conclusion, True Mid Lift and perpendicularity on both sides of the rocker arm flat out works and makes sense.

That's also T-7 aluminum

Lou

__________________

Lou

|

03-04-2015, 06:23 AM

|

|

CC Member

|

|

|

Join Date: May 2009

Location: American Fork,

Ut

Cobra Make, Engine: 66 Cobra

Posts: 930

|

|

Not Ranked

Not Ranked

Lou, you are right on. I didn't even get into the pushrod side of geometry yet. I can easily see how the geometry of your Miller rockers is far better. The pivot point on the fulcrum is higher. The gross method from the valve side in the first video is an improvement but it can never be perfect unless the rocker is designed correct. The starting point presumption that the gross valve lift is correct is really unknown at that point.

Thanks Lou.

__________________

Wayne

"Everything is alive. If you get angry at a vehicle or the trans, it won't fix until you apologize and say you are sorry." "The vehicle always knows what it is doing and what the cause of it's bad feeling is. If you ask it humbly what the problem is, it will tell you. Then you and it will both be happy."

Gil Younger

|

03-05-2015, 01:07 AM

|

|

CC Member

|

|

|

Join Date: Mar 2015

Location: San Francisco Bay Area,

CA

Cobra Make, Engine:

Posts: 20

|

|

Not Ranked

Not Ranked

This thread was brought to my attention in hopes that I may be able to shed some light or offer some insight as to what the Mid-Lift standard is, and how it differs from geometry theories which use an alternate approach to setting up an overhead valve pushrod valve train.

My name is Paul and I own a boutique parts manufacturing business for the 385 Series Ford (429 460), High Flow Dynamics (HFD). HFD is not a parts house like Summit Racing or Jegs; for the most part we sell only the parts that we design and manufacture in-house. One of the few exceptions to that rule is Miller Rockers, and that came to be because I saw the advantages of the Mid-Lift geometry standard and, appreciating its significance, I wanted to make such components available to those who use our in-house products.

Many of the posts in this thread are already filled with numerous ideas, approaches to valve train setup, and even some side-by-side evaluation and data gathering (which really still needs to be better mined and graphed so as to show how greatly geometry efficiency really does matter). My sifting thought each post to give my thoughts in a single sitting would be extremely time consuming, let alone leave an impression of a know-it-all. As a newbie I don't want to come across that way; I would only like to clarify exactly what the Mid-Lift standard is. With that in mind, I think I'd like to start by offering some corrections on the terminology being thrown around, and also touch lightly on some of the other geometry theories and what they don't offer relative to the Mid-Lift standard.

In the first video above that uses the Crane Gold rocker arm on the BBC, the method being explained is known as the "minimal sweep" theory. It is not the Mid-Lift standard, nor does it address all aspects of valve train geometry. The primary focus with the "minimal sweep" theory is to set the trunnion-to-roller axis perpendicular to the valve stem at 50% valve lift. While this theory is well-intentioned, it does not address all aspects of valve train geometry, nor does it necessarily establish the most efficient setup (in fact the final results violate certain aspects of a rocker arm's potential efficiency). It is a very elementary approach that is easy for hot rodders or shade-tree mechanics to default to when needing some consistent valve train setup which ought to offer a reasonable amount of stability in the majority of running engines. But that isn't to say that a more efficient geometric valve train setup that transfers a greater amount of cam information to the valve isn't possible, and in fact better results can be had that have less valve train loading and frictional losses, less wasted motion, less potential for unruly harmonics, more area under the curve, even with the exact same components on the same engine. To me, the most unfortunate situation with the minimal sweep theory is that because it is so stripped down, basic, incomplete (from an overhead valve pushrod V8 valve train geometry stand point) and thereby easy to understand, it leads people to mistakenly believe that they now have a good understanding of valve train geometry when other important aspects haven't even been taken into consideration. Add the internet into the equation (for high visibility) and suddenly everyone who follows the minimal sweep theory think they have a thorough understanding of valve train geometry when in fact they've caught only a glimpse of it.

In the second video above that uses stamped steel shoe-type rockers on an SBC, the modifications being done to the valve train are wildly in opposition to the rules of engineering efficiency. The pushrod lengths are being juggled in the SBC in an attempt to impose more lift at the valve even if it is at the expense of optimized valve train geometry. Now there may be exceptions where this is necessary, such as participating in a racing class that incorporates class restrictions such as a spec rocker arm rule and spec camshaft rule (ie, everyone has to use the same rockers and cam profile); in that case one may opt to sacrifice good geometry so as to gain power advantage via the greater lift at the valve. In other words, the change in pushrod length is forcing the rocker arm to serve as a second dynamic to the camshaft profile (ie, tricking the engine into thinking it has a bigger cam). Sometimes the power gains may outweigh the loss in efficiency, sometimes it's not worth it in the long haul. But if the "spec" engine lasts the length of the race and/or gains the win then so be it. If you do not have such class restrictions but still want more lift at the valve (ie, more power), then keep your geometry as efficient and as optimized as possible and instead make your change at the cam.

When it comes to the Mid-Lift standard, there are two types of geometry that are referenced in the Mid-Lift standard: the first is the design geometry, which is the rocker arm design engineered for the valve train with which it will be utilized. The other is the installed geometry, which references the installation and optimization of a rocker arm into the valve train (the "geometry" of which most people are familiar). In order to establish Mid-Lift standard you need both types of geometry for the intended application. In other words, if you don't have a rocker arm that has proper design geometry for a given engine application, the valve train's installed geometry optimization suffers. Establishing the Mid-Lift standard in an engine's valve train doesn't necessarily require a Miller rocker, it requires a rocker with proper design geometry for the application. (Miller just happens to make application-specific rocker arms with correct design geometry for their intended application so that you don't have to sift thought rocker arms until you find the best one.)

By the way, note that I am referring to Mid-Lift as a geometry "standard," not a theory. Mid-Lift is an established, recognized, U.S. patented geometry standard which offers the greatest amount of valve train efficiency. It's not supposed to be a magic horsepower adder, or secret weapon or hidden trick, or anything like that. In fact to some extent it's really just common sense and logic. Mid-Lift standardizes valve train geometry; if all rocker arm manufacturers followed Mid-Lift then a given camshaft would essentially give the same results from one engine with brand x rocker arms as it would in the next engine with brand z rocker arms. It is an engineering standard which aims for the greatest efficiency attainable from a pushrod V8 rocker arm.

Also, the virtues of Mid-Lift caught the entire rocker arm industry with their pants down, scientifically and mathematically proving that all rocker arms not made to the Mid-Lift standard were of a less efficient design. And, since just one rocker arm company held the patent it meant that all the other rocker arm companies would have to license that patent from the rocker arm manufacturer that held it. In other words, 1) almost every manufacturer's rocker arms were proven sub-par by design geometry, 2) they now all had to redesign their rocker arms, and, 3) they also had to pay their competition for the permission to produce their own correctly engineered rocker arms. It's no wonder all the other rocker arm companies gathered together and tried to denounce Mid-Lift! In the meanwhile, Chrysler released a bulletin through their racing department mandating Mid-Lift in all their racing engines, and GM inducted it into their programs as well, etc.

With the Mid-Lift standard, a rocker arm with correct design geometry must be used so that both ends of the rocker arm (roller tip end and pushrod cup end) simultaneously achieve perpendicularity to their respective adjacent components. The advantages to this are numerous, including the areas of reduced valve train frictional losses, increased area-under-the-curve, less wasted motion of the valve train, improved valve train stability throughout the engines rpm range, etc.

So in a nutshell that's what it is about. I'll be happy to elaborate more at a later date so that it can be more deeply understood and appreciated by those who might not be familiar.

__________________

http://www.highflowdynamics.com

Last edited by Paul Kane; 03-05-2015 at 09:20 AM..

|

03-05-2015, 09:07 AM

|

|

CC Member

|

|

|

Join Date: May 2009

Location: American Fork,

Ut

Cobra Make, Engine: 66 Cobra

Posts: 930

|

|

Not Ranked

Not Ranked

Paul, thank you for posting that information. It is really hard to get good information on the subject. The difficult part with getting the right setup is first getting the right information and then finding the right rockers without having buy a bunch of rockers to try. I could find none of the main rocker manufacturers that have any information to make an informed decision. They just want to talk about strength and how good their bearings are, not geometry. I had no idea how far off the stock ratios are and now I am wondering how far off each brand of rollers are, not even considering mid-lift.

Thank you again for posting and please give us more information.

__________________

Wayne

"Everything is alive. If you get angry at a vehicle or the trans, it won't fix until you apologize and say you are sorry." "The vehicle always knows what it is doing and what the cause of it's bad feeling is. If you ask it humbly what the problem is, it will tell you. Then you and it will both be happy."

Gil Younger

Last edited by Wbulk; 03-05-2015 at 09:08 AM..

Reason: spelling

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -7. The time now is 09:13 AM.

Links monetized by VigLink

|